Relief is a type of design or sculpture and a fascinating art form. It can either be raised or recessed relative to the surroundings. It may come in various forms—for example, carvings on walls, coins, or engraved surfaces. Relief engraving is a type of 3D engraving. It is relatively more complex than 2D engraving.

You can do relief engraving on various materials. However, it is primarily popular in metalworking, wood carving, and some acrylic & plastic projects. In this article, you will explore relief carving. You will learn more about its types and, most importantly, about laser relief carving.

What is relief Engraving?

Relief engraving is a type of 3D engraving on the surface of a material. It gradually removes material to make patterns or complex shapes. Note that you can create either raised or recessed designs.

Relief carving is especially popular in art, jewelry, and other manufacturing processes. It adds detail and textures to an object. Most modern relief engraving uses advanced tools. Lasers, chemicals, and machines make this process faster and more precise. However, traditional methods, like hand relief carving, are much slower but are still valued for their artistry. Thus, hand engraving is much more expensive than laser or chemical engraving.

Types of Relief Engraving

Relief Carving typically has four main types. Each type has unique pros and cons, which we will discuss in this section. Let’s find out more.

Hand Relief Engraving

Hand relief engraving is the oldest technique. It needs skills and patience. Artists typically use chisels, gravers, and hammers to create raised or recessed patterns on objects. They carve directly onto the surface. This method is time-consuming yet produces unique and artistic results.

Pros

- Hand engraving produces a very unique result.

- The best thing about this technique is that you can work with small to large objects. There are no workspace limitations.

- In hand engraving, you have the option to control the creativity.

Cons

- Hand relief engraving is a super slow process.

- It needs expertise. Otherwise, you will mess up every time you create complex shapes. Only artists and professionals can do this.

- Hand carving is typically more expensive than other relief engraving products.

Mechanical Relief Engraving

Mechanical relief engraving typically uses CNC or manual machines. These machines have rotating cutting tools, like routers or milling machines, and carve designs into the surface.

This method is faster, though. However, it can not create complex patterns. It is common in manufacturing and mass production.

Pros

- CNC machining is faster than hand engraving.

- It is suitable for large-scale production.

Cons

- The relief carving design is very simple. You don’t have many options to create complex shapes and designs.

- The initial cost of CNC machines is very high.

Chemical Relief Engraving

Chemical engraving is also known as relief etching. This method typically uses acids or chemicals to remove material. You may wonder how creating such complex shapes on the surface is even possible. If you think about it technically, it is typically a very easy method.

First, you need to apply a coating with a resistant material. Then, you can expose the design of the chemical solution. The solution will automatically eat away the exposed areas.

Pros

- Chemical relief carving is much more accurate than hand engraving.

- This method is suitable for intricate designs.

Cons

- This method is not environmentally friendly.

- Although chemical engraving is much more accurate, it is less precise than laser engraving.

Laser Relief Engraving

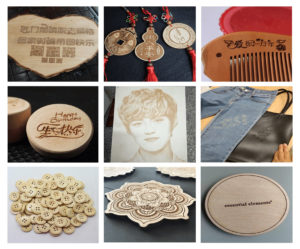

Laser relief engraving is the most modern technique. It uses high-powered lasers to engrave surfaces. The laser gradually removes materials with heat. The whole process is done with tiny laser beams. So, you can guess how accurate this process can be.

This method is fast and very accurate. Laser relief engraving is generally ideal for the most detailed and complex designs. It is a very versatile method that works on all hard materials. Whether you want to work on wood, metal, or plastic, laser relief carving is the technique you should use.

Pros

- Laser relief engraving is an incredibly faster and more accurate process.

- It is a versatile method that works on all types of materials.

- Laser relief carving doesn’t need extra tools.

- It is environmentally friendly.

- You don’t need expertise for this job. All you need to do is prepare the design of the software. Once you run the laser machine, it automatically creates the designs.

Cons

- Laser engraving needs a high initial cost.

How to Laser Relief Engraving

Laser relief engraving is almost similar to other laser carving processes. What makes it different is preparing the design file and laser parameter settings. However, let’s go through the step-by-step process.

Material Selection

First, you will have to choose the right material for your project. Without selecting a material, you can not decide on laser parameter settings. Wood, metal, and acrylic are used for relief engraving.

Design Preparation

The main difference between the other laser engraving projects and this one is the design and laser parameter settings. In this step, you can use various designing tools, such as Lightburn or RDWorks. You must ensure that the design is detailed and precise.

Laser Engraving Parameter Settings

This is the most essential part of laser Relief engraving. In this step, you will first need to prepare two layers of your image. You can adjust the contrast of the second layer compared to the first. The reason for making two layers is that the laser will engrave the second layer and then engrave the first one.

Once your image layers are ready, adjust the laser engraving parameters. Pay attention to the power, dpi, and dot duration.

Test the Settings

Before you start the actual process, it’s always wise to test the setting first. This way, you can reduce waste and save costs. In this case, you can use a scrap piece of the same object you are about to make the relief.

Material Engraving

Before you start the engraving process, you can use a support tool under the object. Then, focus the laser beam in the middle of the object. Once you have started engraving, carefully observe the whole process.

Step #6 Cleaning and Post Processing

Once the relief is ready, you may have to clean it, especially when dealing with wood reliefs. As you know, woods are more prone to making burn marks. You can also apply various coatings to improve the aesthetics of the relief.

Sum Up!

Relief engraving offers us artistic and practical applications. This technique allows you to create 3D objects with detailed shapes and designs. You can use various methods, including hand relief, mechanical, chemical, and laser carving.