The laser marking machine/laser engraving machine for jewelry is a new generation laser marking system developed with the world’s most advanced laser. When it comes to jewelry, there is no doubt that they are an important part of our daily lives. Couples like to mark lover’s names or special dates on jewelry. People pursuing fashion …

Metal welding is a regular process. We need it for many purposes. Do you want to create tools, furniture, auto parts, kitchen utensils, construction buildings, or electronics? You will need welding in every place that involves metals. Among different types, a handheld laser welder is one of the most commonly used devices. People are replacing …

Welding is a critical process in metal parts manufacturing. It typically joins two separate metal parts. To do this, people use various methods. A Handheld laser welding machine and an arc welding machine are the most popular in the modern world. Many industries use this welding to produce parts, structures, and equipment. The core part …

Product labeling is an integral aspect of compliance with laws today. All products must have clear labeling with basic product information. However, manually tagging each product is time-consuming. That is why all businesses rely on automated solutions. An automatic laser marking machine is one innovative approach. An automatic laser marking machine can mark your product …

In factories, you often deal with hundreds of thousands of products daily. Each product must have appropriate labeling. Is it possible to mark all these products one by one? Of course not, especially in this fast-paced world. So, you will need an automated solution that can do this job quickly to meet your customers’ demands. …

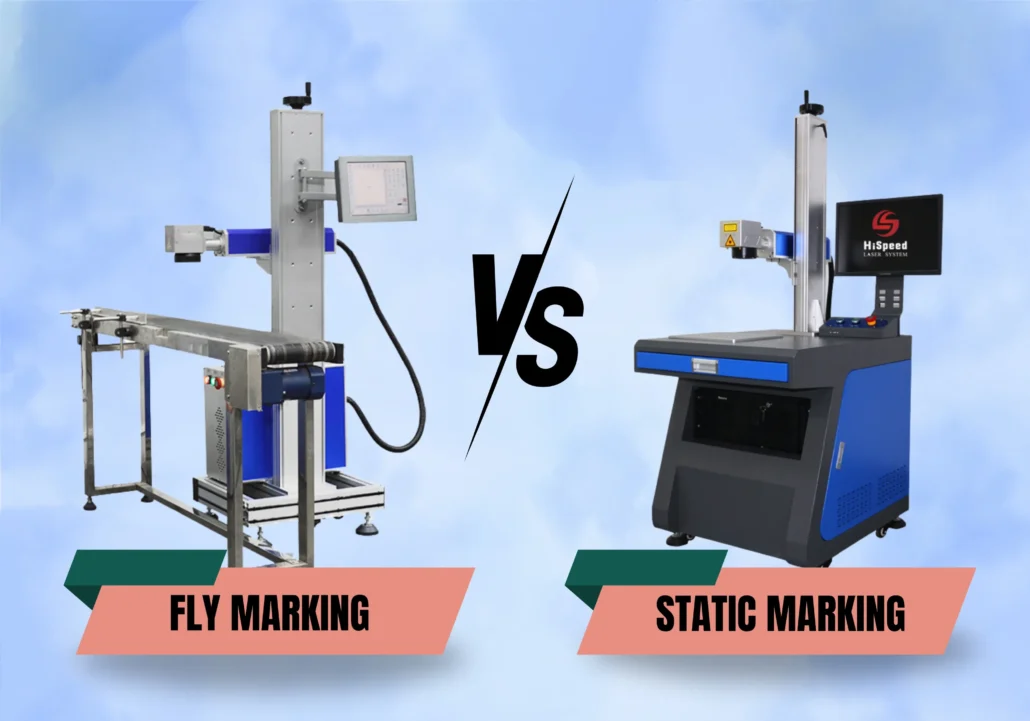

You may be familiar with laser marking machines. How do they work, and what are the different types? But when it comes to fly laser marking, many of us get confused. In this “fly marking vs static laser marking” guide, we will try to compare these two technologies. In which situation does this technology suit …

Have you ever wondered how a factory makes thousands of products? How do they produce markings on so many products in such a short time? Modern facilities, including the Conveyor Laser Marking Machine, make all this possible. Conveyor laser marking machines are one of the most popular automated marking solutions. They can label thousands of …

You might already be familiar with how laser marking works. It uses a laser beam to create marks on various objects, as usual. You can print text, designs, or pictures on different surfaces using this strategy. However, the type of laser marking may vary in this case, and fly laser marking is one of the …

Are you looking for the top 10 flying laser marking machine manufacturers? You’re not the only one! If you go out, you’ll meet many laser marking machine manufacturers. Each of them will claim to be the best in the lot. However, their performance may not support their claim. In such cases, one can easily …

Branding and carving names onto products have always been a trend. But have you ever wondered how a rigid metal tool can have a permanent mark on it? That’s possible with laser engraving! Laser engraver machines used to come in huge sizes, which posed difficulties for businesses due to space constraints. However, mini laser engravers …