Laser marking is one of the most popular methods for marking various types of material. People use it for different purposes. Creating décor items, logos, signage, glass etching, and product marking are some noteworthy examples. In factories, the use of laser marking is also increasing a lot. QR code laser marking is one of the most popular applications in product marking. Besides, marking barcodes, batch numbers, dates, and other product info is also noteworthy.

Why do people prefer laser gun engraving machines over traditional methods? In one sentence, laser marking is a fast, efficient, clean, and accurate process. Besides, this technology requires lower maintenance and is highly beneficial for long-term use.

Compared to traditional methods, QR code laser marking machines can complete every task quickly and with high precision. If you want to know more about it, read the whole article for a better understanding of QR code laser marking.

Overview of Laser Marking Codes

Among various marking methods, laser marking is the most accurate one. You can use a laser marking machine to create logos, product barcodes, QR codes, and even images.

With a focused beam, the machine creates a high-contrast, permanent mark. This remarkable outcome has become increasingly popular in product marking. As you are aware, product marking is an effective way to demonstrate your brand’s reliability. However, traditional methods such as painting, printing, or using stickers are not effective. Laser marking codes provide an advanced and permanent solution. Once marked, it is difficult to remove.

There are various types of laser marking codes. These are typically used to decrypt product information from just a single code. As you know, putting all the information on the product’s body is not a good idea. It is also not attractive. This QR code information-decryption method is quite efficient.

Laser-engraved QR codes, metal barcode tags, part numbers, and serial numbers are some popular examples of laser-marked codes. You can also create production dates, expiry dates, and other information.

What is the difference between Data Matrix, QR Code, and Barcode?

Data matrices, QR codes, and barcodes all serve to store and share information about products. But they have different sizes, shapes, and capacities for handling data.

A laser marking barcode is a type of one-dimensional code. This code can carry only a few characters and information. It features black lines, white gaps, and limitations in data transmission. This method is commonly employed in retail and packaging.

A laser-cut QR code is two-dimensional. Its shape is square and can accommodate various types of data, including URLs, contact details, numbers, and text. This method has a high overall capacity for storing information. It can easily maintain 4,296 alphanumeric characters. You can scan it with your mobile to get details about the products.

The data matrix is also a two-dimensional code. The code’s shape is rectangular. Generally, the shape is smaller than a QR code. For this reason, it can carry about 2,335 alphanumeric characters. As the shape is smaller and can hold less data than a QR code, it is suitable for marking on tiny items. It has significant applications in the electronics, medical devices, and aerospace sectors.

What is QR Code Laser Marking?

QR code Laser marking refers to the process of marking QR codes using a laser engraver. Similar to other laser marking projects, QR code laser marking creates codes on a product’s surface. The type of surface may vary depending on what kind of product you are dealing with. Thanks to laser technology, you can work with plastic, metals, glass, wood, ceramics, and many more materials.

The QR code holds up the entire dataset. This data can be website links, production dates, batch numbers, or any other product-related information. The advantage of a laser-etched QR code is that it is pretty clear, smooth, and durable. It cannot be easily removed or faded. As a result, you won’t have any trouble scanning these laser QR codes.

Laser-engraved QR codes are valid because they enable the identification of counterfeit products. Additionally, you may learn about customer support, safety, or product tracking. This method also helps you reduce cost and waste simultaneously. Ultimately, QR codes allow you to connect with the digital system.

Why QR Code Laser Engraving Machine?

A laser QR code engraver is the ideal device for creating durable QR codes. It offers multiple unique features for marking. Its versatility, precision, and efficiency are the main reasons for its widespread popularity. Moreover, the machine can work faster and provide a clean outcome.

Laser marking does not require any ink or other substances for the marking process. Instead, it uses a high-energy laser beam to create the mark without any physical contact. Thus, the beam creates a sharp, clean, and well-defined code that is easily readable by scanners. This way, the material will be far safer when you work with it.

On the other hand, traditional methods such as ink printing, chemical etching, and stickers have numerous limitations. Ink printing is prone to fading over time. Chemical etching uses acid solutions, which are not environmentally friendly. Also, chemical marking is ideal mainly for marking on metals. Additionally, stickers can easily peel off and sustain damage.

Considering all these drawbacks, the QR code laser marking machine will be the best choice for you. It is eco-friendly, gives a long-lasting result, and is a cost-effective process. This approach also minimizes the chance of material damage.

Recommended QR Code Laser Marking Machine

QR code laser marking can be of various types. HiSpeed Laser is a leading manufacturer of multiple types of laser engraving machines. Regarding QR code marking, laser markers can be divided into two types. One for marking only metals and the other for non-metals. Below, we will recommend the best machine on the market.

Metal QR Code Laser Marking

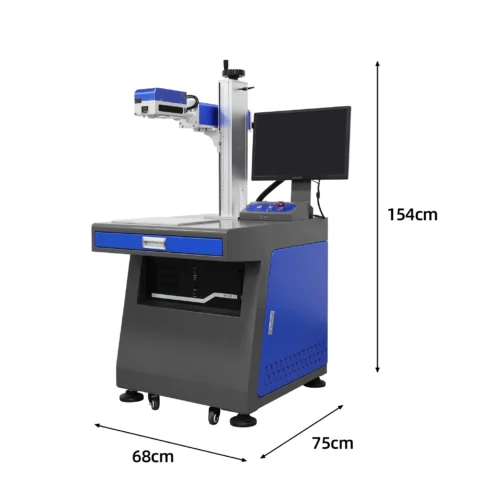

The HiSpeed fiber laser engraver, YLP-20L/30L/50L/100L, is best suited for marking. Each model of this QR code laser marking machine is capable of working on any metal. It works on fiber laser technology and a high-quality galvanic scanning system. You can customize the power as per your requirements. It’s a fast, easy-to-use, and high-precision working machine for mass production.

The technical parameters it offers include a wavelength of 1064nm. The marking range is 50 mm x 50 mm to 300 mm x 300 mm (optional). It provides a maximum line speed of 7,000 mm/s and a minimum line speed of 0.01 mm/s. The repeatability is ±0.01, which is a beneficial factor to consider, particularly in an air-cooling system.

Non-Metal QR Code Laser Marking

Mini LS-CO2 laser marking machine is suitable for marking non-metallic items. The machine features a well-maintained beam control system. It requires no maintenance and provides stable performance. You can use it in industrial work, from low to high volume, for speedy and high-precision production.

It supports high-resolution work with a resolution of up to 2540 DPI. Also, the cutting speed is 2-3 times faster than traditional methods. It boasts low processing costs, no consumable costs, and an energy-efficient process. Furthermore, it offers acceptable technical parameters. It would be the best choice for non-metal engravings.

For further information, contact us today. Start your journey with us and walk towards smart manufacturing.