You may be familiar with laser marking machines. How do they work, and what are the different types? But when it comes to fly laser marking, many of us get confused. In this “fly marking vs static laser marking” guide, we will try to compare these two technologies. In which situation does this technology suit you the most?

Laser marking is one of the most popular products in the modern world. It provides the most accurate results of any marking tool. When it comes to industrial manufacturing, we often hear the term “on-the-fly” laser marking. This machine generally uses a conveyor belt on which the object flies toward the laser gun. While flying on the conveyor belt, the laser gun quickly marks the object. Laser marking can be of various types; you will learn more about it in the next section.

Choosing the right option sometimes becomes very hard when there are a lot of options to choose from. Understanding their differences helps a lot here. There are a few things to know when deciding between the two main options for laser marking. You will learn more about them in the later section of the article.

However, if you need speed, fly marking may be the solution. If precision is required, static marking may be the best solution. Knowing your needs may assist you in considering these opportunities. Remember that making the proper decision always ensures a simpler and more productive job.

What is Static Laser Marking Compared to Fly Marking?

Static marking is the laser marking process you see in general. In this method, the object you laser mark stays still. Hence the term “static”. However, the laser moves along the designated area to create the desired mark. Static laser marking machines are widely used for highly detailed markings.

People prefer static laser marking in a wide range of industries. It is used to label designs, logos, texts, and even pictures of any given material.

How Does a Static Laser Marking Machine Look Like?

A standard laser marking machine has three main machine parts. (1) A laser source creates lasers. (2) A laser scanner head directs that laser on the object’s surface. (3) The worktable is where you will put your object. However, a standard laser marking machine also comes with a control system. This device is necessary for managing the laser’s operation.

How Does a Static Laser Marking Machine Work?

This procedure is simple but quite effective. It begins with placing the piece on a worktable. You must properly orient the object so that the laser marks it in the correct location. Then, you must focus on modifying the design and laser settings.

Depending on the type of laser that is being used, the laser beam marks the surface of the object irreversibly. The type of marks generated could also depend on the type of materials and laser sources being used. There are six primary types of laser marking: ablation, engraving, foaming, carbonizing, coloring, and annealing.

Applications of Static Laser Marking

Static laser marking is a prevalent option that does not require faster production. It is common in custom manufacturing, jewelry, automotive, small businesses, and the art industry. You may also find its uses when making lots of medical items.

Benefits of Static Laser Marking Machine

(1) The static laser marking machine offers more precision than the flying laser marking machine. It can create details and even pictures of higher complexity.

(2) This machine is easy to use, but it requires less setup than fly marking.

(3) The static laser marking machine allows to do multiple passes on a single object. Because of this, you can get high-contrast results. Overall, you can get quality markings.

(4) Static laser marking machines are comparatively cheaper than laser fly marking machines. There’s no need to set up a moving system, which cuts down the initial cost.

(5) Static laser marking works great for small businesses, do-it-yourself projects, and making unique items.

Limitations of Static Marking

The only limitation of this machine is limited throughput. You can only mark one object at a time. Static laser marking is not preferred for large productions or bulk orders. The manual manipulation of the objects usually slows down the process. Because of this, you may be able to create four times fewer products than fly marking systems.

What is Laser Fly Marking Compared to Static Marking?

If you consider the object placement, fly marking is the opposite. As the name implies, the object flies on a conveyor belt during this process. So, in flying laser marking, the laser machine remains still while the object moves in a constant motion.

This method is especially useful in industries that rely on high-speed production lines. For example, in packaging, you will need to mark thousands or millions of products at a time. Manually changing objects is time-consuming and requires labor. Fly marking is the best solution here.

Typical Structure of a Fly Laser Marking Machine

The structure of a fly laser marking machine differs from that of a static one. In addition to static laser marking, this machine has one additional component: a conveyor system.

The conveyor in fly laser marking systems plays a crucial role. It typically helps you mark products automatically. The conveyor system generally comes with a moving belt with an asynchronous motor. You can control the speed of the motor based on the accuracy and speed of your laser marking.

How Does it Work?

Once again, fly laser marking works differently than static marking. In static marking, the laser marks stationary objects. However, in a fly marking system, the object moves continuously through the conveyor system. Because of this, fly marking is also sometimes renowned as conveyor marking or automatic marking.

The most crucial work in fly marking is synchronizing the timing of the beam. At the right time, you must be able to mark the right location on the surface of the object. Therefore, you must adjust the position of the sensor. Also, you must know the distance from the laser gun to the object.

Based on this information, you can adjust your laser settings. And perform a test operation before the actual operation. The laser marking will not operate until the sensor detects the objects. In some modern laser marking systems, many feature detection techniques are used to detect objects.

Once laser marked, the products can either move along the conveyor system or you can manually take them to the packaging. In most cases, fly marking is employed on automatic systems.

Applications of Flying Laser Marking Machine

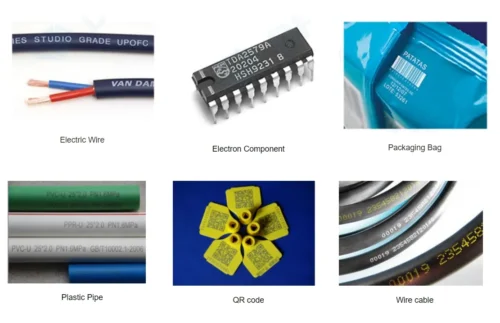

Fly laser marking is mostly used for high-production orders. Therefore, it may be found in the food and beverage, electronics, manufacturing, and metal industries. It can also be used in small—to medium-sized businesses to mark pipes, electric wires, or even measuring tape.

Benefits of Fly laser printer

- Fly laser marking eliminates the stop-start process. This machine is ideal for high-volume production.

- It is capable of marking thousands of items in less time compared to static marking.

- Fly marking is highly flexible, easy to integrate with automated systems, and accommodates various object shapes and sizes.

- This machine incredibly reduces the cost per part. Because of this, you can get quick returns from investing in fly marking systems.

Limitations of Fly Marking

- Fly laser marking machines cannot offer as precise results as static marking systems. You can mostly create texts, codes, and numbers for the product.

- The synchronization step requires expertise.

- The addition of a conveyor system typically adds to the initial cost.

Fly Marking vs Static Laser Marking: Which One is Right for Your Project?

Before you decide between fly and static marking, you should look at the intended job. In many fields, both methods are used a lot. When you spend, though, picking the right machine becomes important.

Flying Marking VS Static Laser Marking: Speed and Precision

Fly marking is popular because it’s fast and efficient. But when it comes to precision and detail marking, static marking is the one you should look for.

You can use flying marking to mark thousands of items at a time. However, the static laser needs manual labor and takes time when changing objects. It only makes the process slower but also requires extra labor. Therefore, fly marking is ideal for high production volume.

Fly Marking VS Static Laser Marking: Integration with Other Systems

A static laser marking machine is made for single-purpose work. It can not integrate with other systems, and the process might be a little complex if you want to.

Conversely, fly marking is designed to integrate with production lines. Its features can easily blend into various systems.

Flying Marking VS Static Laser Marking: Cost Constraints

When considering the cost, you can think about two main factors. (1) The initial cost that you need when you first invest in a machine. (2) The operating cost, which includes repair and maintenance.

Both flying marking and static marking need less repair and maintenance. However, flying marking requires an extra cost for the conveyor system. However, if you consider the production cost, fly marking produces less cost per part. Because of this, investing in a fly laser marking machine is typically a productive decision.

Fly Marking VS Static Laser Marking: Versatility

Fly marking and static marking can be used in a lot of different ways. They are very good at working with a wide range of products and tasks. If this is the case, fly marking might be missing a few things.

Fly Marking VS Static Laser Marking: Expertise

Finally, the ease of use of the devices should be considered. Fly marking requires more technical knowledge of how to synchronize the sensor setup. Also, exact positioning is critical when working with tubular items like wire, tubes, or tapes. Make sure your team has the right skills for the job.

Summary

In this article, we mainly discussed the suitability of two popular types of laser marking machines. We went through the benefits and limitations of each type.

Static marking is precise but slower, but it is very suitable for small-scale production. On the other hand, fly-making offers the best performance in high-speed production lines. Because of this, it is perfect for businesses that need to make a lot of things. Fly marking is quick, but it can’t give you very accurate results.

You can now relate that both types have unique benefits and applications. One type has limitations, while the other has advantages. Therefore, choosing the right type for your project is crucial.

If you are interested in high-quality laser marking solutions, feel free to contact our customer support team.