Fiber laser engraving machine has variations of different working areas and power ranges. In some cases, lack of proper information may mislead to the wrong laser engraving machine option. Although in hiSpeed laser company, experts engineer introduces their customers to the machine’s capability before the buyer decides to buy. As a result, our customers can be more confident about their choices.

HiSpeed laser is famous for keeping a great collection of different laser cutting, engraving, and marking machines. The different types of laser sources are also popular in this collection. For example, CO2, fiber, and UV lasers have power variations. Therefore, we always give our customers a list of options to get the appropriate laser machine for their applications.

Therefore, to make it easy, we have prepared this article on how to buy an appropriate fiber laser engraving machine. From this article, you will understand the typical fiber laser engraving machine’s general and technical parameters. Therefore, you should consider these factors before choosing. In addition, this article will also illustrate the necessary diagrams to make the respective content straightforward.

Fiber Laser Engraving Machine Technical Parameters

Technical parameters such as working area, focal length, pulse frequency, type of laser power source, engraving speed, etc., are crucial parts of the fiber laser engraving machine. If you understand all these parameters, you can 95% confirm what you are buying. Besides, these technical parameters are also essential to understand for regular maintenance.

In addition, these technical parameters are also essential to understand while you are operating the machine. Therefore, you can properly position your laser beam on the surface of the material you want to engrave and get excellent engraving results. In the following, we will explain these seven technical parameters you should know before buying a fiber laser engraving machine or UV laser engraver.

Working Area

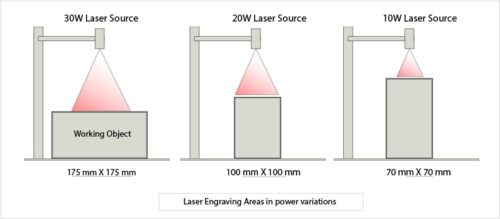

As mentioned, high speed laser engraving machines have different powers and table sizes. Therefore, it is crucial to consider the engraving area first. The working area might depend on what you want to engrave. In this case, the active region or engraving area determines how big you can get the operating table for engraving.

Technically, the working principle of a fiber laser optic gun is like a magnifying glass. The laser diffuses its focus point as long as it gets near the engraving object. Similarly, when the laser gun moves away, it scatters the beam, which results in unclear engraving.

On the other hand, the working area also changes depending on the laser power. For example, according to the following table, the optimum working area of a 10W fire laser engraving machine is 70 x 70 mm. But when you work on max power, the engraving can offer up to 100 x 100 mm. Although, we do not recommend working on maximum capacity as it decreases the durability of the laser tube.

|

HiSpeed laser Recommended Power source |

Working laser engraving Area when in optimum power |

Engraving area when in max power |

|

10W |

70 x 70 mm | 100 x 100 mm |

|

20W |

110 x 110 mm |

150 x 150 mm |

|

30W |

150 x 150 mm |

200 x 200 mm |

|

50W |

200 x 200 mm |

300 x 300 mm |

|

100W |

300 x 300 mm |

400 x 400 mm |

| 120W | 400 x 400 mm |

600 x 600 mm |

Focal Length

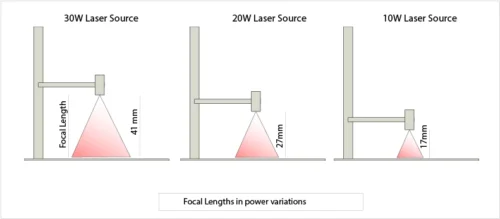

Focal length is the distance between the lens surface and the point where the laser beam converges. The typical variable focal length total is from 17mm to 440mm. High speed laser engraving machine comes with a variable focal length range. Therefore, you can customize the focal length of our laser engraving machine based on your projected product’s dimensions.

When choosing a fiber laser engraving, it is crucial to consider two critical factors: power range and focal length. Combining these two, you can get deep and accurate engraving.

|

Marking range |

Variable focal length range |

Variable focal length total |

|

70 x 70 mm |

100 – 117 mm | 17 mm |

|

110 x 110 mm |

168 – 195 mm | 27 mm |

|

150 x 150 mm |

231 – 272 mm | 41 mm |

| 200 x 200 mm | 303 – 392 mm |

89 mm |

| 300 x 300 mm | 413 – 602 mm |

189 mm |

| 400 x 400 mm | 960 – 1036 |

440 mm |

Frequency and Pulse Resolution

Pulse resolution combines two critical factors: frequency and maximum laser resolution. The resolution refers to the number of dots per inch. The higher the pulse resolution, the finer the engraving detail. Usually, the expected resolution range of a fiber laser engraving machine is 300 DPI (dot per inch) to 400 DPI. In case of high resolution, you might consider 600 DPI to 1200 DPI for unique photo engraving.

On the other hand, the higher the frequency spectrum, the better the engraving detail. In this case, the higher frequency of the laser spectrum creates a higher pulse resolution. Which ultimately leads to detailed and excellent engraving. The typical range of laser frequency in the HiSpeed fiber laser engraving machine is 20 to 120 kHz. However, in the case of higher resolution, the frequency range changes from 1 kHz to 850KHZ.

Power source

After considering the focal length and pulse frequency, you must review the power source used in the fiber laser engraving machine. In this case, the HiSpeed fiber laser engraving machines come with all popular laser power source options. JPT-X, Max, Raycus, and IPG are the most popular laser power source brands in the HiSpeed fiber laser engraving machine.

However, IPG and BCF are popular laser optic sources for jewelry engraving. On the other hand, Raycus, MAX, sino-galvo, and others are most suitable for other engraving applications. Raycus is one of China’s famous brands. Therefore, it is essential to check this equipment’s warranty as it is a crucial component of the overall system.

Engraving speed

The final technical parameter you should check is the productivity of the fiber laser engraving machine you are looking for in your business. Engraving speed is typically relative to the overall power of the device. For example, suppose you compare a 10W fiber laser marking machine and a 30W fiber laser marking machine with an optical fiber of 4000 mm per second. In this case, you will get a more satisfactory result for 30W than a 10W fiber laser engraving machine.

Therefore, the higher power marking laser machines can achieve higher engraving speeds. Therefore, considering the target production of your business using a fiber laser engraving machine, it is necessary to consider the engraving speed of the fiber laser marking machine.

Other Factors to consider

We have reviewed the technical parameters you must consider before buying a fiber laser engraving machine. However, it is also necessary to consider other factors, such as machine configuration, spare parts and accessories, machine budget, customer reviews, warranty, and after-sale service.

However, a good brand with good customer reviews highlights the product’s overall quality and durability. In this case, HiSpeed laser does not underestimate the quality, warranty, or after-sales service. Therefore, it is crucial to consider these factors.

Machine Quality and Configuration

As mentioned, the quality of a machine represents the brand. HiSpeed laser proudly serves its customers by ensuring the laser machines’ quality and configuration for decades.

HiSpeed fiber laser engraving machines come with a sturdy structure and precise assembly. Moreover, hiSpeed laser machines are some of the world’s most demanding laser engraving machines. Therefore purchasing a HiSpeed fiber laser engraving machine would be the best choice for your projected application.

Spare parts & Accessories

Popular brands or standard-designed machine parts are common in nearby stores. Unfortunately, if your fiber laser engraving machine has equipment with different standard sizes, it isn’t easy to find spare parts when you need to replace them. Therefore, it is essential to consider the spare parts and accessories of the machine. It would be best if the manufacturer offered you extra spare parts.

HiSpeed Fiber laser engraving machine comes with all the necessary parts and equipment you might need while in operation. We also recommend our customers get extra replacement parts for regular maintenance. In addition, we have continued to explore our network throughout the world. Therefore, our customers from any country can get the spare parts.

Machine Budget

Another significant factor to consider is your budget which is your business’s primary consideration. Therefore, we recommend our customers estimate the expected production rate per hour from the laser engraving machine. Besides, we also ensure the machine’s target job and engraving materials.

Depending on the customer’s these information, we recommend some of the most appropriate fiber laser engraving machines within their budget.

Warranty and after-sales service

Products warranty and after-sale technical support are significant for beginners. The supplier must commit to getting the machine on time and help you install and teach you how to use it. In addition, if necessary, the supplier must provide expert consultancy services after purchasing the machine.

With HiSpeed laser, you do not need to worry about warranty and after-sale services. We will recommend you the experts for your chosen fiber laser engraving machine. Besides, during operation, you can consult with our customer support. We hope we have an expert consultancy team ready to solve your problems.

Summary

A fiber laser engraving machine is an excellent investment to grow new business ideas. Therefore, your valuable asset is important to us. Consequently, we always want to give our customers the most appropriate laser engraving machine for their businesses. Besides, we also help our customers to understand every factor before choosing the best fiber laser engraving machine.

However, HiSPeed laser keeps an expert consultancy team for their customers. As a result, HiSpeed laser got excellent customer reviews for the last few decades. As a result, we continue to dominate the global laser machine market.