ABS is used frequently in daily life. Products like phone shells, chargers, earphones, bottles, pens, are usually made by ABS, PC-ABS, PVC, PV, or other kinds of plastics.

Laser plays an important role in branding these products as being more attractive and exquisite.

A Belgium customer of Hispeed Laser, who is an electronic design house, gets benefits from the laser marking solution for their products currently.

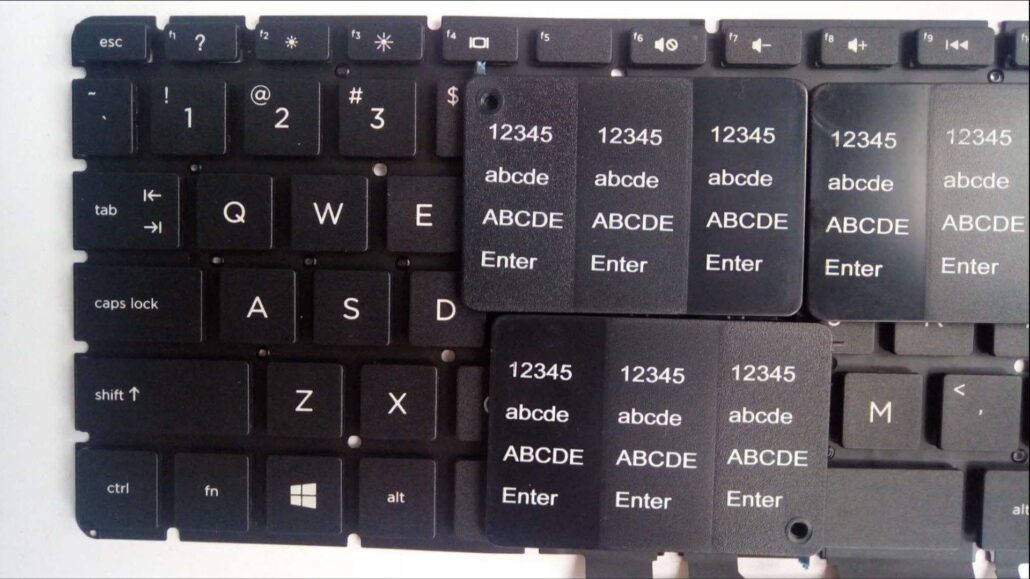

During the sample testing, we Hispeed Laser team tried both Fiber laser and UV laser.

Fiber laser marking on ABS material is good, but to this customer’s material, not as good as UV laser. Because UV laser shows a more fancy marking quality, no melting at all with smooth and delicate marking surface!

When customers received the samples, they found that the quality of UV Laser is better than Fiber. With confidence in us and our machine, they finally chose UV Laser Marking Machine for their product.

They are also very satisfied with the Hispeed laser team’s great communication and customer care service. It’s a pleasant purchasing experience for them.

That’s what we are pursuing, and thanks for the trust from all our customers and machine users.

By the way, besides ABS material, UV Laser can also do marking process on glass, ceramic, HDPE, PVC, PC, etc.

Welcome to contact us any time for consulting laser marking solutions for your products and sending samples to Hispeed Laser for a free laser marking test.