Laser engraving is a top trend and a great side business. There are several types of laser engravers available in the market. Selecting the best fiber laser engraver is crucial for business success.

This guide is all about selecting the best fiber laser engraver for metal. We will discuss different variants of laser engravers. Why they are helpful to you and how you can buy your first laser engraver for metal.

Different Options in Fiber Laser Engravers

The fiber laser engraver focuses a laser beam on the material surface. As the laser moves on a given path, it vaporizes the metal to develop an engraved design. These machines are compact, efficient, safe, and a cost-effective solution.

So, if you are a small business that provides engraving services, a fiber laser marker is your best bet. The same is true for a manufacturing company that needs to engrave its brand on its products.

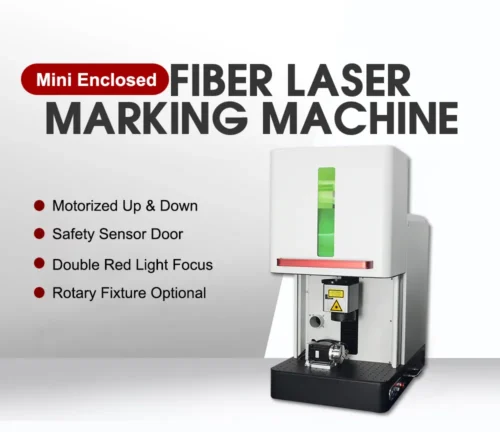

There are several variants of fiber laser engravers. Each variant has its distinctive features. There is an Enclosed Fiber Laser Marking Machine. It encloses the workpiece before engraving, eliminating any mishap that might occur due to negligence.

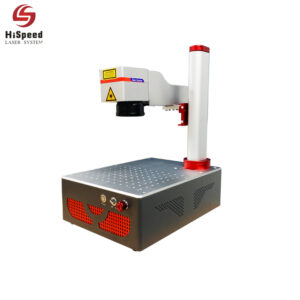

Another variant is the Desktop Fiber Laser Engraving Machine. It is a simple and cost-effective solution. These machines are available with multi-laser heads to process more than one workpiece.

There is another variant called the Automated Six Station Fiber Laser Marking Machine. It has a rotating table that can mount six workpieces. This machine reduces the time, effort, and cost of the engraving.

From all the options you can have, it can be hard to select the one that is best for your business. So, we have developed a complete guide for you to follow and filter the best machine for you.

Choosing the Best Fiber Laser Engraver

Choosing the best fiber laser engraver that fulfills all your business needs is crucial. It influences your business abilities and profitability. So, it decides the business growth and success. Following are some factors that you need to consider during the selection process.

1. Your Business Requirements

The first thing you need to consider is your business requirements. You should know the answers to some questions here. What are the services of your laser engraving business? What product do you engrave? What is the size of the product you need to engrave? What type of materials do you need to process? What is the profit margin?

It will help you know what you need from your fiber laser marker machine. These answers will also help you in further stages of machine selection.

Keep in mind that having a proper business understanding is very important here. Decisions made in this section will influence your machine selection. So, know your industry and how it works, its limitations, and potential to expand business.

2. Considering the Machine Table Size

The best fiber laser engraver for metal uses the machine table to place and hold the product. Usually, the product is first placed and gripped on the machine table, and then the engraving process can start.

So, you must know the maximum product size you need to engrave. Based on this, you can filter all the available machines that can process that maximum product size.

Selecting a machine like this will enable you to engrave all products within the maximum dimensions limit.

3. Machine Engraving Area

The machine engraving area, also known as the machine working area, is the area limit a machine can engrave. It is different from the machine table size.

The table size is the machine’s ability to hold the workpiece, whereas the working area is the cross-section area engraved. The working area is always less than the table size. It depends on the laser field of view.

The fiber laser marker works by focusing a laser beam on metal. To engrave the metal laser moved as per the instructions given by the machine computer.

There is a limit up to which the laser can move, called the field of view of the laser.

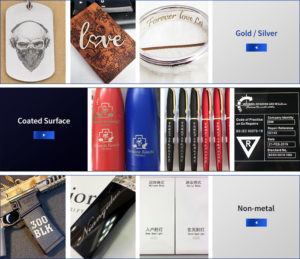

4. Machine Material Compatibility

There are several laser engraving machines in the market. Some of the common types are laser engravers for metal. Laser machines that are developed for engraving metal only. Further classified by metal types, such as soft metals (aluminum, copper) and hard metals (steel, titanium).

Other than metal engravers, there are best laser engravers for plastic materials. There are also fiber laser engravers that can process both metallic and plastic materials.

Selecting the best fiber laser marker based on material compatibility is a good idea. It will define your business domain and enable you to excel in one direction.

5. Machine Laser Source

The fiber laser engraver uses a fiber tube made from different elements. A fiber tube can be made of a single or a mixture of elements. Each element or a mixture of elements can produce a laser beam of a specific wavelength.

So, based on your business and industry requirements. You can filter the specific best fiber laser engraver for metal based on the fiber laser source element.

Some common types of fiber laser source elements are as follows.

- Fiber laser sources from Ytterbium-doped fiber can create a laser beam with a wavelength of 1065 nm. It is perfect for working with metals. You can use these lasers for marking and cleaning metal surfaces.

- Fiber laser sources from Thulium-doped fiber can create a laser beam with a wavelength of 1940 nm. This specific best laser engraver is helpful in medical fields and for marking plastic materials.

- Fiber laser sources from Erbium-doped fiber can create a laser beam with a wavelength of 1550 nm. This specific laser engraver is helpful in the telecommunications field. It provides high-speed internet and voice-over IP services.

Select the fiber laser source element best for your industry and diversify your business.

Another important factor related to the laser beam is the type of beam the machine produces. There are two basic types of beams. The first is a continuous beam, and the second is a pulsed beam.

Plused-type beams have an energy peak point in a pulsating manner. Due to this, they are considered best for laser engraving projects.

6. Machine Laser Parameters

Machine laser power is the laser beam’s ability to develop required engraving. A laser beam with more power can do engraving faster and better.

More power means the laser beam can melt and vaporize the material quickly and better. It can produce deep grooves and can develop big fonts.

Selecting the best fiber laser engraver means selecting a laser engraver for metal with sufficient laser power. A machine with lesser laser power will not engrave materials faster.

Other factors of laser machines include spot size, beam diameter, beam focal length, and beam quality. Select a machine based on the higher laser power and better beam quality.

Similarly, find the machine with the spot size and laser beam diameter as per industry and business requirements.

Besides the power, other things affect how long it takes to engrave. These include:

- The font used for text and serial numbers.

- The size of the area being engraved.

- The material being engraved (for instance, aluminum is easier to engrave than steel).

- The background color of barcodes, data matrix codes, and QR codes (for example, a light background improves contrast but takes more time).

7. Machine Parameters

It is time to consider different machine parameters that concern your business. The fiber laser marker machines use a computer system to take CAD files of patterns to be engraved. So, the selected machine should have a powerful computer system installed.

In computers, dedicated software enables computers to read CAD files. They convert them into machine operational instructions. The machine software should be compatible with most CAD file formats and easy to use.

Other than this, the best laser engraver machine scans the workpiece before engraving. This scanning speed has to be fast to save time and reduce running costs.

Some fiber laser engravers also have an autofocusing feature. Autofocus technology utilizes vision systems to identify changes in the positioning of parts. It then automatically adjusts the laser focus to maintain optimal engraving conditions.

This technology is essential when parts cannot be precisely positioned. This usually happens when various part models are used, or when working with highly curved surfaces.

Machine running cost is also the main factor included in this section. It depends on a lot of machine laser power and other machine electronics.

8. Maintenance and Safety

After considering all the machine related factors, it is important to consider the machine maintenance. General maintenance includes keeping the machine clean by removing busts and debris.

Schedule maintenance includes checking the machine electronics connections and wires. It also involves checking the machine laser head and table for any damage during operation. Laser heads can get damaged due to overheating, and table moving mechanisms can get damaged due to mishandling.

The machine you select for business should require low maintenance. The maintenance required should be easy to perform, like a machine that is easy to clean and inspect. It is important as maintenance involves both time and money.

With maintenance, it is also necessary to check that the machine is easy and safe to operate. This machine involves a laser beam with high energy and power. So, even a small defect in the machine can cause serious problems for its operator and surroundings.

9. Cost of Machine

Depending on your business requirements, you might need one or more machines. You might also need more than one type of machine for your business. So, in larger setups, it’s necessary to consider the cost of the initial setup.

The cost of the machine is usually compared with the cost of operation. If a machine costs less initially but costs more during operation, then it will not be cost-effective in the long run.

Similarly, if a machine costs more in initial setup and costs less in operation. Then it will be cost-effective in the longer run only for batch-type production models.

10. Selecting Machine Variant

With a basic understanding of the business and related industry, it’s time to select the basic variant of the best laser engraver. You can pick any basic laser engraver machine variants mentioned above.

You can get the fully enclosed laser engraver if you are concerned about safety. These enclosed machines have an automatic system that stops the laser beam as the machine door is open. So, these machines are the safest option for laser engravers.

Similarly, you can have a desktop-type laser engraver. There are single-laser head and multi-laser head desktop laser engravers. This machine variant is cost-effective, and the multi-laser head option can be faster than a fully enclosed laser engraver.

Your business idea includes delivering small batches of engraved products. It is better to invest in a desktop laser engraver machine with a station rotating table. This machine not only increases production speed. It also decreases the labor and time involved in installing and removing products.

It is important to note here that the selection of the machine variant is at the last position. It is due to the reason that the variant will be selected after all the factors have been considered.

Conclusion

Selecting the best fiber laser engraver for your business involves considering various factors. Such as your specific engraving needs and material compatibility. Other factors include machine size and power, maintenance requirements, and cost-effectiveness.

By thoroughly evaluating these aspects, you can ensure that you choose the best fiber laser engraver machine. A machine that will enhance your operational efficiency, and meet your business goals. All this will ultimately contribute to your success in the competitive laser engraving market.