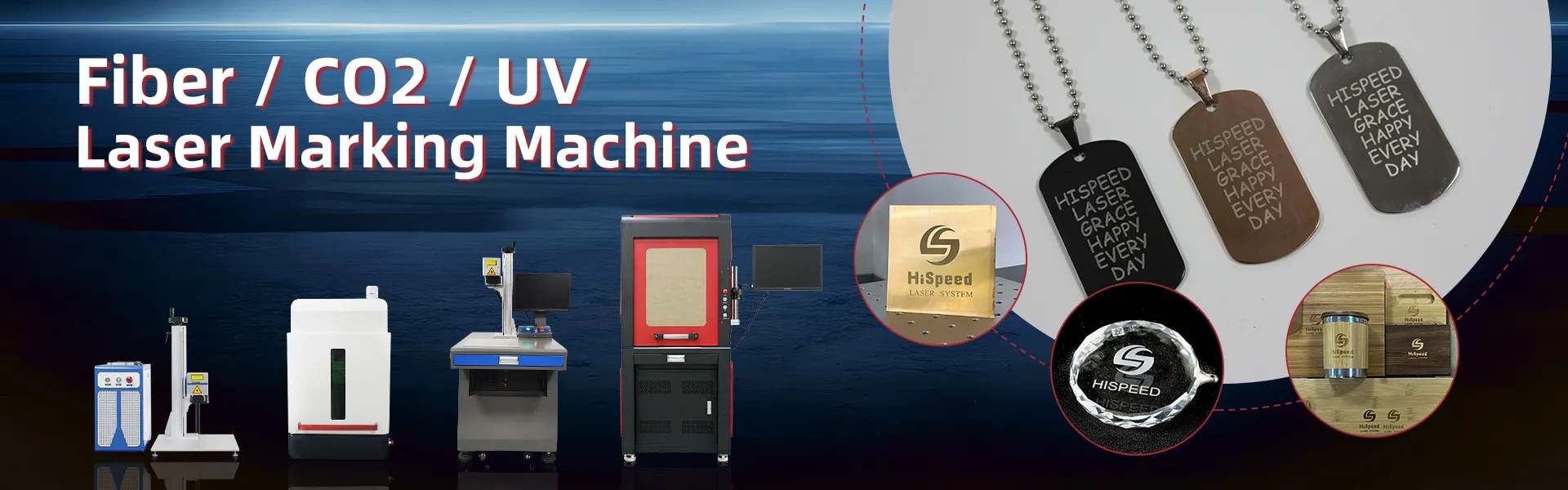

Laser marking machine is also known as the laser code machine, laser marker, and laser symbol machine. And now, let’s together have a closer look at the differences between the several laser markers.

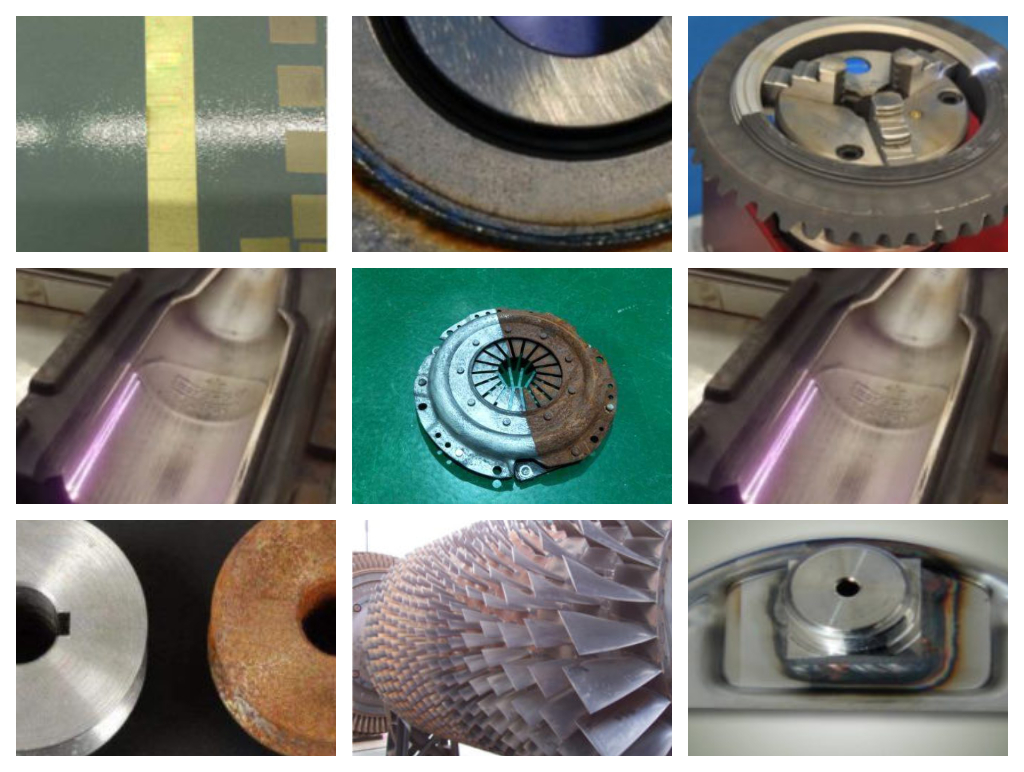

At first, it comes CO2 laser marking machine. Currently, CO2 laser marking machine is usually equipped with the CO2 RF laser tube, whose service life can be up to 50,000 hours. Generally, the marking speed of CO2 laser marker can reach 7,000 mm/s. CO2 laser marker is greatly suitable for marking on most non-metallic materials, i.e. paper packaging, plastic products, leather cloth, glass, and ceramics.

Secondly, it comes with a UV laser marking machine. UV-laser marking is especially appropriate for sensitive materials like silicone because surface structures are only slightly affected. At the same time, its short wavelengths enable excellent marking results. Even for micro text(text height under 0.1 mm), a UV-laser can attain a line width of under 10 µm. On the glass, a UV-laser can also provide filigree and brilliant marks of high quality. Drinking glasses or crystal watches keep their smooth surfaces, as a UV-laser produces micro-cracks of much smaller dimensions as compared to for example a CO2-laser.

Thirdly, it comes with a green laser marking machine. Green laser marking is designed to mark highly reflective materials or highly sensitive substrates like silicon wafers with ease and precision. They operate in the visible light spectrum at 532 nm (green color light). It’s perfect for softer plastics, PCB Boards, IC Chips, and for scribing or marking of Solar Cells of various material compositions.

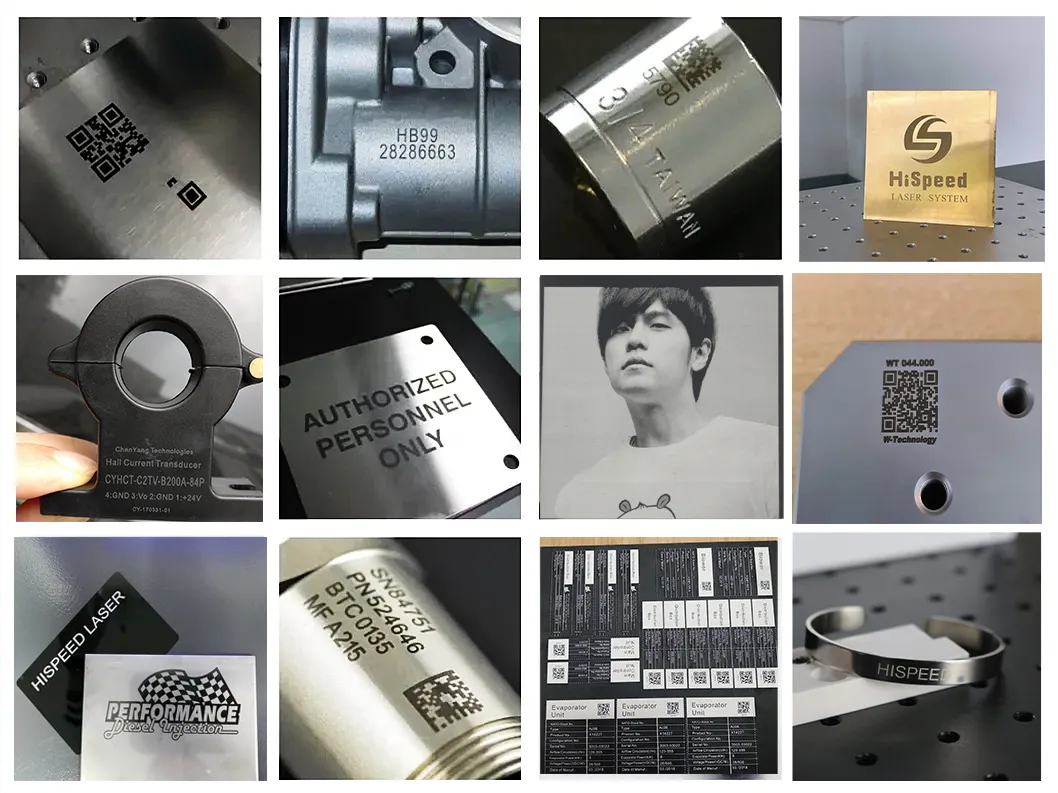

Last but not least, it comes with fiber laser marking machines. They are most suitable for high-contrast markings, such as the metal annealing, etching, and engraving. The extremely small focal diameter enables them to be the ideal choice for the lasting marking of serial numbers, barcodes, and data matrix on metals. Fiber lasers find wide applications on the product traceability ( direct part marking ) and identification applications.

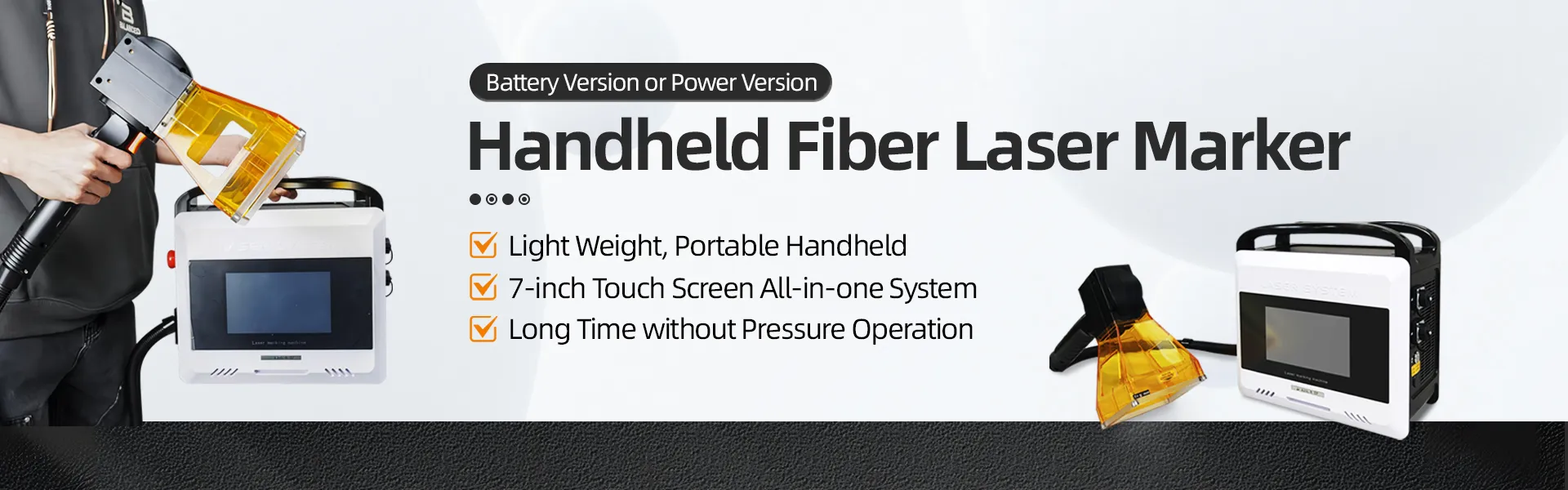

Fiber laser includes a pulsed laser and continuous-wave laser.

For the laser marking process,pulsed laser is the one. It releases the beam at a set rate. They’re ideal for laser marking applications because they boast a higher making speed.

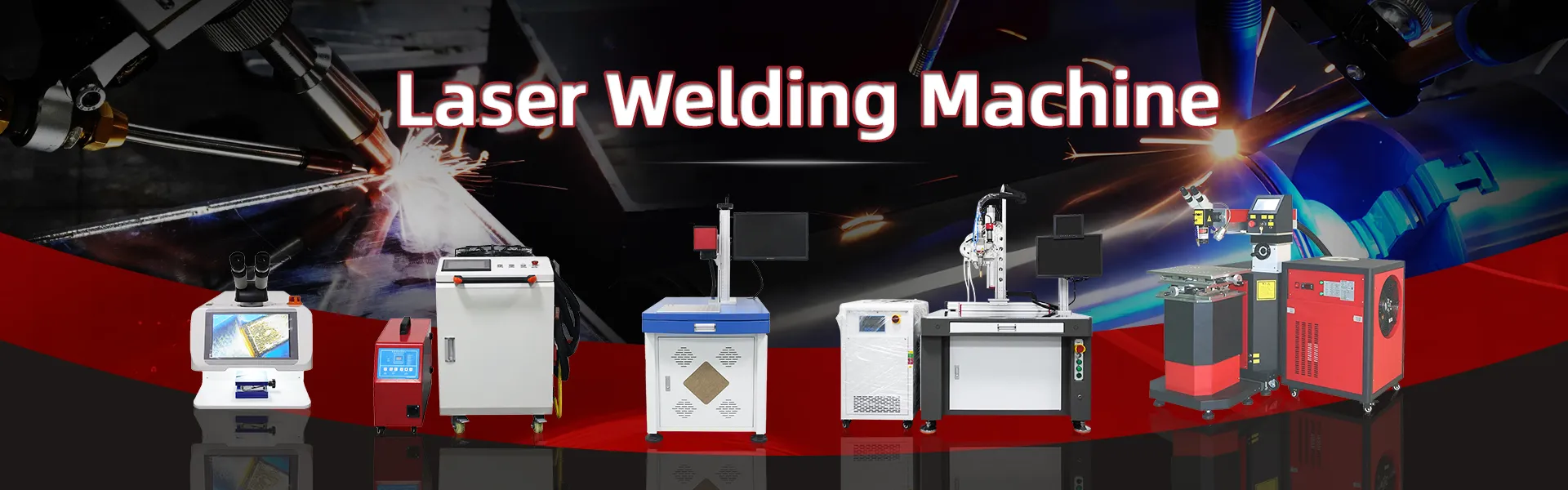

As to the continuous-wave laser, it continuously emits the laser beam. They are more adapted to other laser applications, like laser cutting, welding, and drilling.