Laser engraving from the comfort of your own home or workplace is now easier and cheaper than ever. Laser engraving was formerly exclusively the domain of industrial manufacturers, but it is now a widespread and widely used tool for small enterprises, product designers, makers, and hobbyists.

Whether you are a DIY enthusiast or work in the engineering business, you have most likely heard of this 3D laser printer that cuts your equipment with extreme accuracy.

Continue reading if you want to learn more about these fascinating devices! This page will explain what an engraving machine is, how it works, and what it can cut.

What is a laser engraving machine for metal?

Laser engraving is a method to create lasting, deep markings by vaporizing materials into fumes. The laser beam operates like a chisel, incising markings by eroding layers from the material’s surface. The laser delivers large amounts of energy to specific regions in order to achieve the high heat necessary for vaporization.

A laser engraving machine is a machine used to apply this technique of engraving on nearly any surface. Laser devices can also generate legible markings on practically any metal, wood, leather, or other material in a timely and effective manner.

There is laser engraving equipment designed specifically for metal. They are commonly used to engrave many sorts of metal surfaces. Aluminum, anodized aluminum, steel, stainless steel, magnesium, lead, and zinc are a few examples.

How much does a decent laser engraving machine cost?

Laser engravers are utilized for precise work that other sorts of machinery cannot perform. As a result, they employ a laser beam to mark, cut, or, as the name implies, engrave an image on the material of your choice. They are frequently used to engrave into materials that are too fragile for conventional cutters or saws. These devices can carve wood, acrylic, soft metal, rubber, and other materials with incredible precision.

There are several materials that may be utilized in those devices, but you must exercise caution. Especially whether you are purchasing one for yourself or your business! These machines are more exact, but they function better on the materials they are designed for, and the cost varies according to the demand.

In general, 3d laser engraving machines are expensive pieces of machinery that businesses acquire for particular jobs. And, although some models cost as little as $200, top-of-the-line versions can cost up to the $1000s and are available with a variety of financing options.

What type of laser engraving machine should I buy?

As mentioned, these 3d laser engraving machines, though precise, work better with the materials they are meant to. Some can engrave glass with massive detail, and some might break it. So you need to be careful to not have any regrets in the future.

To determine the sort of laser engraving equipment to use, consider the following: “What materials will I be engraving?” Before deciding on a laser engraver, consider the various projects you will be working on as well as the materials you will be engraving.

Let’s understand what each material needs.

Metal:

Key chains, jewelry, presents, name tags, and a variety of other applications can benefit from laser engraving on metal. The laser engraving machine for metal is accurate and may be done to an incredibly fine degree. Fiber Laser Marking Machine; Fly Laser Marking Machine; Mini Portable Laser Engraver may be used to etch many different types of metal.

Paper:

Cutting paper with a best laser engraving machine is a great way to put one to use. It may be used to make invitations, artwork, and other unique items. Custom cuts and designs may be made with a laser engraver. Paper may be engraved using both the CO2 Laser Engraving Machine and the CO2 Laser Cutting Machine.

Rubber and Plastic:

The advantage of utilizing laser engravers instead of traditional engravers is that you can carve plastic extremely precisely without worrying about melting it. If you want to engrave on plastic or rubber, the CO2 Laser Marking Machine and CO2 Laser Cutting Machine are the ideal options.

Glass:

Because glass and crystal are so delicate, they cannot be etched using a typical engraver. But you can get permanent, accurate engravings using a glass laser engraving machine, which is ideal for medals, trophies, or even wine glasses. The CO2 Laser Marking Machine and CO2 Laser Cutting Machine are ideal for engraving most non-metallic surfaces, including glass.

See? For each material, there is a perfect glass laser engraving machine for it. You can find all the machines mentioned in the section above on our products session up on this page.

What materials can I cut with lasers?

The adaptability of laser cutting is one of the reasons it is so popular. Laser cutters can cut a broad range of materials, including paper, wood, cork, acrylic, and foam, as well as various metals. And any materials that are often used in industrial processes. Steel, aluminum, stainless steel, and non-ferrous metal sheets, as well as non-metal materials such as plastics, glass, wood, or ceramics, may all be cut safely and accurately with a laser.

But did you know that when it comes to laser cutting, there are safe and risky materials? Because many plastics are hazardous to cut for spreading fumes or catching fire, it is critical to know which type you want to use.

So be careful with the materials ahead:

- PVC: when cut, emits pure chlorine gas;

- Thick Polycarbonate: can go from just discoloring to even catching on fire;

- Fiberglass: emits dangerous fumes;

- PolyStyrene or PolyPropylene Foam: when hit with the laser, it will catch on fire;

- Glass: you can etch it, but not cut it.

Just make sure to consult your provider, or even the instructional manual to see what your new machine can and cannot cut. But, as stated before, basically anything from wood to cardboard, paper, or metal can be cut and marked with the right laser engraving machine.

Best laser engraving machines

Laser engraving has never been just the domain of industrial manufacturers; it is now a widespread and widely used tool for small enterprises, product designers, crafters, and hobbyists.

In some circumstances, a laser engraver may prove to be the most advantageous technology for your requirements. So, before you go for your cash, you might want to take a walk through our list of the top 10 laser engravers to discover which unit is ideal for you.

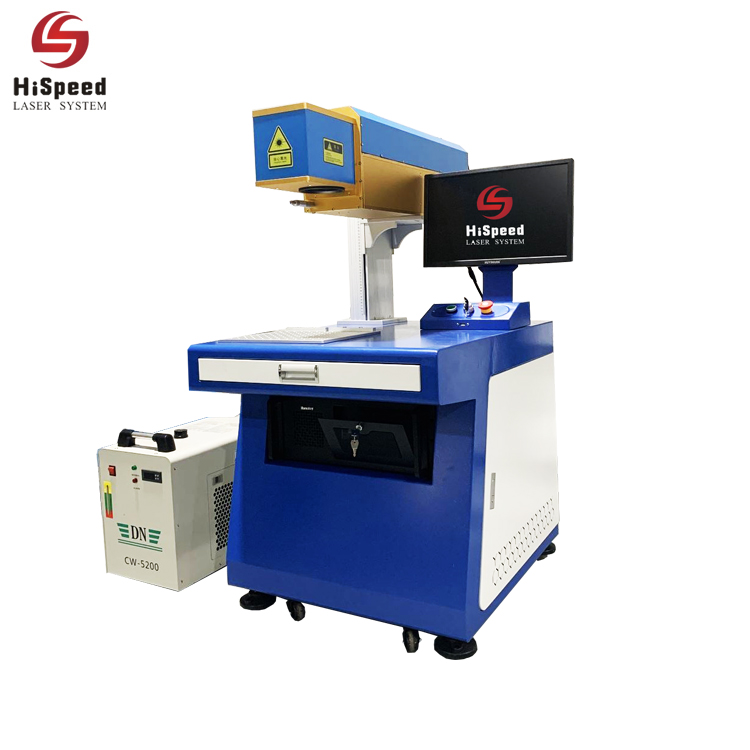

Fiber laser marking machine

This equipment is also known as a fiber laser engraving machine or a fiber laser marker. A fiber laser marker is a form of CNC laser marking device that uses a fiber laser beam to leave a permanent mark on the surface of a variety of metal and nonmetal objects.

It is also extensively utilized in industrial manufacture, school education, home business, and other fields. If you want quality and precision, Hispeed will provide you with high-quality fiber laser markers as well as skilled customer service to fulfill your needs.

To communicate information, the fiber laser manufacturing machine generates contrast between materials or work-pieces. The fiber laser’s color shift is a normal part of its operation. In this situation, the laser beam strikes the surface of the specified materials, causing the contrast to shift. As a result, the design’s colors are determined by the frequency of the laser beam emitted by the fiber marking laser.

UV Laser Marking Machine

UV laser marking machines are mostly used for fine marking on glass, plastic (PP, PVC, PET, PE, HDPE, ABS), jade, ceramics, and a variety of other materials. UV laser markers outperform previous procedures, compensating for flaws such as poor processing precision and difficult sketching in the past. Hispeed will provide you with high-quality UV laser marking equipment with power options of 3W, 5W, 8W, and 10W as well as a customized laser marking process area.

It can generate an ultraviolet laser beam to etch the materials’ surfaces. UV Laser engraver and UV Laser marker are both terms that can be used to describe the same device. The diode is a semiconductor device that we are all familiar with. This ultraviolet beam is produced by a UV laser diode based on Gallium Nitride, which emits near UV laser wavelengths.

CO2 Laser Cutting Machine

The CO2 laser cutter is a CNC laser cutting machine that utilizes a CO2 laser to cut wood, plywood, fabric, plastic, leather, paper, and thin metals. It is extensively used in industrial production applications, school education, and even home business.

CO2 laser cutting machines cut items by using CO2 and other gas particles as a laser medium. This laser cutting machine can cut through any solid material, including acrylic, wood, paper, metals, plastics, and other components. And the more powerful it is, the more easily it can cut through thicker materials. Hispeed offers the most competitive CO2 laser cutting machine pricing.

Fly Laser Marking Machine

The flying laser marking machine is ideal for batch production and high marking precision in the food printing, wine sector, mineral water, daily cosmetics, and other types of production lines. Flying laser engraving cutting machine offers a high production efficiency and consistent quality.

Hispeed carries a high-quality laser engraving machine for metal. Our equipment uses the most sophisticated technology available, emitting a high-quality laser beam.

Mini Portable Laser Engraver

Portable laser engraving machines are sometimes referred to as mini portable laser engraving machines, handheld laser engravers, and portable laser engravers. Because of its compact size, it is extremely user-friendly. A portable laser engraver may be used as both a standard marking machine and with a handheld laser head.

You may mark any section of huge machinery parts and components with the aid of a portable laser engraver. It does an excellent job of resolving the problem of huge component marking.

At HighSpeed, you can find a variety of models to choose from, and see what fits the best for you. Whichever is the best option for you, we will make sure it arrives at its best, so you can have high-quality equipment and no worries at all.

Precision Laser Cutting Machine

This is a unique cutting tool that was created by combining laser technology with numerical control technology. It has the following features: steady laser power, good beam pattern, high peak power, cheap cost, safety, stability, and simplicity of operation.

This machine can meet expectations thanks to its high processing efficiency and stable operation. The cutting seam quality is excellent, the distortion is minimal, and the look is smooth and lovely. We promise a mature processing technique that is appropriate for all types of graphics processing. With Hispeed, you can rely on a team of professionals that are ready to assist you with everything.

Laser Cleaning Machine

A laser cleaning machine uses irradiation to remove impurities and contaminants from a material’s surface, such as paint removal, oxide removal, rust removal, and so on. Laser cleaning machines are commonly used in the cleaning of metal materials as well as coated surfaces such as stainless steel, carbon steel, and coated items.

A laser derusting machine is a high-tech surface cleaning tool from a new generation. It’s quite simple to set up and use. There are no chemical reagents, no media, no dust, and no water cleaning, autofocus, suitability for crank surface cleaning, high surface cleanliness, and other benefits.

Surface resin, oil, filth, dirt, rust, coating, coating, paint, and other materials can be removed with laser cleaning equipment.

Hispeed laser cleaning equipment can meet all of your requirements due to its high beam quality, built-in energy-saving technology, and extended service life.

Conclusion

By vaporizing materials, laser engraving is an innovative approach for creating long-lasting, deep imprints. The laser beam acts like a chisel, incising patterns by removing layers from the material’s surface. Laser engraving devices can cut and etch into a variety of materials, from wood to metal!

This process allows anyone, including you, to enjoy crafting jewelry, art, or simply decorations and adjustments for objects. Allow your imagination to run wild in this new field; the possibilities are unlimited!

When it comes to engraving machines, there is no right or wrong answer. Check out our website and all of the machines available for any of your needs to make sure you get the most out of your equipment.