Are you seeking to purchase a laser machine to process various materials? Do you know the different types of laser machine in the market? Generally speaking, there are three kinds of laser machines, namely a laser engraving machine, laser marking machine, and laser cutting machine.

After the successful R&D of laser technology, the various types of laser machines have also enjoyed a boom. Such laser machines are high-tech products. They find a wide of applications in such industries as the advertising, craft, mold, construction, printing, and packaging.

The term laser engraving machine and laser marking machine is easily confused for those who lack relevant expert knowledge or practical experience.

But, today, this guide places a detailed explanation of the differences between the laser engraving machine and laser marking machine for your reference.

Ⅰ. Definition: Laser Engraving Machine VS Laser Marking Machine

What is Laser Engraving Machine?

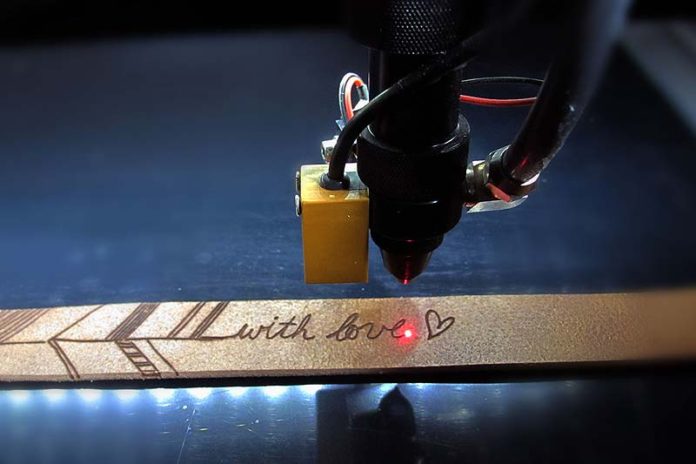

A laser engraving machine is one that resorts to engrave materials via the laser engraving technology. The laser engraving machine is totally different from the traditional processing method, i.e. mechanical engraving and the laborious manual engraving.

In the course of processing materials, the laser engraving machine doesn’t either use inks or involve a tool bit that contact with the materials. This is much better than those machines that need to regularly replace the inks and bit heads.

It utilizes the heat energy of the laser to engrave materials to be processed. The laser engraving machine features a higher engraving accuracy and faster engraving speed.

Plus, the laser engraving machine can also produce very refined and vivid engraving products. It is deserved the mention that these products are not inferior to those made by the craftsmen of rich experience.

What is laser Marking Machine?

A laser marking machine is a kind of machine that processes materials via the laser marking technology. The laser marking machine is mainly great for handling metal material. Hence, it is also known as the metal laser marking machine.

The laser marking machine only makes the color changing in the inner part of the materials. That means burrs caused by the machine processing will not bring changes to the material surface.

The laser marking machine features a lot of advantages, such as good quality of beam light, small size, prolong service lifespan, and flexible and convenient installment. It is mainly suitable to process the following materials, such as metals, plastics, electronics, tobacco, vase, etc. Regardless of what kind of material and marking method, the laser marking machine is flexible in marking any contents and shapes.

Ⅱ. Working Way: Laser Engraving Machine VS Laser Marking Machine

How Does Laser Engraving Machine Works?

When processing the materials, there are three major critical parts, namely the laser, controller, and surface.

- Firstly, the surface refers to the surface of materials to be processed.

- Secondly, the laser serves as the function of the “pen” or “pencil”. It is responsible for creating the object by concentrating light of high-power on the material surface.

- Finally, the function of the “controller” is very explicit according to its written meaning. This part serves as an « arm » to manipulate the « pen » moving over the material surface. Moreover, it can adjust the laser power as your requirements.

All the above movements are controllable by the design file you created. When processing the materials, the « controller » and the laser can work in the right way as the design file.

How Does Laser Marking Machine Works?

Different from the laser engraving machine, the laser marking machine is less likely to alter material surface from abrasion and burrs.

Generally speaking, the laser marking machine can work as to the following two publicly accepted principles:

“Hot Working”:

The laser marking machine could give off a laser beam of high density – a focused energy flow. This laser beam irradiates on the surface of the material to be processed. The surface of the material takes in the laser beam and then cause the increased temperature. In this way, the materials being processed may see the following physical or chemical changes, such as evaporation, metamorphosis, melting, ablation, etc.

“Cold Processing”:

The laser marking machine possesses the very high load energy photons. Such photons can breach the chemical bonds in the materials or the medium surrounding materials. Different from the « Hot Working », the cold processing method is a process of cold stripping in nature. This method only causes damage to the chemical bonds rather than generating a byproduct – « thermal damage ». In other words, either the inner part or exterior areas of materials will not see deformation from overheating.

Ⅲ. Applications: Laser Engraver Machine VS Laser Marking Machine

Four Applications of Laser Engraving Machine

The laser engraving machine has enjoyed wide utilization among various industries. The following are the four main industries in which a laser engraving machine applies.

Printing and Packaging Industry

In this industry, it often involves the addition of various designs on packaging, such as trademark, logo. The packagings typically consist of paper, plastic, and wood.

As applying a non-contact processing technology, such a laser engraving machine has no direct contact with paper products. Therefore, the materials will not see mechanical deformation, abrasion, and loss.

Hardware Processing Industry

In this industry, there is often a need to conduct engraving design on stainless steel or other metal products. With a laser engraving machine, you can easily achieve the high-accurate engraving processing.

Even when processing some hardware parts, the original accuracy will not suffer any influence.

Advertising Industry

The advertising industry plays an indispensable role in the modern cultural industry. In the circle of the advertising, in general, the products to be processed cover lightboxes, street signs, signboards, etc. The products mentioned above mostly consist of wood, plastics, and high-density board.

Plus, there is often an occasion that the product must be designed as customer’s requirements. If you resort to a laser engraving machine to accomplish the task, you can get the desired graphics and model effects.

Leather Processing Industry

In the traditional leather industry, the processing of materials is often completed by hand or electric cutting technology. However, there has always been a predicament of slow speed, low efficiency, and serious material waste.

However, with a laser engraving machine, you just input the graphic and sizes to be handled. And then the laser engraving machine will process the material into the finished product according to the design file you created.

Four Applications of Laser Marking Machine

The laser engraving machine has enjoyed wide utilization among various industries. The following are the four main industries in which a laser marking machine applies.

Food Industry

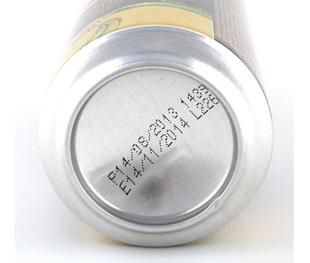

In the food industry, the laser marking machine is mainly applicable to mark the stuff with a beam of the laser. And it can give a mark on the food surface, such as patterns, two-dimensional codes. With it, there will be no unnecessary material waste and pollution. Moreover, the laser marker can ensure high precision and degree of clearness.

Electronic Industry

The laser marker finds a wide of applications in the IT industry. Just as an old saying, a little error may result in great loss. It is also the same in the electronic industry, everything needs to be highly precise.

Packaging Field

We all know that the laser marker can be also called as a laser inkjet printer. The laser marker can mark and identify the material. And then it can mark clearly the production date, two-dimensional code and so on. Hence, it enjoys a wide welcome in various industries, i.e. food, wine bottle cap, beverage packaging, cigarette packaging.

Metal Areas

Laser marking machines are applicable to process various metals, especially for the marking of the electronic hardware accessories and electronic components. Plus, for materials with high friction, such as automobiles, ships, machinery, the laser marker can be durable for quite a long time.

IV. Advantage of Laser Engraver Machine VS Laser Marking Machine

Advantages of Laser Marking

Laser marking has many advantages over other marking methods, for example.

Laser marking has higher marking precision/accuracy. It can do the engraving very well, whether it is marking 2D codes or other items that require high accuracy.

The laser marking process does not cause much pollution to the environment. The laser marking process produces much less waste because it does not require the removal of material from the workpiece to create the desired mark.

Advantages of laser engraving

Laser engraving also offers a variety of advantages over other marking processes, such as.

Laser engraving can have a wider range of depths. Laser engraving marks can be achieved at different depths, from shallow to deep. Laser engraving is fast in marking. Laser engraving is the fastest way to produce marks made by laser. And it is durable. The marks produced by the laser engraving process remain highly visible even under harsh conditions.