Are you still worrying about how to make money? The acrylic laser engraving machine is constantly improving. It has dramatically improved its productivity and product quality, and value. Suppose you want to buy an acrylic laser engraving machine. In the following article, we will provide you with a getting started guide. This article will guide you to use an acrylic laser engraving machine to make money. And teach you how to choose the suitable acrylic laser engraving machine for your business.

We will also show you how to use the acrylic laser engraving machine to make the engraving materials play the best effect and maintain the acrylic laser engraving machine after having the laser file.

How to use acrylic laser engraving machine to make money

Many people see that acrylic laser engraving machines are becoming more and more popular. They want to buy an engraving machine and open one or two shops to do business. Then open an acrylic laser cutting machine shop to make money? Next, let’s briefly talk about whether the laser engraving machine makes money? Presumably, this is a question that many customers want to understand. Generally speaking, the price of an acrylic laser engraving machine is relatively high. Many customers may worry about buying it at such a high price, whether it will not profit in the future. But I am here to tell you clearly that your concern is unnecessary.

The acrylic laser engraver is easy to operate. It is controlled by a computer system and can be processed at any time after setting the data. We need to continue to study and learn to enhance the ability of laser engraving technology. In this way, we can quickly operate it and use it to bring us money.

Seventy percent of our business is based on our business capabilities. We must constantly improve our visibility and attract a large number of customers. Only in this way can our company get better and better. This means that they can play their advantages in more fields and bring you certain economic benefits. Print the logo and basic product information on the product. Acrylic laser cutting machine use particle beams to make permanent marks on the surface of different types of substances.

Advantages of acrylic laser engraving machine

1. Acrylic laser cutting machine has better beam quality and smaller focusing spot diameter than traditional solid-state laser engraving. Acrylic laser cutting machine’s excellent beam quality and 20W laser power make the engraved metal products have straight and clear edges. So acrylic laser cutting machine is especially suitable for precision and fine metal products depth engraving.

2. Laser engraving machine for acrylic is all controlled by the computer system. The depth engraving is more accurate and convenient to adjust.

3. Laser engraving machine for acrylic has a low cost of use. The electro-optical conversion efficiency of up to 30%, the power consumption of the device is only 600W

4. Long service life of acrylic laser cutting machine. In the process of future use, if there is a failure, free consultation, and maintenance.

The most commonly used engraving and processing material is acrylic, second only to wood. Acrylic engraving machine is easy to cut and engrave. There are various shapes and sizes, and the cost is relatively low.

1. Carving

Under normal circumstances, acrylic is engraved from the back. In other words, the acrylic engraving machine cuts from the front to make the finished acrylic more three-dimensional. When laser engraver for acrylic back engraving, please mirror the graphics first. The engraving speed of the laser engraver for acrylic should be fast during use, which will make the pictures more smooth. However, if the engraving power of laser engraver for acrylic is too high, uneven stripes will appear on the bottom surface.

If you want to engrave deeper, you can move the acrylic cutting machine a few times. In the case of acrylic cutting machine back engraving, for partial coloring, you should engrave the off-color part darker first, then sand it with flame, and then fill in the color. If not polished, the acrylic color will be uneven when viewed from the front.

2. Cut

Acrylic is relatively easy to cut. If the customer’s requirements are not high, it can be delivered after cutting without flame polishing. Otherwise, a blowing device should be used when cutting to improve the quality of the cut. When cutting acrylic that exceeds 8mm, it should replace large-size lenses.

Note: The operator cannot leave when the acrylic cutting machine is cutting acrylic. A laser engraving machine for acrylic cutting may have a flame.

3. Clean

After we have carved the plexiglass, we can use a damp cloth to clean the surface.

The above is my summary of the use steps of the acrylic laser engraving machine. I hope it will help you.

When we use an acrylic laser engraving machine, it will generate smoke, so don’t worry about this is normal. Due to the laser’s high temperature, PMMA (acrylic) produces fine PMMA particle smoke, and PMMA itself has this odor characteristic. Still, it is solidified and does not diffuse at an average temperature. So don’t worry too much about the smoke generated during use. But long-term inhalation is not very good. Next, I will explain to you the three most common treatment methods.

Filtration and adsorption:

We put filter materials in the place where the machine produces particulate smoke. We need to arrange the filter material perpendicularly or parallel to the flow direction of the flue gas, so that the purification efficiency of the flue gas can reach more than 80%.

Electrostatic purification:

The electrostatic deposition method introduces the oil fume into a high-voltage electric field. The particles in the oil fume and fire fume are charged and moved to the dust collector under the electric field and deposit force. The purification efficiency is usually over 85%, and the pressure drop is small;

Low-temperature plasma:

The principle is to use the high-voltage electrostatic method while setting a plasma field at the front end of the electrostatic field, and use the large number of free radicals excited by its energy to degrade the oil fume particles and reduce the viscosity; during the plasma generation process In the medium, the instantaneous energy generated by high-frequency discharge can open the chemical bonds of some harmful gases and decompose them into elemental atoms or harmless molecules. This technology is currently on the market to treat oil fume and fire smoke, with a high removal rate (less than 90%), good gas effect after treatment, and easy maintenance.

We aim to reduce the smoke and smell produced by the laser machine, hispeed combined electrostatic and plasma to develop a band electric ion exhaust gas purifier using high-voltage electrostatic purification technology. The laser flue gas is collected by high-voltage electrostatic field adsorption. Under the action of high-voltage electrostatic and low-pressure adsorption, the exhaust gas in the laser exhaust gas is purified (purification rate>95%) and then discharged to the outdoors through the induced draft fan.

The above are some basic knowledge about the acrylic laser engraving machine I prepared for you. I hope to help you.

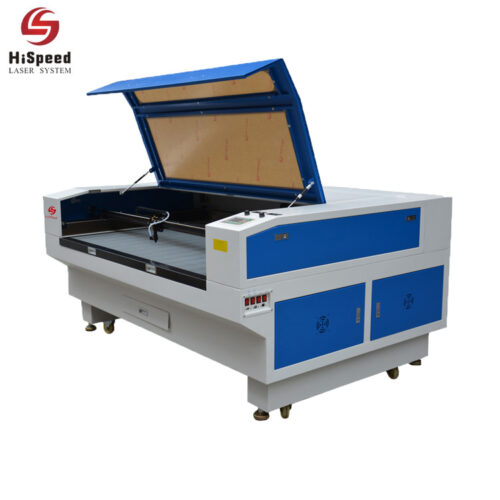

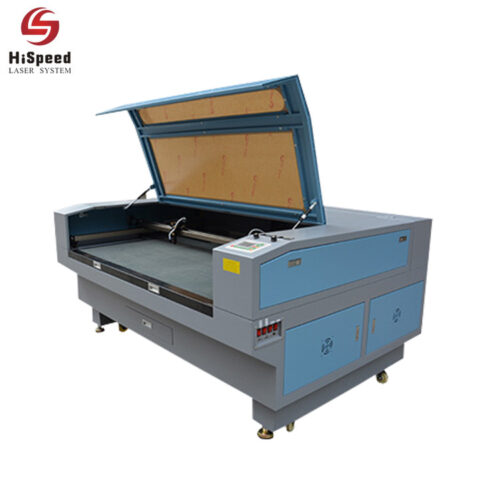

The acrylic laser engraving machine is a type of laser equipment for engraving acrylic in various depths. Such laser equipment generally uses CO2 lasers.

Casting and calendering. Laser engraving is mainly made of plexiglass produced by casting. The frosting effect it produces after laser engraving is very white, which is in sharp contrast with the original transparent texture. However, the calendaring method’s plexiglass is still transparent after laser engraving, and there is no contrast effect.

Under normal circumstances, plexiglass adopts the back carving method. That is to say, it is carved from the front and viewed from the back. This makes the finished product more three-dimensional. When engraving on the back, please mirror the graphics first, and the engraving speed should be fast, and the power should provide below. If the power is too high during engraving, uneven stripes will appear on the bottom surface. If you want to engrave deeper, try impressing several times.

Acrylic laser engraving machines generally use electric lifting working platforms suitable for engraving and processing objects of various thicknesses, which is convenient and fast. It dramatically improves work efficiency and processing quality. It can also be equipped with a rotary engraving device to engrave various cylindrical and vertebral objects accurately. Compared with the traditional knife mold, the acrylic laser engraving machine has fast speed, high precision, and diversified engraving patterns.