Laser technology has upgraded the world of precision machining and crafting. It can achieve remarkable accuracy up to ±0.0005 inches or ±0.01mm. Compared to other technology, this accuracy is very high. This level of accuracy typically allows you to work with many complex shapes. However, a laser engraver and a laser cutter are two common types of laser machines.

Laser engraving and cutting are two popular types of shaping methods. When you decide to purchase between these two, many customers get confused. They often ask the difference between a laser engraver and a laser cutter. This article will clear all your confusion and help you make the right decision.

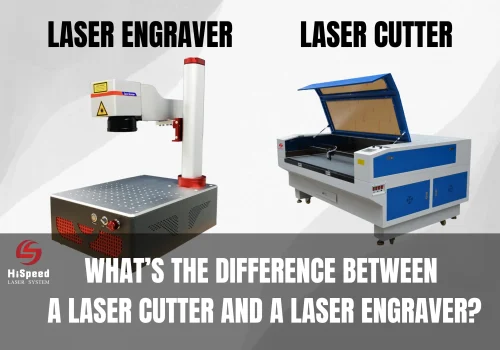

The Difference Between a Laser Engraver and a Laser Cutter

The use of laser engraver and cutter is all about precision and efficiency. Whether crafting jewelry or signage, the right laser machine makes all the difference. Investing in the right machine is also necessary to meet all your needs. Most people make mistakes not thinking about future projects. Therefore, the topic “laser cutter vs laser engraver” is crucial to understand before you invest in it.

To make the decision, you must first think about what you need. Do you want to carve detailed patterns onto metal, wood, or acrylic? Or are you looking to cut through thick sheets with smooth and clean edges? The wrong choice can cost you time, money, and effort.

Laser Cutter vs Laser Engraver: The Purpose

A laser engraver and a laser cutter have different jobs. Engraving is all about marking the surface of a material. It doesn’t cut through the material. It mainly creates or, more specifically, puts your design onto wood, glass, or leather. It’s typically great for personalization. For example, people love to engrave logos, serial numbers, barcodes, or decorative patterns.

Laser cutting, on the other hand, slices straight through materials. It works on all materials, including metal, acrylic, or wood. A laser cutting machine is typically meant to create precise and clean cuts. It is an excellent tool for building signage, prototypes, tools, spare parts, and more. The best thing about laser cutting machines is that they can create complex shapes, which is nearly impossible with traditional machines.

Laser Cutter vs Laser Engraver: Cutting Depth

One critical difference between a laser engraver and a laser cutter is the depth of the engraving. A laser engraving machine can typically engrave and reach a depth of 0.02 mm to 0.5mm, depending on the material type. It’s subtle but effective.

On the other hand, laser cutting can cut through materials. It can go deep—up to 25mm in some cases. The depth typically depends on the laser power and the material being cut. It is also crucial to note that the type of laser also matters. For example, fiber lasers work best on metals, while CO2 lasers work excellent on non-metals.

Laser Cutter vs Laser Engraver: Capacity and Power Levels

They both have different laser powers. A laser engraving machine usually has a power range of 20W to 500W, which is typically enough for marking and deep engraving.

On the other hand, laser cutters may have laser power from 40W up to 10,000W. Thin metal sheets typically need less power, while thick or hard metals like steel need high laser power. If you need heavy-duty cutting, pay special attention to the laser power.

Laser Cutter vs Laser Engraver: Use of Assist Gas

Not all laser machines need to assist with gas; they only need it for cutting. A laser engraving machine typically doesn’t require any assist gas. However, the assist gas helps remove melted material and cool it down to cut in laser cutting. Because of this, you can get cleaner edges, eventually preventing burning. Popular types of laser-cutting assist gases are CO2, nitrogen, argon, helium, oxygen, and compressed air.

Laser Cutter vs Laser Engraver: Design File Formats

The difference between a laser engraver and a laser cutter is not limited to their specifications. They also differ in many ways, one of which is software compatibility.

A laser engraving machine can typically work with both raster and vector images. You can work with SVG, DXF, and AI for vector images and PNG & JPG for raster images. However, a laser-cutting machine only accepts vector images. It strictly follows the vector paths.

Laser Cutter vs Laser Engraver: Price

Both laser machines also differ in their price ranges. A laser engraving machine is generally cheaper than a laser cutter. There are various reasons behind it. First, it uses a lower-powered laser source. Second, it doesn’t need advanced cooling systems and assist gases.

A beginner’s small laser engraving machine generally costs $500 to $1000, which is a very affordable option for most hobbyists. However, a professional machine may cost $5,000 to $10,000.

Conversely, a laser-cutting machine needs higher laser power. Consequently, it produces high heat. So, you need an advanced cooling system for this device. They generally cost from $2000 to $50,000. Therefore, if you need to cut thick materials with high accuracy, be ready to invest more.

Laser Cutter vs Laser Engraver: Size & Applications

Finally, size and applications also matter. A laser engraving machine is typically compact and fits on desktops. It is ideal for small—to medium-sized businesses. Besides, enthusiasts and hobbyists can significantly benefit from this device.

These laser-cutting machines are generally bigger than a laser engraving machine. You will be surprised that industrial laser cutters take up entire rooms. They’re used in manufacturing, signage, and large-scale production. Consider your workspace before buying a laser-cutting machine if space is an issue.

Summary

A laser engraving machine can only mark, etch or engrave. Since it doesn’t need high-power laser sources, it creates less heat. Thus, it doesn’t come with advanced cooling systems. This machine is compact and portable. Therefore, a laser engraving machine is cheaper than a laser cutting machine.

On the other hand, a laser cutting machine can cut through objects and slice them. It needs high-power laser sources, which results in high heat. Thus, these machines typically come with advanced cooling systems. A laser-cutting machine is more expensive than a laser engraving machine.

In today’s world, hybrid laser engravers can do marking, etching, engraving, and cutting. Based on your project needs, you can switch between these features. For more information, feel free to contact us.