Heat Transfer Vinyl Introduction

Heat Transfer Vinyl refers to a thermal transfer film that needs to be engraved/cut during the thermal transfer process. Under the combined action of heat and pressure, it is separated from the carrier film together with the release layer and firmly transferred to the surface of the substrate with special functional printing film.

- Multi-layer Structure:

Including base layer, printing layer and adhesive layer, and some also include release layer and hot melt adhesive powder layer

- Common Materials:

TPU, PVC, Silicone, Reflective Material, Flocking Material

- Application Scope:

Usually used in the production of clothing accessories, trademarks, logos, etc.

- Features:

Elasticity, covering power, temperature resistance

Customer’s Description of the Material:

– They are PU and silicon attached with thermal transfer.

– We usually work with PU, Silicone, and Fabric (100-200 microns).

Industry Terminology:

– Thermal transfer PU silicon fabric

– 3D silicone heat transfer label marking machine

– Heat transfer T-shirt film/vinyl PU for T-shirt/clothes/fabric cutting

– Heat transfer label

Application:

– The Heat Transfer Vinyl is cut and marked by a laser marking machine, and then used to make personalized decorations for clothing, shoes, hats, bags and other products.

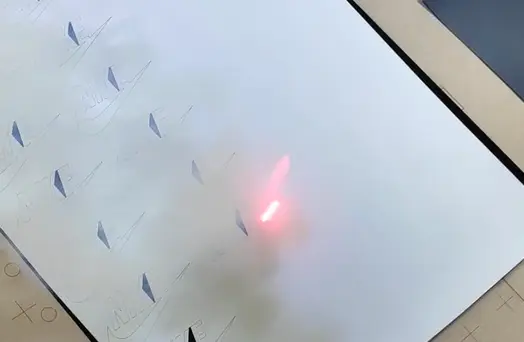

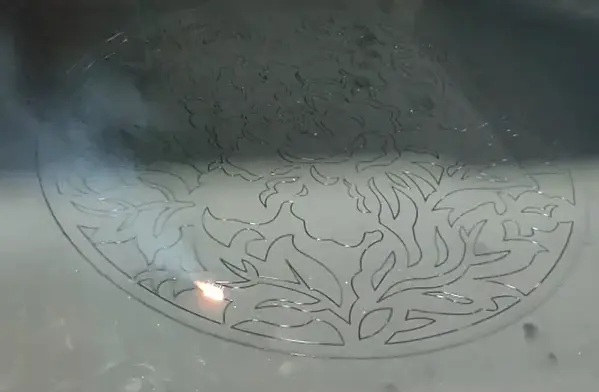

– The laser marking machine uses a high-energy laser beam to irradiate the surface of the lettering film, removes the material by ablation or melting, and forms the required pattern or text.

– The laser-processed lettering film has good water resistance, sun resistance and wear resistance, is not easy to fade, and has a good feel.

Heat Transfer Vinyl Production Process

- The production process of Heat Transfer Vinyl usually includes design, cutting, film application, engraving, film stripping and polishing.

- The laser marking machine plays the role of engraving and cutting in this process, and can quickly and accurately transfer the design pattern to the lettering film.

- The whole process is fast, accurate, and can be automated, making it suitable for large-scale production.

Design → Cutting → Film Pasting → Engraving → Film Stripping → Polishing

Laser Marking/Engraving/Cutting:

- Laser technology is used for the processing of Heat Transfer Vinyl, including engraving patterns, cutting shapes and marking.

- The advantages of laser processing include fast speed, high precision, easy operation, and the ability to handle complex pattern designs.

- Laser marking machines can be applied to a variety of materials, including PVC, TPU, PU matte, luminous, laser soft metal, reflective, flocking and other lettering film materials.

Laser Machine for Heat Transfer Vinyl

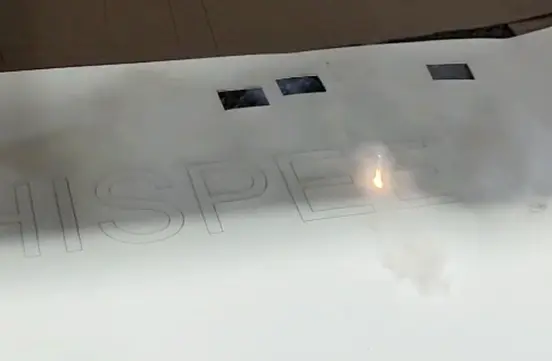

The super lettering film laser marking machine uses a super large spot three-dimensional dynamic system, and the processing speed is 25%-30% faster than that of ordinary laser marking machines. The beam quality is finer, and the cutting effect is more delicate and beautiful.

Machine Configuration

250W CO2 Large Range Marking Machine

600*600mm – 800*800mm working area

Machine Features:

- Clean cutting edge, no burning mark

- High accuracy digital scanner system, make sure the engraving accurate

- Using 3D dynamic focusing scanning system, focus distance can be adjusted automatically through software control

- Small laser beam, the minimum cutting line width can reach to 0.15mm.

- Automatic operation, suitable for large-scale production

Welcome to contact us for more information about laser marking machines for Heat Transfer Vinyl