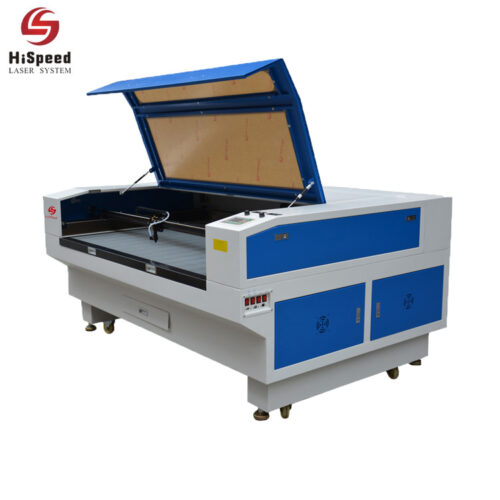

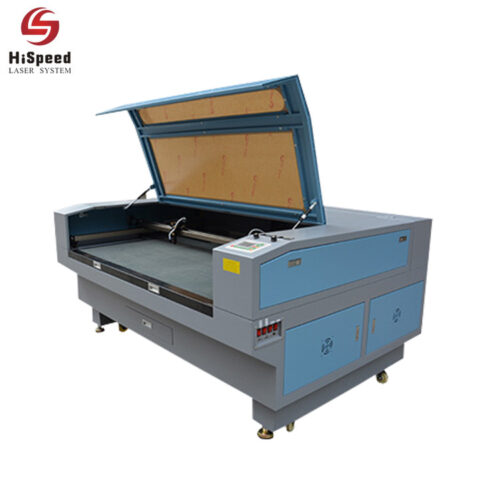

CO2 Laser Cutting Machine

CO2 laser cutter is a CNC laser cutting machine that uses CO2 laser to cut wood, plywood, fabric, plastic, leather, paper, and thin metals, which is widely used in industrial manufacturing applications, school education, home business, etc. We’ll offer you the best CO2 laser cutting machines to fit your custom laser cutting requirements, such as 80w Laser Cutter with Panoramic Camera Automatic Appearance, Acrylic MDF Plastic Fabric CO2 Laser Engraving Cutting Machine, 150w CO2 Laser Cutter Engraver, etc. In Hispeed, you can get the best CO2 laser cutting machine price.

What is CO2 Laser Cutter?

The CO2 laser cutting machine uses CO2 and other gas-particle as the laser medium and cuts objects. The CO2 laser cutter cuts the materials having the height in between 6mm to 20 mm. The higher the power can cut thicker materials. This laser cutting system can cut any solid materials such as acrylic, wood, paper, metals, plastic, and all other elements.

As we have mentioned in CO2 laser engraving machine articles, the more the power supply and amplification, the more deep a machine can cut. So, depending on the power supply, there are a few types of CO2 Laser Cutter, including 40w CO2 Laser Cutter, 50W CO2 Laser Cutter, 60W CO2 laser Cutting Machine for Metal, and 100W CO2 Laser Cutter. The history of CO2 Laser Cutting Machine started from the nineteenth century; still, it’s popular in the market.

How does CO2 Laser Cutter Work?

Typically the overall laser system consists of two major units. One of them is the controlling unit, and the other one is the laser-shooting unit. By the way, the energy source located inside the controlling unit. Similar to the CO2 laser engraving machine/ CO2 laser marking machine, the laser comes from the laser medium contained in a protecting box. Here, the laser medium is surrounded by two mirrors. One of them has a pore for the photon transfer. In the presence of the high power energy source, this laser medium produces lots of photons, which is called a laser beam. This laser beam then travels to the laser gun through the fiber cable. In the laser gun, the photons then get mixed with the assist gas oxidizes the photons. The photon then goes through the amplification lens. Finally, It hits the surface of the materials.

Based on the density of the photons and the amplification lens, the depth of the cutting depends. Usually, the CO2 laser cutting machine has a higher frequency than the other CO2 laser cutters.

How to use a UV Laser Marking Machine?

We already mentioned that the laser machine has two different units. They have separate plugins. Before using our CO2 Laser cutter, we must check all of our plugins are connected correctly. On the other hand, the laser gun also has a few plugins that are directly related to the controlling unit. We should check that too.

However, using a USB cable, we can connect our computer to the CO2 Laser cutting machine. Make sure you have installed the right driver for the laser cutting device. The software is straightforward and straightforward to deal with. You can draw your design on the software, or you can convert your CAD file too. And then go to laser gun again.

Put your object on the working stage, and point out the marking using the software. Check out if the laser gun is at the zero references or not. If your object is 20mm thick, put up your laser gun 20 mm above the zero references.

It is a laser cutting process, so do not forget to wear safety glasses. The laser beams are a kind of light, so do not put any reflective object besides your laser machine. Do the operation with caution.

How to Maintain the CO2 Laser Cutter?

We know that we do not want to buy a CO2 Laser cutting machine for a limited time frame because it is so expensive. So we must use it with care. Therefore, we strongly recommend focusing on these maintenance sections.

- Cut off the power supply after the operation.

- When the machine is turned on, Do not perform the maintenance.

- While your machine is off, clean up all the dust.

- If you feel any unusual activities, cut off the power. Check back all the plugins and wirings.

- Do not put any object on your machine. It might distract the cooling system.

- Put back the cap on the focus lens after your maintenance.

CO2 Laser Cutter Advantages and disadvantages

The advantages of using a CO2 Laser Cutting Machine are:

- This laser cutter can cut all the solid materials such as metals, plastics, papers, acrylic, paper, wood, etc.

- It is fully automated, so we do not need a human hand for manual cutting.

- It is easy to access, just put the design on the computer, and that’s it. Wait for the machine delivers your product.

- It is safe and highly reliable.

- No need for any labor to operate anything.