Laser etching is a non-contact technology. The etching process precisely changes the target material area on the packaging or product surface, resulting in a highly visible code. This process eliminates the possibility of printed information becoming obscure or unreadable during application. This laser ecting process will significantly change the performance displayed on the outside of the product. For example, laser etching will improve the corrosion resistance of metal parts and add new fashion aesthetic value. Laser etching technology is used in many industries, including aerospace and aircraft, automotive, and pharmaceutical industries.

What is laser etching

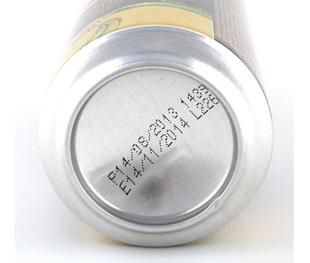

Laser etching is a process in which the high heat of the laser beam melts the surface of the material and produces text and images on the surface of parts and products. During etching, the laser heats and distorts the microscopic surface of the material. In this way, the laser-etched surface expands and produces texture. This can color the material in black, white or gray, and is the most effective way to permanently mark most types of materials. Laser etching is suitable for all kinds of metals. Because the mark is shallow, it is often used to etch thin materials. For example, production data matrix codes, serial numbers, barcodes and logos, etc. Other permanent laser marking solutions include laser marking and laser engraving.

The principle of laser etching machine for metal

The basic principle of laser etching is to focus a high-beam quality low-power laser beam (usually ultraviolet laser, fiber laser) into a very small spot. In this way, a high power density is formed at the focal point, so that the material vaporizes and evaporates instantly, forming holes, slits, and grooves. The laser etching machine for metal technology includes laser micro-nano cutting, scribing, etching, drilling and so on.

Features of metal etching machine

Metal etching machine has the characteristics of non-contact processing, high degree of flexibility, fast processing speed, no noise, small heat-affected zone, and can be focused on a spot with a very small laser wavelength. Using laser etching technology can obtain good drilling, scribing, etching and cutting dimensional accuracy and processing quality. In particular, the interaction with certain materials (such as polyimide) is a « cold working » of « photochemical action », and the effect of non-carbonization can be obtained. Therefore, laser etching is widely used in the processing of electronic semiconductor materials.

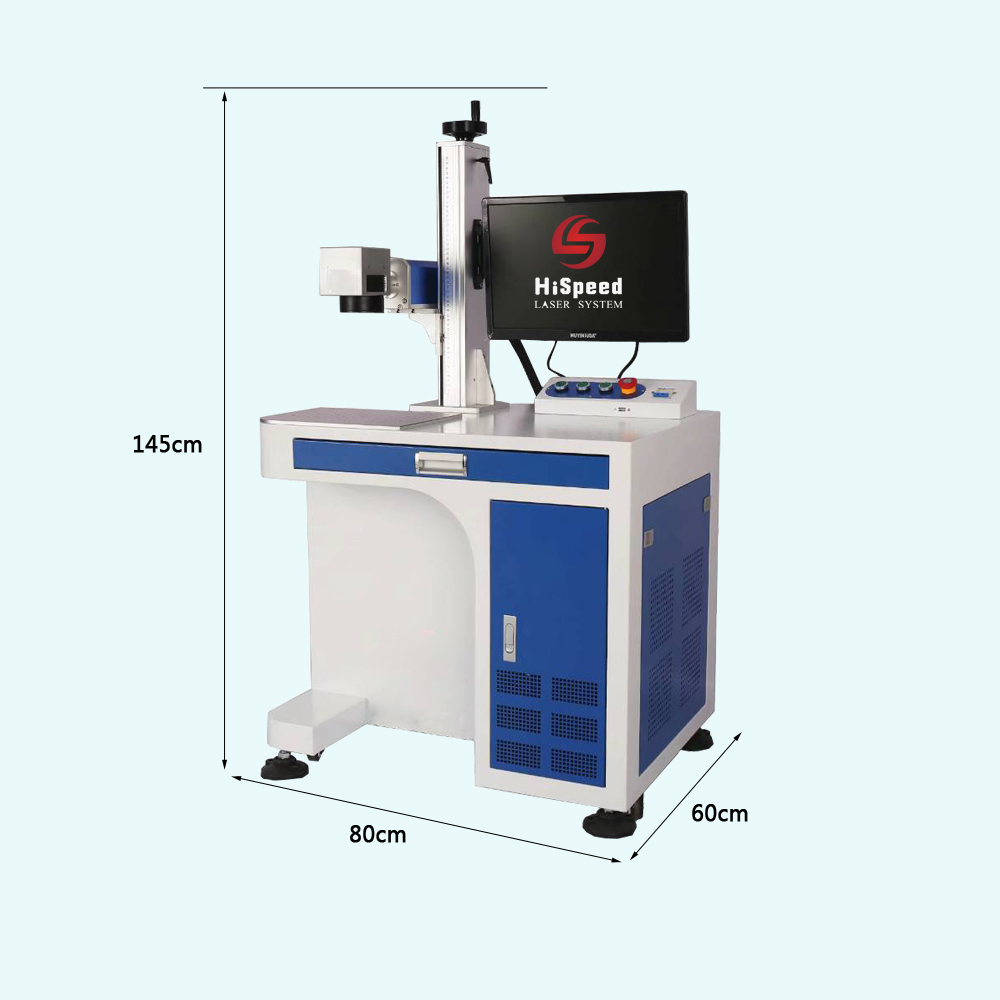

Metal etching machine

Lasers can etch various materials such as ceramics, polymers, glass, plastics and metals. Although metal etching machine can mark a wide range of materials, it is still dominated by metals. Laser etching technology can accurately and quickly leave marks on various types of hard or soft metals. In the production process of metal parts, laser etching has become a very popular finishing procedure. So what are the metal materials suitable for metal etching machine?

Aluminum:

Aluminum is a popular metal suitable for laser etching and cutting. The aluminum surface has high thermal conductivity so that the laser etching machine can etch aluminum at very high temperatures. Aluminum 380 and 6061 are the most common laser etching alloys. In addition, there are pure aluminum and anodized aluminum.

Steel:

Steel is a hard material and requires longer laser etching time than other metals. Higher laser etching speeds will produce white marks, while lower laser etching speeds will produce black marks. Steel tubes, sheets, pipes and springs are the most common products for laser etching.

Stainless steel:

Stainless steel is another prevalent metal in laser etching. The reason is simple: the etching effect is excellent and can meet photo quality requirements. The industry generally uses grades of 316 and 306 stainless steel for laser etching.

Anodized aluminum:

You can perform laser etching on aluminum without an oxide layer or laser etching on top of the oxide layer. In the former case, the etching is done before the aluminum is anodized and vice versa. The laser etching machine forms deep marks on the bare aluminum plate to ensure that the marks can be read after anodization.

Magnesium:

Industry uses magnesium when manufacturing lightweight parts. Laser etching can effectively create marks on such light legs. The laser etching machine can be specially configured to etch magnesium and magnesium alloys. Part of the material is removed from the surface to form high-contrast black and white traces.

Lead:

The thermal conductivity of lead and lead alloys is very low, which means that most of the heat generated by laser etching is retained on the surface. The melting temperature of lead material is also very low, so laser etching is easy to produce marks on the local surface. Anything made of metal needs an identification mark, so don’t forget to use a laser etching machine to complete the job.

Zinc:

Zinc is used not only for corrosion resistance but also for die casting. Laser etching is the only laser marking process that produces high contrast on zinc parts. It can be used regardless of the zinc alloy.

Non-metal etching machine

Laser etched wood

The laser etched wood will be elegant and smooth. You can use a laser etching machine for wood to engrave some wood nameplates or wood photos by yourself. A laser etching machine for wood is very accurate, and some businesses choose it to impress their QR code is also a good choice.

Laser glass etching machine

Laser etched glass pictures are a very popular form of laser engraving nowadays. Many couples will choose to laser etched photos on the glass to commemorate some important moments for both of them. Laser etching printer is no longer only for commercial use, but also more and more people will choose DIY.

Laser etching machine classification

Using a laser etching machine to mark metal is a very precise and clean form of metal processing. Laser etching machine for metal is done by laser, without any pre-treatment or post-treatment. Laser etching ensures permanent, acid and chemical resistance without damaging the metal surface. The fiber laser etching machine has low maintenance cost, does not use consumables, and can form high-contrast marks.

Nanosecond green laser etching machine for metal

Compared with infrared fiber laser etching machine, solar photovoltaic is the main application field of laser etching of this type of laser, especially for the more extensive application of PERC battery fool, especially for P1/P2/P3 scribing, etc. Compared with the fiber laser etching machine, it can etch finer lines, which is very suitable for the etching of P2 and P3 layers

Nanosecond infrared fiber laser etching machine

Ordinary pulsed fiber laser etching machine or adjustable pulse width fiber laser etching machine is used for ultra-fine etching of coated glass and film surface FTO, ITO, silver award, aluminum, copper, molybdenum aluminum molybdenum, tin alloy, nickel alloy, gold-plated glass and other materials.

Application of nanosecond infrared laser etching

Nanosecond UV laser etching machine

The main application area of UV laser etching machine is the electronics industry, such as sensor etching, usually also used for laser trimming, copper thin film etching is common. The advantage of the UV laser etching machine is that the etched lines are more refined without damaging the film, which can effectively ensure the conductivity and resistance requirements, and can be adjusted at any time according to the needs.

Application of UV laser etching

Thin film laser etching application:The ITO coating laser etching machine is a precision equipment that uses a laser to perform electrode etching on the ITO coating on ITO Glass and ITO Film. It can laser etch various patterns on a wide range of ITO coatings, polycrystalline films and other oxide films on glass and PET substrates. Especially suitable for laser etching of mobile phone touch screens.

Ultrafast laser etching machine (picosecond, femtosecond)

Use picosecond laser or femtosecond laser etching for inorganic materials or conductive metal materials(such as graphene, ink, P2 etching of perovskite battery, and carbon powder etching). The advantage of the ultrafast laser etching machine is that it has a less thermal impact on the material. Therefore, the line width of the etching is finer than that of the nanosecond ultraviolet laser etching machine, and the processing effect is better. It can also perform laser etching on multilayer materials, such as perovskite batteries.