CO2 laser cutting machine is a device that uses CO2 laser as a cutting tool. It has been widely used in many fields such as advertisement, construction, automotive, electronics, medical, cloth, and other industries. This article will introduce the principle, advantages, and application industries of CO2 laser cutting machine.

Principle of CO2 laser cutting machine

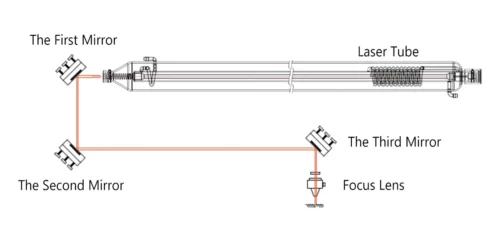

A CO2 laser is a gas discharge laser that produces a continuous or pulsed wave with a wavelength of 10.6 micrometers (in the infrared region) by using transitions between the vibrational and rotational energy levels of carbon dioxide molecules. It consists of three parts: a discharge tube, a reflector, and an output mirror.

The discharge tube is filled with a gas mixture of carbon dioxide, nitrogen, and helium. When a high-voltage DC power supply is applied, a stable and uniform discharge phenomenon is generated in the discharge tube. The discharge ionizes a large number of molecules in the gas mixture, forming a plasma. There are a large number of carbon dioxide molecules in different energy states in the plasma. When a carbon dioxide molecule in a high-energy state (vibration-rotation energy level) collides with a carbon dioxide molecule in a low-energy state (ground state), stimulated emission occurs, that is, the high-energy molecule releases photons of a certain wavelength to the low-energy molecule. These photons reflect back and forth in the discharge tube, forming laser oscillation. A portion of these photons is output through the output mirror, forming a laser beam.

The CO2 laser cutting machine focuses the output laser beam through a focusing lens or mirror onto the surface of the material, forming a small-diameter, high-energy-density spot. Near the spot, the material is rapidly heated to the melting or vaporization temperature and is blown away by high-pressure gas (such as oxygen, nitrogen, or air), thereby achieving cutting or engraving of the material.

Advantages of CO2 laser cutting machine

High precision: The CO2 laser cutting machine can achieve high-precision cutting without sacrificing material quality, and the cutting edge is smooth and burr-free without the need for subsequent processing.

Speed: The CO2 laser cutting machine has a high cutting speed and can quickly complete a large number of cutting tasks.

High efficiency: The CO2 laser cutting machine uses numerical control technology and can complete complex cutting tasks in a short time, improving production efficiency.

Environmentally friendly: The CO2 laser cutting machine uses a non-contact cutting method, which does not produce cutting waste and does not cause pollution.

Fast cutting speed: Due to the high electrical-optical conversion efficiency and stability of CO2 lasers, they can produce a strong and continuous laser beam and have a faster cutting speed than other types of lasers at the same power.

Good cutting quality: The CO2 laser has a longer wavelength and better penetration and absorption on materials, which can achieve smooth, neat, burr-free, and deformation-free cutting effects. Moreover, due to the high beam quality and focusing ability of CO2 lasers, they can achieve smaller cutting seam width and higher cutting accuracy.

Application Industries of CO2 Laser Cutting Machine

Metal processing industry: The high power CO2 laser cutting machine can cut various metal materials, such as steel, aluminum, copper, iron, etc. It can be used to manufacture car parts, aircraft parts, building structures, etc.

Construction industry: The CO2 laser cutting machine can cut building materials, such as glass, ceramics, stone, etc. It can be used to make building appearance decorations, doors and windows, wall panels, etc.

Automotive industry: The CO2 laser cutting machine can be used for the manufacture of car parts, such as car bodies, chassis, interiors, etc. It can cut various shapes of materials, such as steel plates, aluminum plates, plastics, etc.

Electronics industry: Manufacture of electronic components, such as circuit boards, wires, electronic components, etc. The CO2 laser cutting machine can cut very small materials and achieve high-precision cutting.

Medical industry: The CO2 laser cutting machine can be used for the manufacture of medical instruments and implants, such as surgical instruments, artificial joints, etc. It can cut various materials with high precision and cleanliness.

Packaging industry: CO2 laser cutting machines are used in the packaging industry to cut and engrave various packaging materials, such as paperboard, cardboard, and plastic films.

Advertising industry: CO2 laser cutting machines are used to cut and engrave various advertising materials, such as acrylic letters, logos, and signs.

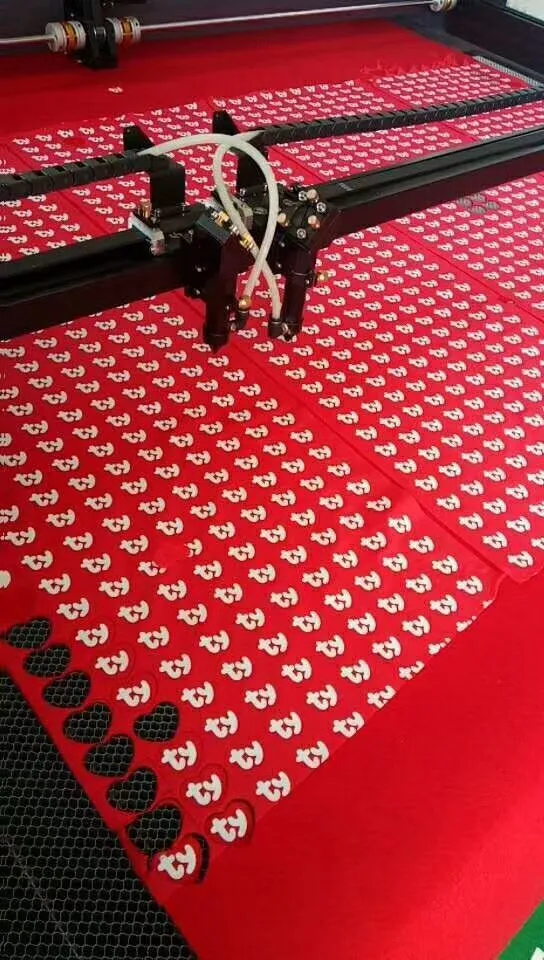

Textile industry: CO2 laser cutting machines are used in the textile industry to cut and engrave various textiles, such as fabrics, leather, and synthetic materials.

Conclusion

CO2 laser cutting machines are widely used in various industries due to their advantages in cutting speed, cutting quality, and cutting thickness. They can cut various materials, such as metals, plastics, textiles, and non-metallic materials. CO2 laser cutting machines have high precision, high efficiency, and low maintenance costs, making them an ideal choice for many industries.