Portable engraving, a technology that is used for leaving marks, adding symbols, or adding pictures on a particular object. It is the process, which involves changing the chemical or color, foaming, or melting to give it a new texture or shape. Here in this method, the usage of the fiber laser source is involved. The transmission of the laser is all done with the help of the high-speed galvanometer, which is used for making marks on the particular object.

Understanding all about the portable engraving machine is very much difficult. Here in this post, we will all discuss all about the portable laser engraving machines. And what are the different uses portable laser engraving machine. So, let’s have a look at the information below:

Different materials on which the portable laser engraving machines are suitable

There are different types of materials, on which the portable laser engraving machines are suitable are:

Plastics

The plastics are the only material, which is all successfully engraved by laser. The range of plastic, which can be engraved via laser machines includes ABS, PBT, and many more.

Metals

With the help of the laser machines, the metals can also be engraved and such metals include ABS, PBT, and many more. The laser engravings can be easily obtained on metals namely, copper, aluminum, gold, silver, platinum, and many more.

Jewelry

Fashion jewelry engraving is also one of the main engraving businesses of the portable laser engraving machine. It includes silver jewelry, nameplates, rings, jade, etc. You can even choose the mini hand-crank laser engraving machine to do the jewelry engraving by yourself at home.

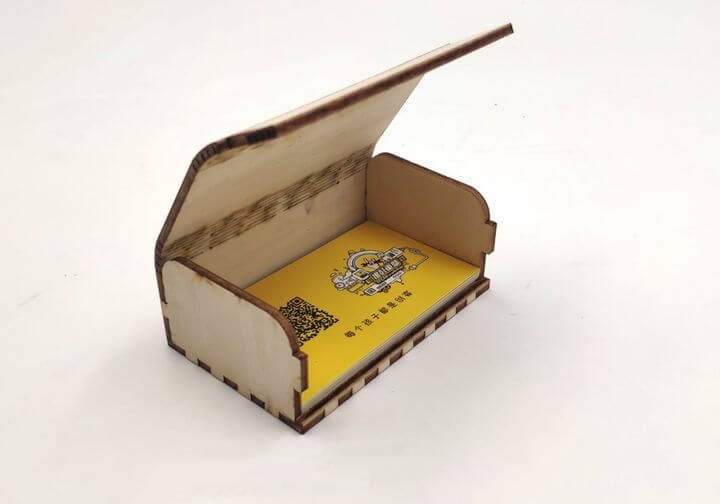

Wood

Portable laser engraving machine engraving wood is also possible. You can also engrave puzzles, set your desired difficulty. You can also use the portable laser cutter to etch round wooden beads. In short, as long as the wood material engraving objects can use the portable laser cutter for perfect engraving.

Amazing Features of portable engraving machines

After understanding all about the different materials on which the laser machine works. You need to understand all the amazing features of portable engraving machines.

The portable engraving machines are the ones, which all work on the uniform power density, and they are designed in such a way so that there will be anti-reflection of the isolator will be increased. This makes the machine play out the tasks successfully on high intelligent materials, for example, aluminum, copper, gold, and silver without the shadow, and so on

The portable laser engraving machine can work at high paces with practically no deviation. Portable laser marking machine shows great steadiness for a little volume creation cluster. The machine is changed with the most recent innovation and has taken on an inserted working framework that confers a decent touch interface and incredible control framework. A portable laser marking machine is fit for meeting a large portion of the modern requests and its conservative design makes it an exceptionally viable piece of apparatus.

Amazing uses of Laser marking

With the advancement in technology, laser marking is number in a number of applications and here we have countless technologies on which laser marking is used. Here now, we are going to discuss all its uses in detail.

Jewelry

The portable laser marking machines are used in the jewelry designing industry. With the help of the machines, the designs can be achieved in an accurate manner. All the designs are made in such a way so that there will be no harm to the actual object. Designing anything on jewelry is completely time-saving. Even though, it is the best method, which is all done on the fragile components. It makes goldsmith use a laser marking machine, to add creative designs to jewelry. The final results for the jewelry pieces are completely ultimate.

While using the portable laser making there is not as much as space required. A machine with model FIberLux Nano, which is all used on jewelry to give an ultimate look to the pieces of jewelry.

Marking on the industrial products

With the help of portable laser marking machines, it becomes very much easy to add marks on a large number of industrial products. Even though, such laser machines are also used in the Government sector. The marks, which are done by the machines are completely guaranteed and everything is all done with the help of the software, which is all available with the machines.

Photoengraving

This makes the machine play out the tasks successfully on high intelligent materials, for example, aluminum, copper, gold, and silver without the shadow, and so on. The laser checking machine can work at high paces with practically no deviation. This machine shows great stability for a small volume creation cluster. This portable laser engraving and cutting machine features the latest innovations and a plug-in working framework. It can offer a decent touch interface and an incredible control framework. The type of machine is suitable to meet most modern requirements and its conservative design makes it a very viable device.

Micro-Cuts

An effectively aligned laser marker can cut surfaces a couple of millimeters thick, ensuring amazingly precise mediation. The method requires a specific measure of time, in light of the fact that the laser cuts by more than once ignoring a similar piece of the article, however, the outcomes are especially acceptable according to the perspective of precision.

Ultimate methods used for portable laser marking

Depending upon the type of the application, the portable laser marking methods are designed and here are some of the most common and widely used laser marking methods.

Portable Laser Engraving

In the portable laser engraving method, first of all, the metal is removed from the material. It let the mark be created on the surface of the object and it creates a depression. The objects, which can bear laser engraving are plastics, stone, ceramics, and many more. During the process of laser engraving, the metal first melts and evaporates when the laser gets impacted on it. It also made the object to change its color, which make the object to be distinctive.

Carbonising

Carbonizing is the laser marking process, which is all done on leather. It is the process where the laser process is done in the dark. During this process, the laser lets the plastic bonds break, which releases oxygen and hydrogen into the atmosphere.

But there are some disadvantages of this laser marking method. One of the disadvantages of this method is that it is not a good technique for darker objects. It is the process, which is all used for the objects, which can be paper, leather, packing material, mark wood, and many more.

Foaming

When it is about adding marks on the light material, then the foaming method is the perfect one. There are many applications for which the foaming method is best. This process is all used to generate heat on the material. As its name describes, that it is the process which is having bubbles emitted as its consequence. These bubbles are very much beneficial in reflecting lights and make this laser marking process the best choice for dark-colored objects.

Removing

This laser stamping technique is particularly appropriate for covered materials. In this cycle, the laser eliminates a layer of the workpiece to uncover the layer under (substrate). If the two layers have various tones, it creates a difference.

Covered materials, like anodized aluminum, show fantastic markings with this technique. Utilizations incorporate names, bundling items, and fittings. Materials that normally function admirably with this cycle are metals with coatings, covers, thwarts, and movies.

The removable metal assimilates the hotness and disintegrates where the laser encroaches on a superficial level. This laser scratching process likewise finds applications in the auto business where day/night configuration is liked. It is basic that the topcoat has an unexpected shading in comparison to the base material for productive and neat checking. One more name for this cycle is removal.

Staining

Once in a while, the substance piece of the material can be utilized for our potential benefit with regards to laser drawing. The laser pillar produces limited warming. This warming prompts a substance response. In the event that the side effects have an alternate tone, they give high differentiation any place the laser interacts with the surface. Staining needs no entrance. The age of the imprint relies upon the oxide layer’s thickness.

Different varieties of machines that are suitable for laser marking

The varieties of portable laser engraving machines are all designed according to their uses and here we have the best options of machines that are used to undergo the operations of the laser.

There are different advantages and disadvantages of each of these laser marking techniques. They are designed according to budget, applications, and quality. Here we are going to explore one of the best varieties of machines. So, let’s have a look at the information below

CO2 Laser Marking Machine

CO2 laser checking utilizes CO2 gas in a fixed chamber as a laser source. As the name proposes, the CO2 laser is a gas laser. An electrical flow siphons energy into the gas which then, at that point, transmits radiation. This radiation is enhanced utilizing mirrors and focused on the material for stamping. The CO2 laser has high shaft quality and similarly great proficiency.

Fibre Portable Laser Engraving Machine

The most famous arrangement for laser checking today is fiber laser stamping. It is a strong state laser. In this framework, an optical fiber doped with an uncommon earth component is utilized as a laser source.

This arrangement checks all the more viably and is additionally more flexible, more modest in size, and has quicker stamping speeds. It additionally gloats of insignificant support and zero consumable necessities.

The expense of possession is less contrasted with different machines and the framework is dependable. It can check even troublesome materials, like PCBs, plastics, nickel, and gold plating. It might likewise be utilized for touchy materials and layers. Fiber lasers are most appropriate for laser scratching utilizing the tempering, etching, and plastic stamping processes. They additionally have a long existence of at least 25,000 hours.

MOPA laser is an exceptional kind of fiber laser. MOPA lasers are amazingly adaptable as the beat term can be changed. This empowers them to work with countless materials.

YAG Laser Marking System

This technique utilizes Diode Pumped Solid State (DPSS) innovation to siphon neodymium or ruby-doped YAG gem with a laser diode to deliver laser beams. Its frequency is by and large multiple times less than CO2 which keeps it from being invested in an assortment of materials. Therefore, it must be utilized with a predetermined number of materials.

Amazing advantages of laser marking

Here are amazing advantages of portable laser engraving machine that you should know before having its services. It has extremely high effectiveness for photoelectric transformation creating immaterial flaws in the activity. The laser stamping machine has reduced design and high framework incorporation. The way that it is viable with programmings like CorelDraw and AutoCAD makes it the apparatus of most extreme significance in ventures. It additionally upholds various expansions, for example, PLT, PCX, DXF, BMP, and so on, and straightforwardly utilizes SHX and TTF text styles.

Precise process

While talking about the accuracy of this process, then it is extremely price. Even though, it is also used for smaller objects even on printed circuit boards.

Safe for environment

The environment is our biggest concern these days and laser marking is the process that is safe for the environment. It is the process, which does not produce any toxic product into the atmosphere.

High-speed process

As compared to the other method, the laser is a fast process. The process of cutting involved in this is very much fast and it automatically reduces the cost of the process.

Low Cost

The operational cost for the process of laser marking is very much low. Even though, you do not need any manpower when you are working on it. The machinery gets automatically installed when you are working on it.

Get automatically adjusted for different material

The other major advantage of a portable laser engraving machine is that this can be adjusted on different materials. These materials include stainless steel, aluminum grades, and many more.

Conclusion

At last, we hope that you have clear with all about the uses of the portable laser engraving machine. We believe that after reading the above information, you can easily opt for laser services.