Laser Paper Cutter Machine

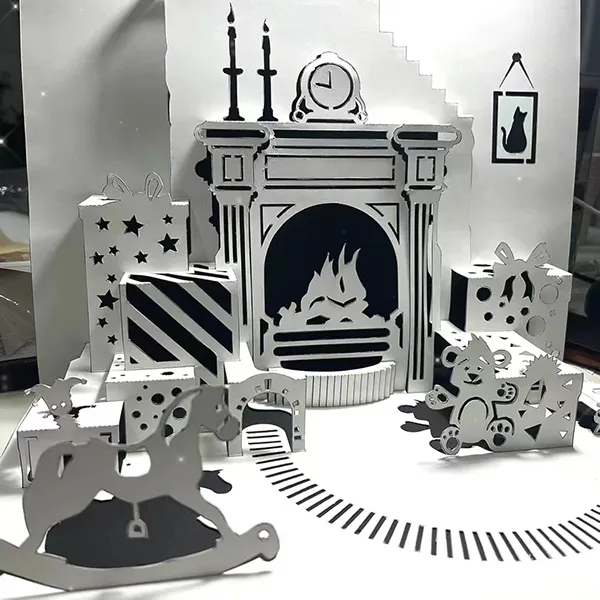

The laser engraving machine is an ideal tool for making paper cards. It can create unique designs and text by burning the paper with a focused beam of light. Compared to traditional cutting techniques, it is more precise and easier to generate original designs. The laser engraving machine can handle different types of paper, like cardstock, art paper, and handmade paper, with different thicknesses. As a result, it is used in the card-making industry to help people create more creative and distinctive paper cards

Our Laser Engraving Machine for Paper Card is a cutting-edge technology designed to create intricate designs and patterns on paper. With its high-speed laser, this machine can quickly and accurately engrave any design onto paper. It is perfect for creating custom invitations, business cards, and other paper products. At https://hispeedlaser.com/, you can find a variety of Laser Engraving Machines that are perfect for any project. Whether you’re a professional designer or just looking to add some personal flair to your paper products, these machines are the perfect tool for the job.

Coherent RF Metal Tube CO2 Non-Metal Laser Marking Machine

| Model | LS-CO2-100/150D |

| Laser Power | 100Watt 150Watt |

| Laser Generator | CO2 Metal Laser Tube |

| Laser Wavelength | 10.6μm |

| Engraving Line Speed | ≤5000mm/s |

| Repeat Precision | ±0.01mm |

| Minimum Line Width | 0.1mm |

| Minimum Character | 0.4mm |

| Marking The Maximum Height | 600*600mm |

| Power Supply | 110V-240V, 50Hz – 60Hz |

Large Size 3D Dynamic CO2 Laser Marking Machine for Paper Card

| Model | LS-CO2-250/300D |

| Max.Marking Area | 800x800mm |

| Laser power | 250watt, 300watt |

| Marking Speed | ≤7000mm/s |

| Power Consumption | ≤ 5 kWh |

| Worktable | Aluminum Honeycomb Worktable |

| Laser Source | Coherent CO2 metal RF Laser Tube Made in USA |

| Laser Wavelength | 10.6μm |

| Laser Frequency | 20kHz~200kHz |

| Scanner | CTI America |

| Repetition Precision | 0.01mm |

| Min.Letter Size | 0.3mm |

Features of CO2 Laser Cut Paper Card

- The wavelength of CO2 laser has a good absorption rate for paper card materials, so that the whole cutting process is more efficient, the laser system has higher stability and better cutting effect.

- For complex and fine designs, laser cutting can be easily realized, and the operation of the entire software system is more flexible and easy to use.

- Laser cutting is a non-contact process, which means that the paper card will not be deformed or twisted during the cutting process.

Laser Engraving Steps of Paper Card

- Design paper cards

- Prepare paper materials

- Setting up the laser engraver

- Perform laser engraving

Different Types Of Paper For Laser Engraving

These are just some of the available options, and the selection of a specific paper type depends on your specific needs and the power and material of the laser engraving machine.

Wood pulp paper

Cotton pulp paper

Composite paper

Copperplate paper

Common Problems And Solutions When Engraving Paper Card

Here are some common problems and solutions when using the Laser Engraving Machine for Paper Card:

- Poor marking quality:

It may be because the laser tube or mirror needs to be cleaned. You can fix this by cleaning or replacing them. - The marking speed is slow:

It may be that the power of the laser tube is insufficient or there is a problem with the mirror. You can fix this by adjusting the power or checking the mirrors for obstructions. - The marking position is not accurate:

It may be that the laser head is not correctly aligned with the origin. You can fix this by recalibrating the laser head and resetting the origin. - Smoke generated from marking:

It may be that the marking material is too thick or there is a chemical reaction. You can change the material or adjust the marking parameters to solve this problem. - Abnormal sound during the marking process:

It may be that the machine part is malfunctioning or needs to be lubricated. You can inspect and maintain the machine to fix this problem.

How to Maintain and Clean a Laser Engraver

Maintaining and cleaning your laser engraving machine is very important to ensure its long-term stable operation. Here are some suggestions for cleaning and maintaining your laser engraver:

- Clean the lens and laser head regularly:

Use a clean cotton cloth or swab to gently wipe the lens and laser head to make sure they are free of dust or dirt. - Change filters regularly:

The filters in your laser engraving machine keep dust and particles from entering the machine. Replacing the filter regularly keeps the machine clean and prevents it from malfunctioning. - Calibrate the laser head regularly:

When you find that the engraving effect of the laser engraving machine has deteriorated, it may be necessary to calibrate the laser head. - Replace fiber optics regularly:

If your laser engraver uses fiber optics, periodically inspect the fibers for fraying or damage, and replace those that need replacement. - Clean the work area regularly:

Regularly clean the dust and waste in the work area to ensure the cleanliness and safety of the machine.