LCleaning is a vital process in many industries worldwide. Different cleaning methods have already gained popularity in these industries. However, cleaning is necessary to ensure equipment and machinery’s safe and efficient functioning. These methods also maintain the appearance of surfaces. Laser cleaning is one of the most popular cleaning methods on this list.

The latest technology for industrial cleaning methods is the laser cleaning method. And with a short while, it gained the highest response from different industries worldwide. Why is laser cleaning so popular in industrial cleaning? We will find that answer in this article. First, this article will describe laser and other traditional cleaning methods separately. After that, we will justify the differences between each industrial cleaning technique. Finally, we will look at the industries they serve.

Laser cleaning

The laser cleaning method is a non-contact surface preparation technique. It uses high-power laser beams to remove contaminants from the material’s surface. However, it is a quick and efficient way of industrial cleaning. It is commonly used in the industries such as aerospace, electronics, and restoration. The last section of this article will briefly discuss their applications.

Laser cleaning uses a high-power laser beam to remove contaminants from a surface. The process fires a laser beam onto the surface of a target object. The particles on the surface absorb the high energy and break down the molecular bonds. Finally, it effectively removes the contaminants from the material’s surface.

You can adjust the process based on different types of contaminants and materials. Consecutively, you can optimize the laser cleaning process by adjusting the power, frequency, and laser pulse. On the other hand, depending on the type of application, you can also use different lasers.

Advantages of laser cleaning

Laser cleaning technology’s wide range of benefits makes it ideal for industrial cleanup. However, among the list of advantages, the following are the most common.

- Precision Cleaning: The laser cleaning method only removes contaminants from specific areas. It doesn’t affect the surrounding surfaces. As a result, it becomes ideal for precision cleaning. Notably, it has become popular in industries like electronics and aerospace.

- Non-abrasive: Laser cleaning is a non-abrasive cleaning method. As a result, it doesn’t cause any damage to the surface to be cleaned. Therefore, it becomes ideal for surfaces that traditional cleaning methods can easily damage.

- Environmentally Friendly: Laser ablation does not require any chemicals or solvents. As a result, it is an environmentally friendly cleaning method. Moreover, it is a dry process that produces no waste or emissions.

- No chemicals or solvents required: The laser cleaning method does not require any chemicals or solvents. As a result, it is a safer cleaning method for workers and the environment. In addition, it also reduces the costs associated with disposing of hazardous waste.

- Fast and Reliable: Laser cleaning is the quickest and most reliable cleaning technology. It is a dry process and doesn’t require any drying time.

Limitations of laser cleaning

Although the laser cleaning method has many benefits, it also has some limitations. The following are the most common disadvantages of using laser cleaners.

- Limited effectiveness on certain materials: Laser ablation is effective for many surfaces. But it may not work as well on certain materials. Dark or reflective surfaces are not ideal for laser cleaning.

- Upfront cost: The initial cost of purchasing a laser cleaning machine is relatively high. However, it is an environmentally friendly and effective cleaning device. As a result, it is a positive long-term investment. Over time, the cost savings from reduced chemical use and maintenance may offset the initial cost.

Traditional Cleaning Methods

Traditional cleaning methods refer to the use of conventional cleaning techniques and equipment. These methods have been popular for many years to clean surfaces. They help in cleaning dirt, rust, grime, and other contaminants. However, traditional cleaning methods typically use water, mechanical equipment, ice, sand, and chemical. They might require manual scrubbing or rubbing to remove dirt and stains from the surface.

Traditional cleaning methods can be effective. But they may require significant time, labor, and resources to achieve the desired result. In addition, some cleaning methods may use harsh chemicals and solvents, which are harmful to the environment.

Types of traditional cleaning methods

Traditional cleaning methods come in different types. Each of these types has its advantages and disadvantages. Here are some common types of conventional cleaning methods:

- Mechanical cleaning: This method uses mechanical force to remove contaminants from the surface. It may include scrubbing with brushes, sponges, or pads. It may also involve using machines like pressure washers, carpet cleaners, or floor polishers. However, mechanical cleaning can be an effective solution. But it may require a lot of labor and may not be a versatile option.

- Chemical Cleaning: This traditional method uses various cleaning agents. These cleaning agents include detergents, solvents, and acids. They break down and remove dirt, grime, and other contaminants from the surface. This method is also an effective solution. But it may be harmful to the environment and human health. In addition, some toxic chemicals may cause respiratory problems or skin irritation.

- Water blasting: This method uses high-pressure water to remove contaminants. This method is also effective for cleaning outdoor surfaces like buildings, sidewalks, and parking lots. But water blasting may not be suitable for indoor surface or delicate materials cleaning.

- Abrasion blasting: This method uses abrasive materials to remove contaminants. The abrasive materials may include sand, walnut shells, or glass beads. However, this method is also an effective solution. But it may damage the surface of the materials.

In the above discussion, we have already covered each type of traditional cleaning method’s definition. We have also mentioned the advantages and disadvantages at the end of each paragraph. However, conventional cleaning methods can be effective. But they still have some limitations regarding quality cleaning.

Laser cleaning vs. Traditional cleaning methods

The type of cleaning method depends on the specific cleaning requirements of your project. It also involves the kind of surface being cleaned. We know that laser cleaning is the most effective solution. But still, in some cases, traditional cleaning methods may be more suitable for specific surfaces. However, it is up to you to weigh the pros and cons of each technique and make a decision.

- Cleaning effectiveness: Laser cleaning is highly effective at removing contaminants. It doesn’t damage the underlying surface. However, there’s a limitation in the cleaning effectiveness on certain surfaces. On the other hand, the efficacy of traditional cleaning methods depends on the type of surface to be cleaned. Mechanical cleaning may be suitable for removing dirt or grime. Besides, chemical cleaning may be ideal for removing tough stains.

- Cost-effectiveness: The initial cost of laser cleaners is higher than traditional cleaning machines.

- Environmental impact: The laser ablation method is an entirely environmentally friendly solution. It doesn’t create any hazardous waste that may harm the environment and human health. Traditional cleaning methods such as chemical cleaning and abrasion blasting create dangerous waste. This waste may be harmful to the environment and human health.

- Safety considerations: Laser cleaning can be dangerous if you don’t take the necessary steps for safety. Professional operators must be considered in this case. Traditional cleaning may also pose safety risks. Especially in the case of chemical cleaning and abrasive blasting, there are a lot of safety concerns that you should consider.

Summary Table

| Comparison

Factors |

Laser Cleaning | Chemical Cleaning | Mechanical Cleaning | Water Blasting | Abrasive Blasting |

| Mechanism | High-power lasers ablate or vaporize the contaminants | Performs chemical reactions to dissolve or break down the contaminants | Mechanical force physically removes the contaminants | High-pressure water dislodges and removes the contaminants | Abrasive materials physically remove the contaminants |

| Contact | Non-contact | Contact | Also Contact | Contact | Also Contact |

| Precision | High | Low | Low | Also Low | Low |

| Cost | High | Low-medium | Low-medium | Medium | Medium-High |

| Environmental Impact | Low | High | Low | Medium | High |

| Safety | High | Low-medium | Medium | Low – Medium | Medium |

| Applications | Precision cleaning of delicate surfaces | General cleaning | Cleaning and maintenance of industrial equipment | Hard-to-reach areas and sensitive surfaces | Surface preparation, heavy-duty cleaning |

Applications of Laser Cleaning and Traditional Cleaning Methods

The type of cleaning method depends on the specific application of your project. We know that each industrial cleaning method has unique advantages and disadvantages. As a result, these unique advantages make these methods suitable for particular cleaning needs. However, in the following, we will discuss some of the most applications of these cleaning methods.

Industries that use laser cleaning:

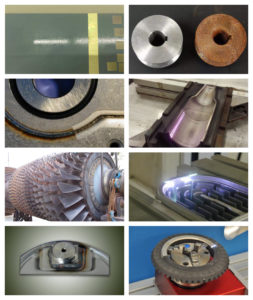

- Aerospace: Laser cleaning is prevalent in removing contaminants from aircraft components. Turbine blades and engine parts are the most famous examples.

- Automotive: Laser ablation is also prevalent in removing paint and rust from automotive parts.

- Electronics: Laser cleaning is beneficial for cleaning delicate electronic components.

- Restoration: laser ablation helps in restoring historical artifacts. These artifacts may include sculptures, monuments, and buildings.

Industries that use traditional cleaning methods:

- Health and Care: Chemical cleaning is especially prevalent in this industry. This cleaning method helps to sanitize medical equipment and facilities.

- Food processing industries: Water blasting is prevalent in cleaning food processing equipment.

- Manufacturing industries: Sandblasting or shot blasting is prevalent in this industry. These methods are used to prepare surfaces for painting or coating.

Final Thought

In conclusion, laser and traditional cleaning methods have unique advantages and disadvantages. Laser cleaning offers a precise, non-abrasive, environmentally friendly, and chemical-free process. It is indeed an effective solution for cleaning in industrial applications.

When choosing a cleaning method, it is essential to consider some factors. Consequently, these factors may include the type of surface, the required level of cleanliness, the environmental impact, and the budget. Above all, laser cleaning is expected to continue to improve. In the future, laser cleaning technology will offer more practical and cost-effective solutions. “Why Laser Cleaning is the Future of Surface Preparation: Top 5 Reasons” explains more about the benefits of laser cleaning.

HiSpeed Laser provides a good collection of laser cleaners. These laser cleaning machines are highly durable and reliable. However, contact our customer support team if you have any questions about laser cleaning and these machines.