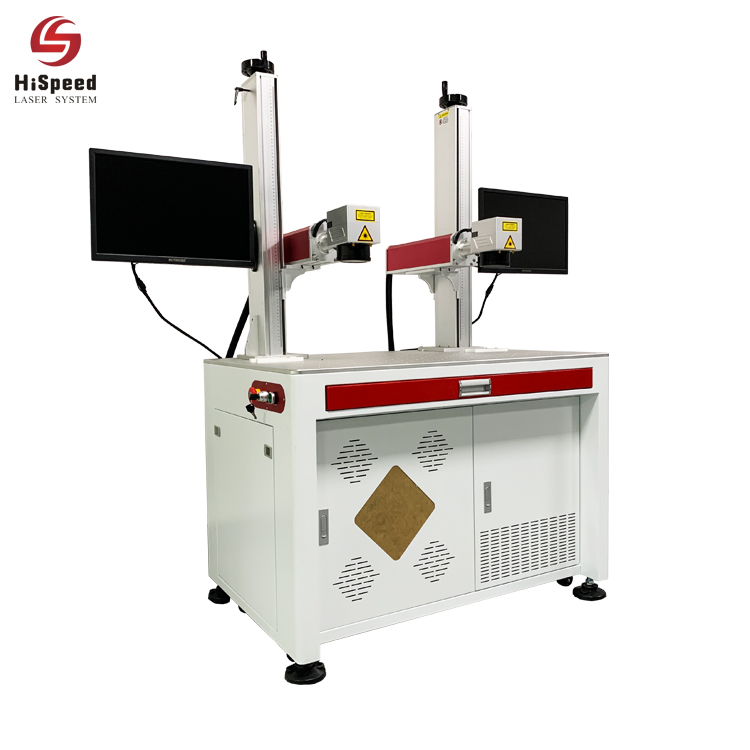

Over time, we often use both laser and non-laser technologies in engraving. But after using it, I found that metal laser engraving is the best among all materials. The industry will use the advanced technology of metal laser engraving. Metal laser engraving machine can be divided into metal fibre marking machine and metal laser engraving machine.

We often use metal laser engraving machines in our daily engraving work. It is an improved version of the traditional engraving machine. This metal is strong, durable, heat-resistant and soft. It has a beautiful appearance. At the same time, the metal laser engraving machine is more convenient than ordinary engraving machines.

Popular reason

The application range of laser engraving machine is extensive. Can use it for communication equipment, electronic equipment, instruments, etc. The intensity of laser engraving is very high. You can leave a permanent mark on the part. This function can maintain the uniqueness of the merchant’s product. And the engraving mark will never disappear. Therefore, large independent companies like it very much. A computer controls the laser engraving machine. It will not deform the device after the engraving is completed. At the same time, metal laser engraving is fast and accurate. It can effectively save materials.

A computer controls the laser engraving machine. Therefore, you can also adjust the size of the laser beam area. The lens with small spots is used for high-resolution engraving. A large spot lens is used for lower resolution engraving. So can apply it to various occasions. The metal laser engraving machine is viral among business people. At the same time, it uses the rate to control the cutting depth. So the laser engraving machine can also adjust the speed and save time.

The principle of laser engraving machines

Next, let’s talk about the working principle of the metal laser engraving machine. The application range of laser engraving machine is extensive. Can use it for communication equipment, electronic equipment, instruments, etc. The intensity of laser engraving is very high. You can leave a permanent mark on the part. This function can maintain the uniqueness of the merchant’s product. And the engraving mark will never disappear. Therefore, large independent companies like it very much. A computer controls the laser engraving machine. It will not deform the device after the engraving is completed. At the same time, metal laser engraving is fast and accurate. It can effectively save materials.

A computer controls the laser engraving machine. Therefore, you can also adjust the size of the laser beam area. The lens with small spots is used for high-resolution engraving. A large spot lens is used for lower resolution engraving. So can apply it to various occasions. The metal laser engraving machine is viral among business people. At the same time, it uses the rate to control the cutting depth. So the laser engraving machine can also adjust the speed and save time.

Laser engraving machine can improve the efficiency of engraving. The surface of the object carved with it is best to be smooth. If we engrave non-metallic materials, then we can quickly reduce their temperature. It can perform fine engraving on various non-metallic materials. Metal engraving machine can be divided into two kinds of laser marking machine and laser engraving machine.

Application of laser engraving machines

1. Application in the decoration industry.

Metal laser engraving machines have many applications in the decoration industry. I will focus on wood carving next. The first one introduced is the log. Logs are untreated wood. It is the most common laser processing material among us. It is easier to carve and cut than other woods.

Each type of wood has its characteristics. The laser evaporates the wood quickly. Engraving machine engraving wood is more suitable for group carving. When we are carving, the carving depth should not be too deep. The edge of the cut plywood of wood is black. But the degree of blackening depends on the wood of the plywood.

Also, if the colour of the wood is very light, you can increase the engraving speed and try to engrave multiple times. In some woods, oily smoke will stick to the surface of the wood during the carving process. If the wood has been painted, please wipe it carefully with a damp cloth before carving. Try to wipe the wood surface clean. Because doing so can prevent stains on the surface of the final product. You can moisten the wood with water or take some measures to avoid floating wood particles produced in carving wooden materials. Because the engraving machine is blocked, long term accumulation will affect the service life.

2. Printing and packaging industry

With the popularization of laser engraving technology, laser engraving technology is gradually applied to printing plates on paper packaging materials in the printing and packaging industry. The cost of metal laser engraving is meagre, only a quarter of the price of resin plates. Therefore, laser plate making is usually used as a carton packaging printing plate in the current printing and packaging industry. Metal laser engraving uses laser dots for engraving. Therefore, we should try to use metal laser engraving. Because it can reduce the colouring process, save costs, and it also enriches the expression techniques of sculpture.

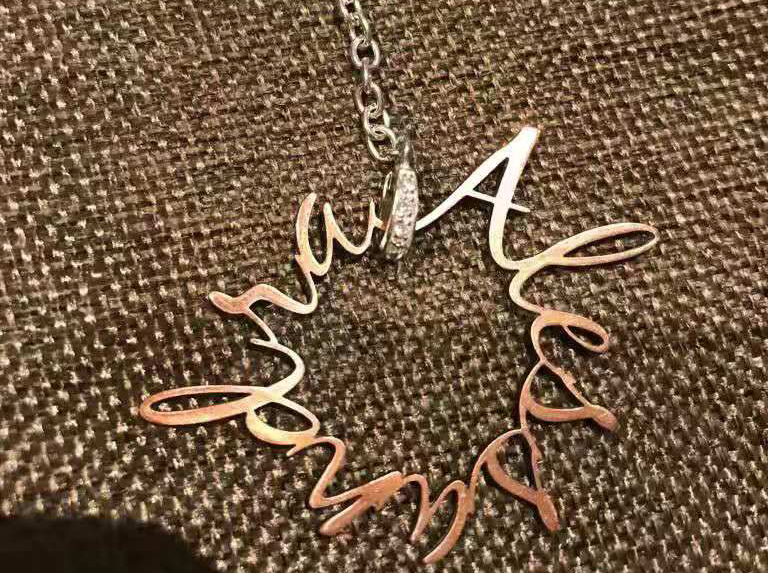

3.The application of metal laser engraving in the craft industry

Laser engraving crafts refers to the use of lasers to project onto the surface of the material. The laser makes physical and chemical changes on the surface of the material to obtain engraved crafts. The most common material in our daily life is plexiglass. It is easy to be laser cut and carved into various shapes. And the cost is relatively low, so it has become the most commonly used engraving material in the handicraft industry.

After laser engraving, it will become white in sharp contrast with the original transparent texture. After engraving can produce a contrast effect. The plexiglass produced by calendering is still transparent after laser engraving. Such glass has no contrast effect, so it is rarely used now.

Another metal laser engraving technique is to try to turn the craft into flat crystals or glass. It is also necessary to try to find a relatively flat side during engraving. Engraving can use coloured paper to engrave glass materials. Wet the coloured paper when carving, and cut it to the sculpture’s size as much as possible. Then stick it on the glass’s surface and wait for the coloured paper to dry completely before engraving. Also, a thin layer of soap can be applied to the area to be carved because soap helps to dissipate heat.

4. Application of metal laser engraving in the leather industry

Now the leather industry also uses metal laser engraving machines. It eliminates slow speed, complex typesetting, low efficiency and severe waste in traditional manual cutting. The metal laser engraving machine is fast and easy to operate. It has brought considerable benefits to the development of the leather industry. Input the cropped graphics and size into the computer. The laser engraving machine cuts the entire material into the required finished product according to the computer’s data.

The metal laser engraving machine does not require tools and moulds, saving a lot of human resources investment. Therefore, laser engraving machines are also widely used in the leather industry. Laser cutting machines have many advantages compared with traditional cutting methods. First of all, the first advantage is that the edges of the leather cut will not turn yellow during the laser cutting machine’s cutting process. It can also automatically close or curl the edge to deform.

The size of laser-cut leather is consistent and precise. Can cut many complicated shapes through computer design graphics. It has high efficiency and low cost. No mechanical pressure is applied to the workpiece during processing, safe operation and simple maintenance.

Finally, do you know how to maintain the metal laser engraving machine?

The consumable of the laser engraving machine is the laser head. It is recommended not to over-engrave at once. It would help if you let the machine rest and keep the power to continue to engrave.

How to choose a suitable laser engraving machine.

So how do we choose a suitable laser engraving machine? I think persistence alone is no longer enough. We must consider all aspects. From an aesthetic point of view, we must choose the currently popular cabinet design style. Its appearance is beautiful, and the internal structure is orderly. This is also ideal for saving space.

You may think that appearance is not essential. But in fact, the unique internal structure design is necessary. In the overall planning, the design should avoid using the exposed structure of traditional machine tools. The shell should enclose the internal organization so that its shape is as large as a conventional machine tool. It must be fully functional, so it is easy to operate and clean, and beautiful.

The design of the metal laser engraving machine should be safe and reliable. It must meet the aesthetic and work needs of users. Give people a simple, secure and reliable experience. Its electronic control system is fully automatic, and the operations of the control components are concentrated on the computer control panel. We press the switch button to automatically enter the fully automatic operation state, safer and worry-free.