MOPA Fiber Laser Marking Machine

100w fiber laser marking machine accessories

MOPA Fiber Laser Marking Machine Technical Specifications

| Laser type | Hispeed laser machine with JPT laser source |

|---|---|

| Laser Brand | F70, F100, F160, F210, F254, F290 (Optional) |

| Field Lens | 30-50% |

| Hatch Line Distance | 0.01mm |

| Pulse width | 30-100ns |

| Frequency | 200KHz |

| Speed | 100mm/s |

MOPA Fiber Laser Marking Machine Standard Accessories:

Configulartion and Specifications of the Hispeed MOPA fiber laser marking machine system

- JPT Brand Laser Source,20W-120W power options

- Hispeed-Galvo Scan Head

- F-theta Lens F160-F254

- JCZ EZCAD Marking Control Card and Software

- Industrial Computer and Screen

- Foot Pedal

Mopa laser engraver more information

- Two years warranty

- CE certificated

- MOQ 1 set

- Production leatime:3-7days

Mopa fiber laser settings:

| Color | Pulse Width | Frequency | Hatch | Speed | Power |

| Purple | 2ns | 400KHz | 0.001 | 1000 | 55% |

| Blue | 4ns | 200KHz | 0.002 | 2000 | 80% |

| Green | 13ns | 500KHz | 0.001 | 1500 | 40% |

| Yellow | 13ns | 400KHz | 0.002 | 2600 | 80% |

| Cyan | 13ns | 350KHz | 0.001 | 1500 | 40% |

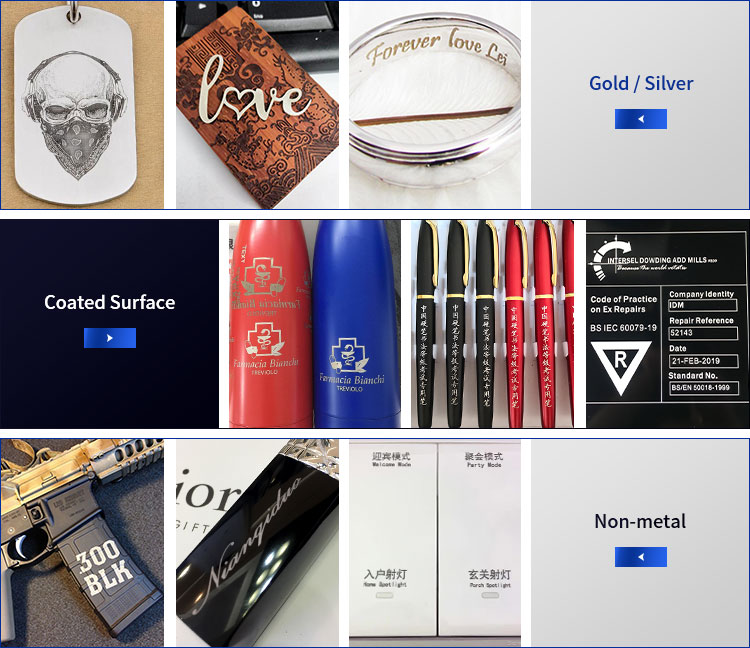

What we can do with MOPA fiber laser marking machine?

Product Introduction of 20w 30W 50W 60W 100W fiber laser marking

What is a MOPA Laser?

The light of marking lasers is generated in pulses. Generally, the pulse duration is non-adjustable. What is special about a MOPA laser is that its pulse duration is variable: Long or short pulses can be adjusted.Take an example, the stainless steel material can change the color of the surface layer of the material by adjusting the pulse width,so as to obtain a decorative effect with different colors. MOPA laser marking machine can do black and white marking on most metals and plastics,black marking on anodized aluminum, color marking on stainless steel and titanium.Advantages of MOPA laser For short pulses and lower pulse energy, the material is heated less and the area of the heat affected zone is reduced. This results in more advantages and possibilities for laser marking metals and plastics.

What we can do with MOPA laser?

MOPA fiber laser marking machine can do black and white marking on most metals and plastics, black marking on anodized aluminum, color marking on stainless steel and titanium.

1. MOPA laser color settings on stainless steel

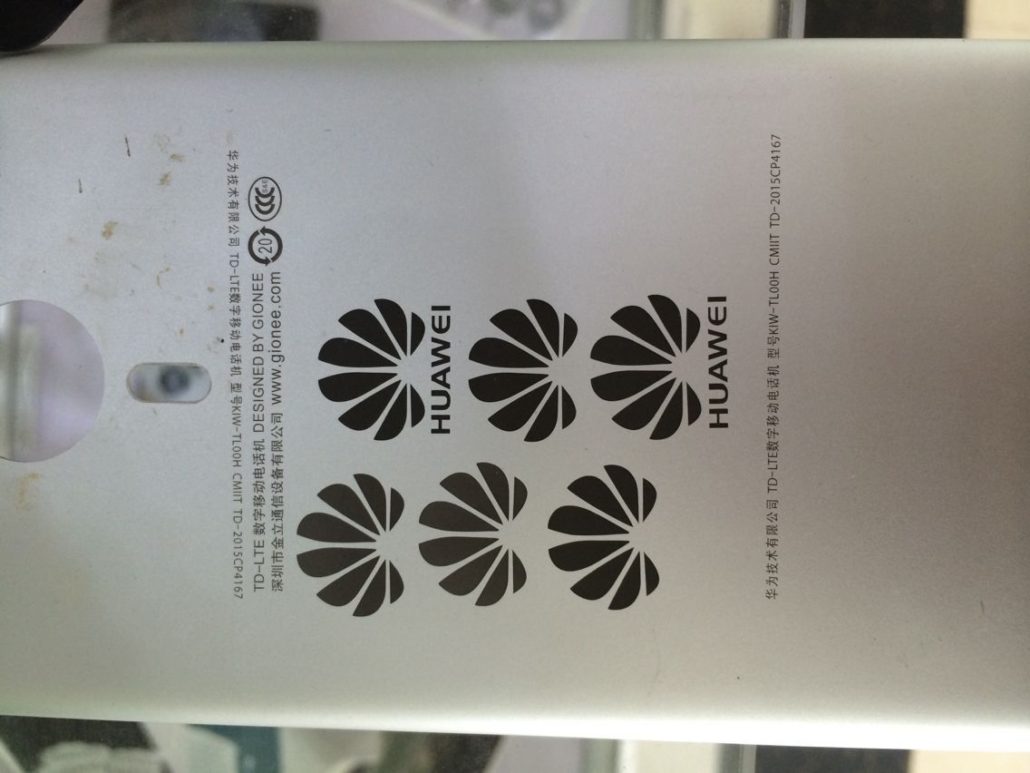

2. Black marking on anodized aluminum

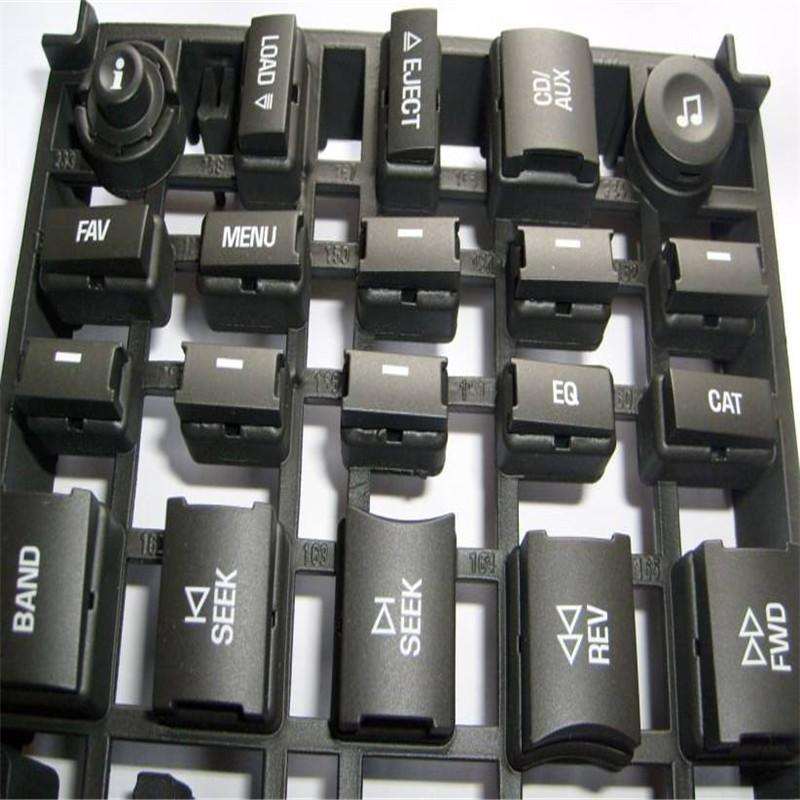

3. White marking on black plastic

4. Black marking on white plastic

Hispeed MOPA Laser Marking Machine Systems are built-in with a JPT MOPA brand laser source.

Application Examples of Hispeed MOPA Laser Marking Machine System

Colorful Marking on Stainless Steel

The principle of laser engraving color development:

- Generate colored oxides;

- Generate colorless transparent oxide film, generate interference, and show color;

- Generate colored oxide and colorless oxide film at the same time.

Laser Type:Hispeed laser machine with JPT laser source

Laser Type:Hispeed laser machine with JPT laser source

- theta lens: F=254mm

MOPA fiber laser settings Analysis:

Under dense hatching line space, small and medium pulse widths, and high frequency, color development is mainly affected by frequency and power.The differences in these colors are mainly affected by the laser’s single pulse energy and its spot overlap on the material.

2.Black Marking on Stainless Steel:

Marking with mid-pulse width and high frequency will not damage the surface protective layer and has no touch feeling.

MOPA fiber laser settings Analysis:

Blackening of stainless steel is mainly to produce black oxides. The JPT MOPA laser sources have a more pure black effect under large field lens and high frequency, which is not easy to wipe off.

3.Black Marking on White Plastic

- Laser type: Hispeed laser machine with JPT laser source

- F-theta Lens: F=163mm, 210mm

- Power:40-70%

- Hatch Line Distance:0.025-0.04mm

- Pulse width:60-100ns

- Frequency:15-30KHz

- Speed:800-1200mm/s

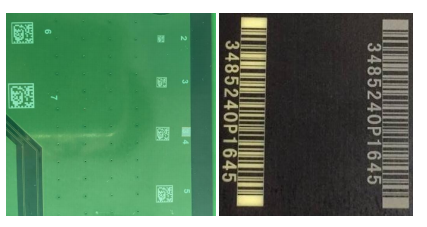

4.Marking barcode and data matric on PCB board

Compared with traditional sticking or printing, Barcode or Two-dimensional codes marked by Hispeed Laser are more clear and difficult to reomve.Bar codes can be automatically generated when marking, and code jumps automatically. It is suitable for marking of assembly line products with high efficiency.

MOPA fiber laser settings parameters:

- Laser type:Hispeed laser machine with JPT laser source

- F-theta lens:F=210mm

- Hatch mode:

- Power:50-70%,

- Hatch line space:0.02-0.04mm

- Pulse width:6-30ns

- Frequency:30-80KHz

- Speed:1500-2500mm/s

MOPA fiber laser settings analysis:The surface material of the PCB is epoxy resin, which is more sensitive to laser energy. M7 use small pulse width and medium frequency. They can be marked with clear bar codes and two-dimensional codes for easy scanning.Didn’t find the suitable laser application for your products?Contact Hispeed Laser Now!

Mopa fiber laser marking machine after sales service:

- 1.All of our machine will be fully-checked by our quality control department before the shipment.We guarantee all of our laser machines have a one-year warranty (quick-wear parts notincluded).

- Training details: operation principles, system and structure, safety and maintenance, softwarethe processing technique, and so on.

- Numerous feedback from our clients have proven that our laser machines are stable inperformance with rare malfunction. However, we would like to handle it as follows oncemalfunction occurs:a.We guarantee that we will give you a clear reply within 24 hours.

b. Customer service staff will assist and guide you to analyze the malfunction in order to locatethe cause.

c. If the malfunction is caused by improper operation on software and other soft faults, we willhelp solve the problem on line.

d.We will offer plenty of online supports, just like detailed technical and installation instructionsby email,video, telephone. (Training by team viewer)