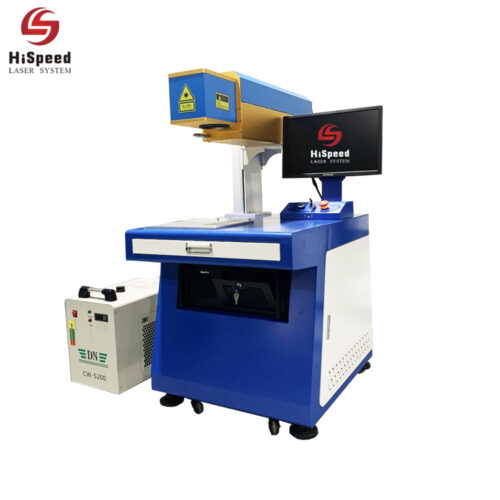

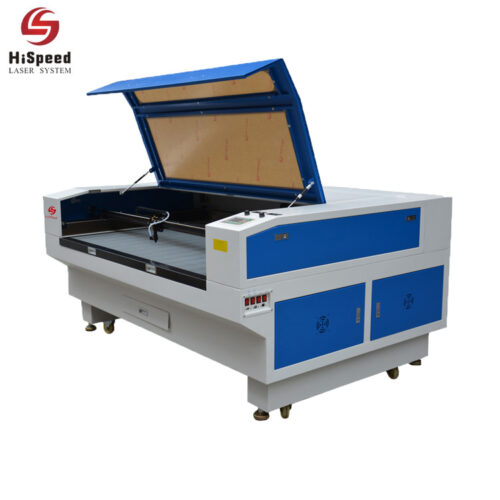

Laser Marking Machine Manufacturer – Hispeed

Hispeed Laser provides you with professional industrial laser solutions.

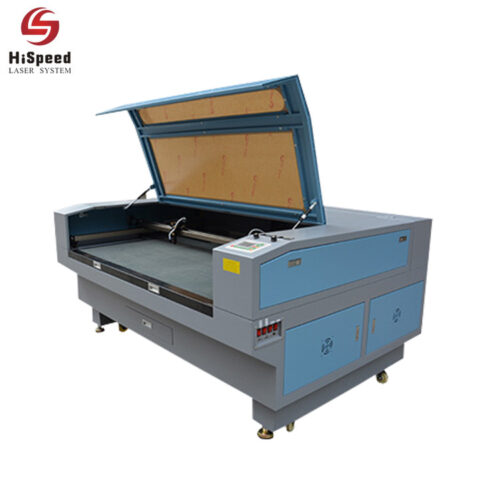

We offer:

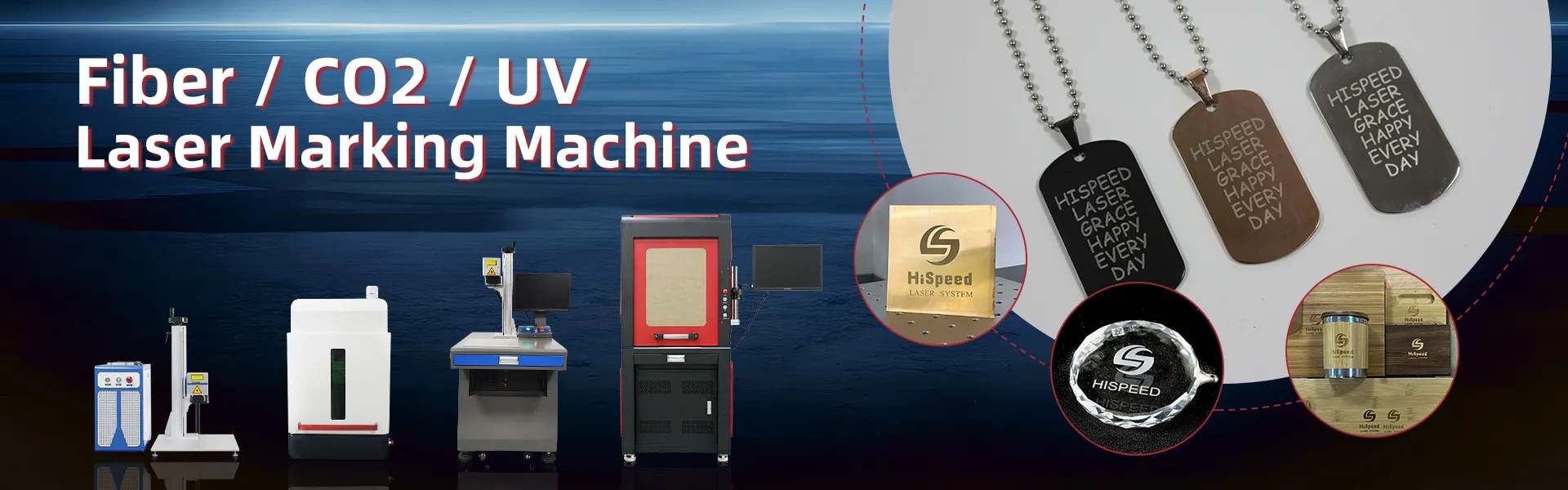

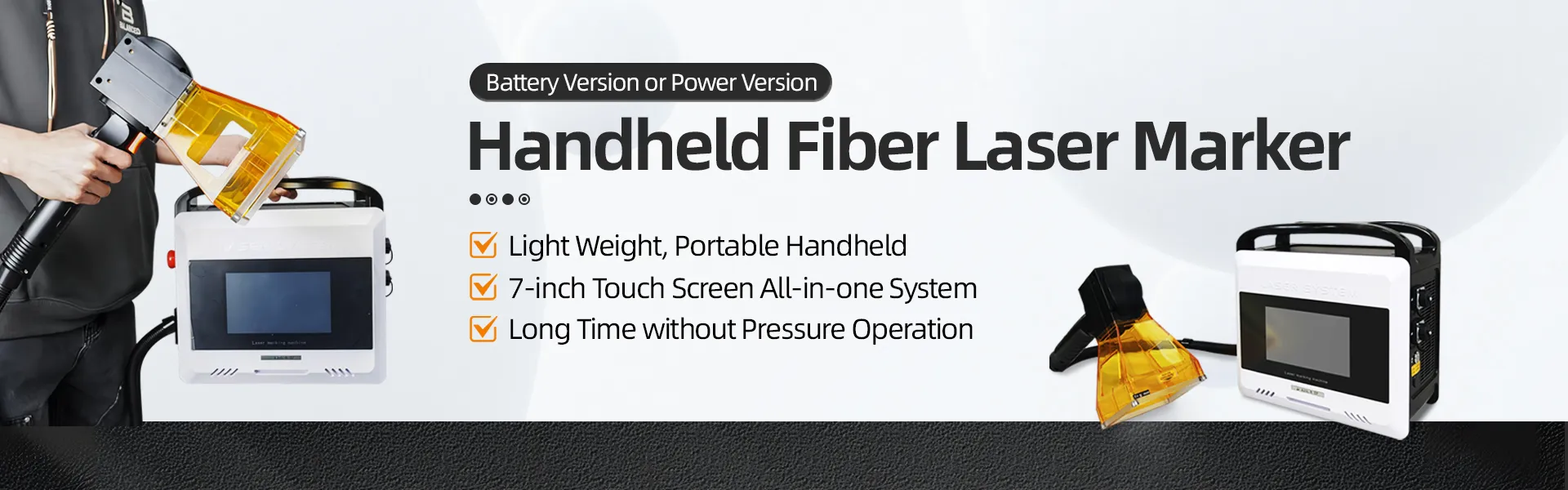

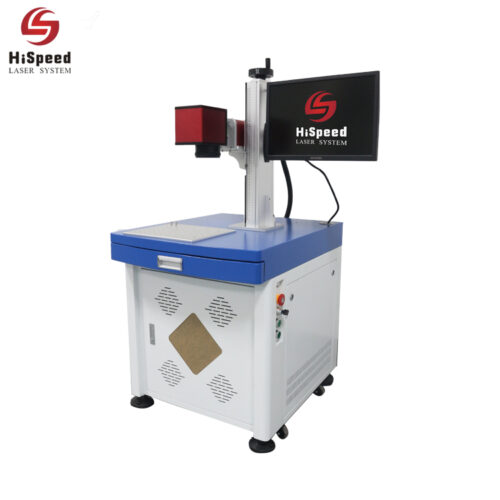

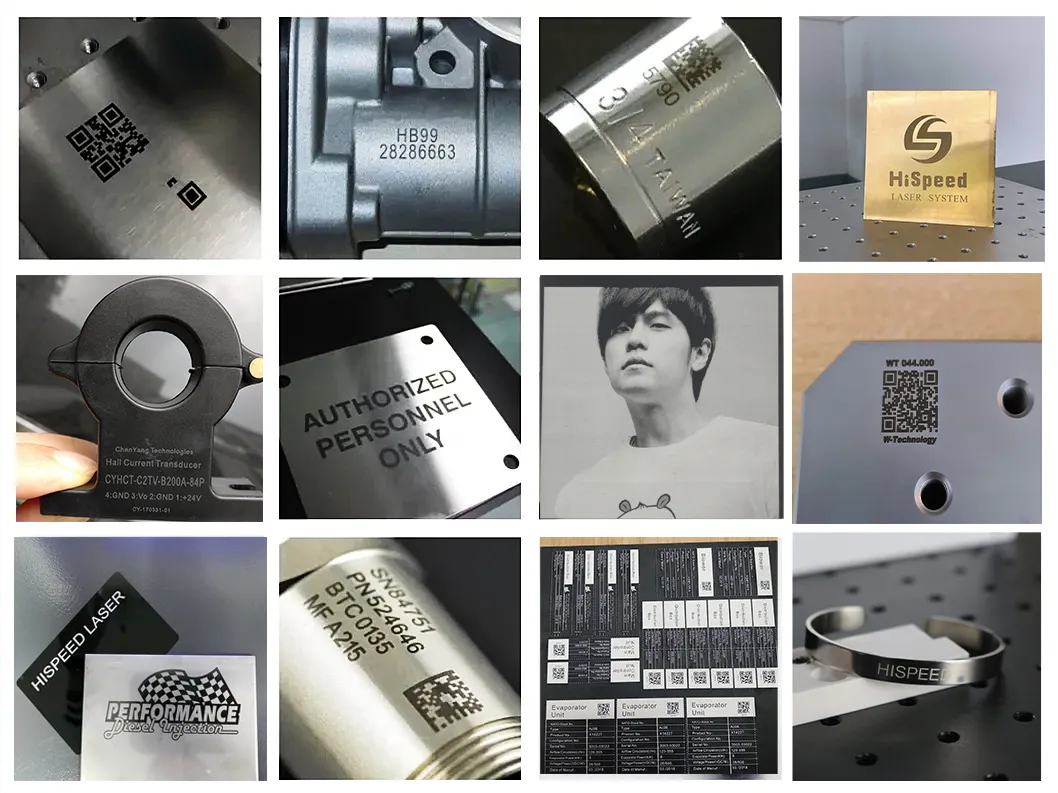

- Laser marking machines

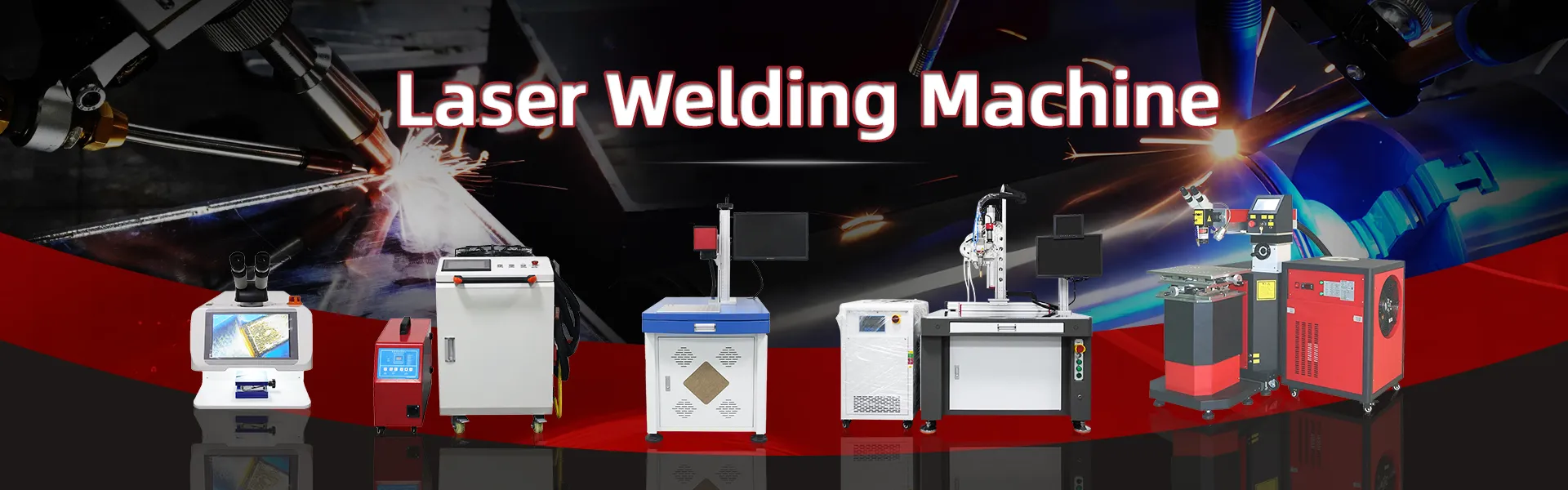

- Laser welding machines

- Laser cutting machines

- Laser cleaning machines

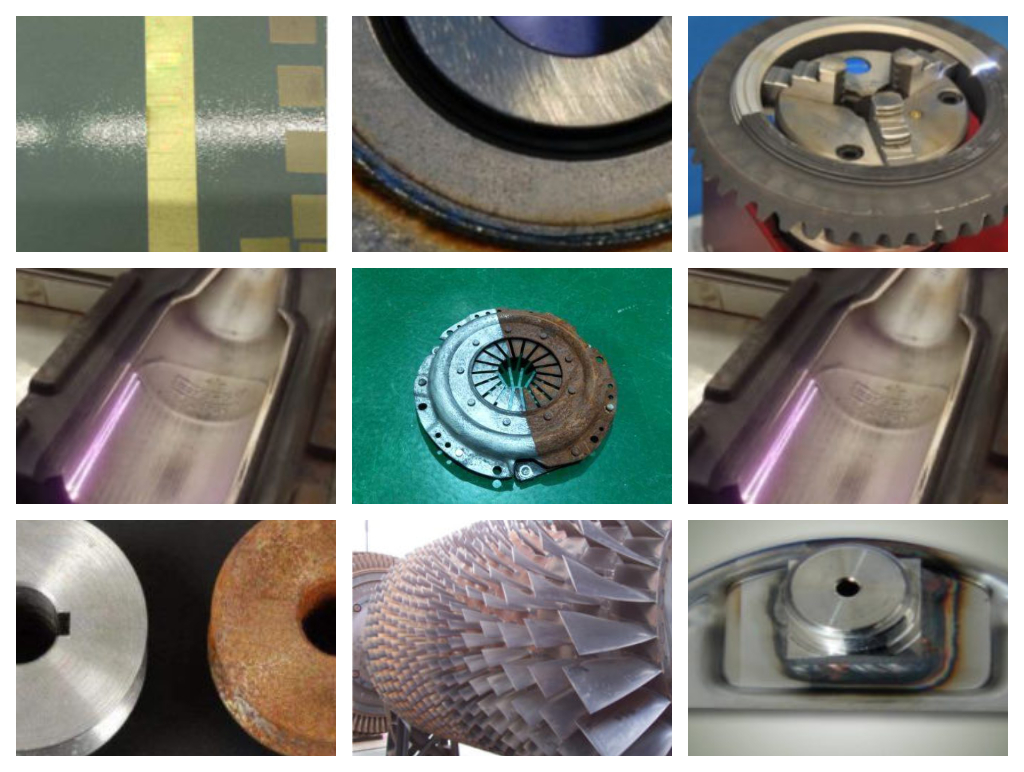

Our main products are laser marking machines, which we supply annually in over 1,000 units. To ensure everyone’s trust in our product quality, all Hispeed products have passed the international certifications of CE, UKCA, and FDA.If you need laser machines for 3C electronics, auto manufacturing, medical equipment, jewelry, or food packaging, choose Hispeed. We are your trusted partner.