1. The present and past of welding machines:

Present: Laser welding machine

Past: Argon Welding Machines

2. Working principle of laser welding machine:

Laser welding machine utilizes high-energy laser pulse to locally heat the material in a tiny area, the energy of laser radiation spreads to the interior of the material through heat conduction, melting the material to form a specific molten pool.

It is a new type of welding method, mainly for thin-walled materials, precision parts welding, can realize spot welding, stack welding, sealing welding, etc., high depth-to-width ratio, small weld width, small heat-affected zone, fast welding speed, beautiful, no need to deal with the post-welding treatment or only simple treatment, small focusing spot, high positioning accuracy, easy to realize automation.

3. The features of Laser welding machine:

> Adopts fiber laser source, high optical power density, good spot quality, stable output power, high quality welding effect can be achieved.

> Integrated structure design, small floor space, easy to carry.

> Handheld welding head accord with ergonomic design, light and practical.

> Small welding seam with small thermal influence, firm welding, high precision welding quality can be achieved, part of the welding without grinding.

> Easy to learn and use. With safety protection, low dependence on traditional welding experience, do not need a certificate to work.

> Low operating cost, power consumption 3~6kw per hour, except lens and nozzles no other consumables.

4.Comparison of Laser welding machine and Traditional Argon Arc Welding:

Laser welding machine:

(1).Simple operation, easy to get started: no experience required, skilled operation in half an hour, welding speed is 3-5 times faster than argon arc welding, saving 2 welders!

(2).Fast welding, the heat-affected zone is small, the weld seam is smooth, and the subsequent grinding process is reduced.

(3).High strength, can be welded Ultra-thin materials can be welded with filler wire or without wire.

Traditional Argon Arc Welding:

(1).High technical requirements and high labor cost .

(2).Slow speed, low efficiency and easy deformation.

(3).The weld seam is thick and requires secondary grinding.

(4).Large limitations, can not weld too thin materials, there are consumables, need to be filled with wire, and there are pores that are easy to weld through.

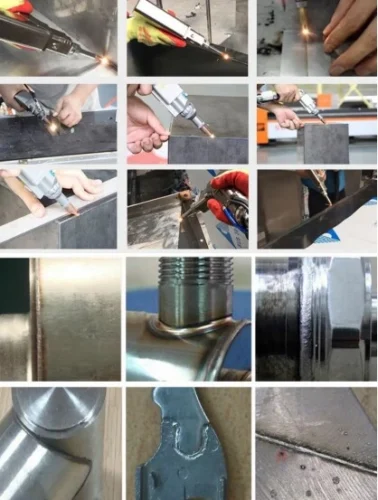

5.The application of Laser welding machine:

1). Industry:

Metal, Sheet metal, Mold, Electronic machinery, Kitchen and Bathroom appliances, Digital products, Billboards, Windows and door frames, Household appliances, Handicrafts, Hardware and building materials, Auto parts and many other industries.

2).Applicable materials:

– Common metals and alloys (iron, copper, aluminum, magnesium, zinc, etc);

– Rare metal and alloy (gold, silver, titanium);

– Metal oxide (either all kinds of metal oxide);

– Special surface treatment (anodized aluminum, plating surface);

– Plastic and ABS material (electrical appliances shell, daily necessities)

– Epoxy resin (electronic originals of outfit, insulation), ceramics and silicon wafers.

6. Key parts in Laser welding machine:

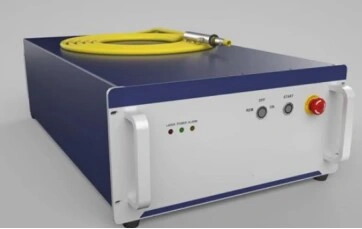

1.Laser Generator:

Hand-held laser welding machine adopts continuous fiber laser source.

Longer lifetime, higher photo-electric conversion rate, can work 24 hours continuously, long maintenance-free period and low maintenance cost.

2.Welding Head:

Light shape, Ergonomic design, advance structure, and reliable performance ensure comfort grip and simple operation. Expands the tolerance range and welding width of the processing parts, and solve the disadvantage of minor, laser welding spot, and provide better welding forming.

3.Control System:

Self-developed good interactive control system which integrates laser control, galvanometer control, laser safety lock and excellent process algorithm. The original database can store rich process data and can be used in real time.

4.Nozzles:

The head could be equipped with a variety of angular nozzles (right-angle nozzle and edge nozzle) to meet the welding needs of different products.

Nice welding seam, fast welding speed, no consumables, no welding marks, no discoloration, no later polish.

5.Gas Supply System:

(1).The pressure of nitrogen or air should reach 0.2~0.3MPA. It is better to use nitrogen to weld, but if use air, the welding position will be oxidized and blackened.

(2).All gas should buy from your local city,China government not allow Chinese companies export gas to other countries.

6.Water Chiller:

Protect the normal operation of the machine to extend the service life.

7.Samples show: