Why choose our laser machine for cleaning?

- Easy setup & operation

- Eco-friendly process: No chemicals, media, or water required

- Zero dust pollution

- Auto-focus precision

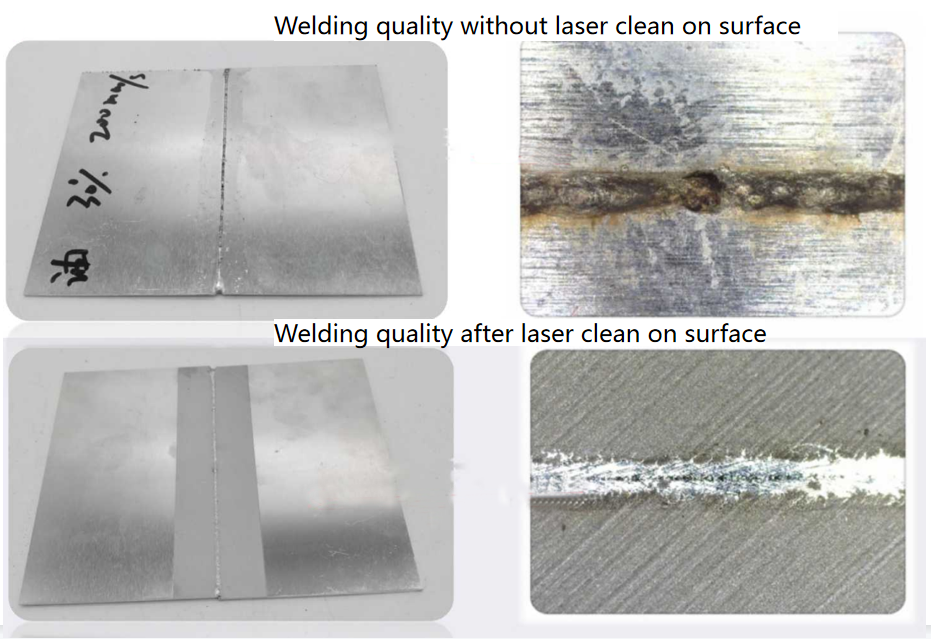

- Exceptional surface cleanliness

- Powerful laser rust removal capabilities: Effectively strips resin, oil, grease, rust, coatings, plating, and paint from surfaces.

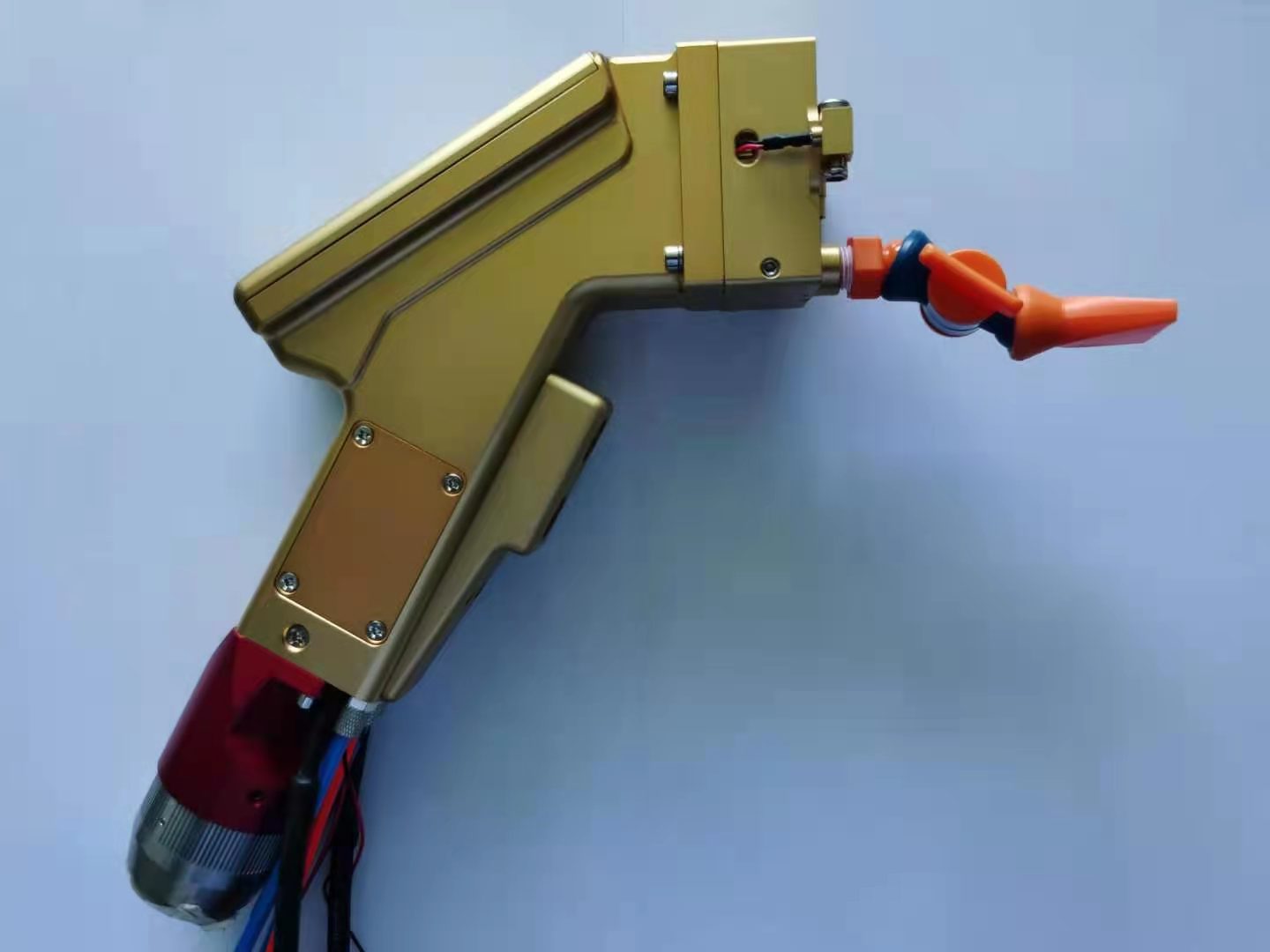

- Featured tool: Our portable laser rust removal gun excels on curved surfaces and complex geometries.

Ready to upgrade? Explore our high-performance cleaning laser machines today!

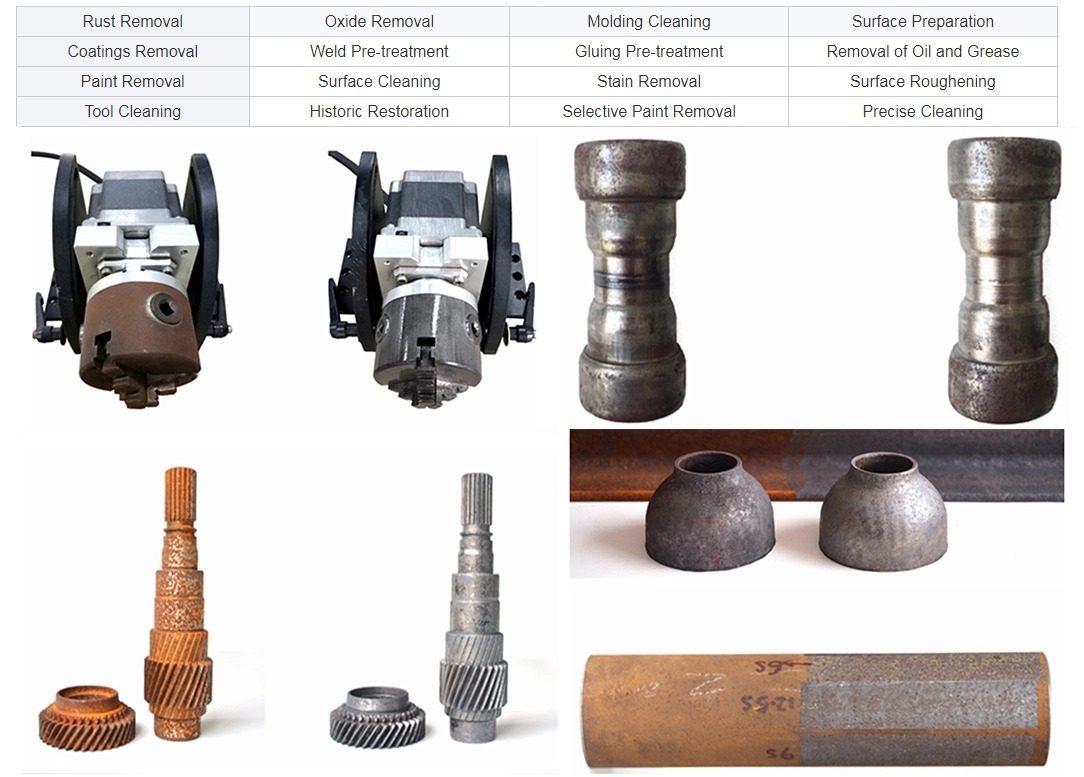

Applications for Hispeedlaser’s Laser Cleaning Machines

1. Metal & Industrial Restoration

- Remove coatings, rust, oxide scale & dry paint from metal surfaces

- Eliminate production residues: resin, grease, glue, dust, and dirt

- Pre-weld/glue preparation: Dry paint stripping, rust removal, degreasing

- Post-weld cleanup: Oil stain & adhesive residue removal

2. Mold Maintenance

- Precision cleaning of tire, electronic & food-grade molds

3. Precision Part Processing

- Degreasing precision components after machining

4. Critical Infrastructure Maintenance

- Nuclear power component decontamination

- Aerospace/shipbuilding oxidation treatment & rust laser removal

5. Specialized Surface Conservation

- Cultural relic restoration

- Architectural facade cleaning

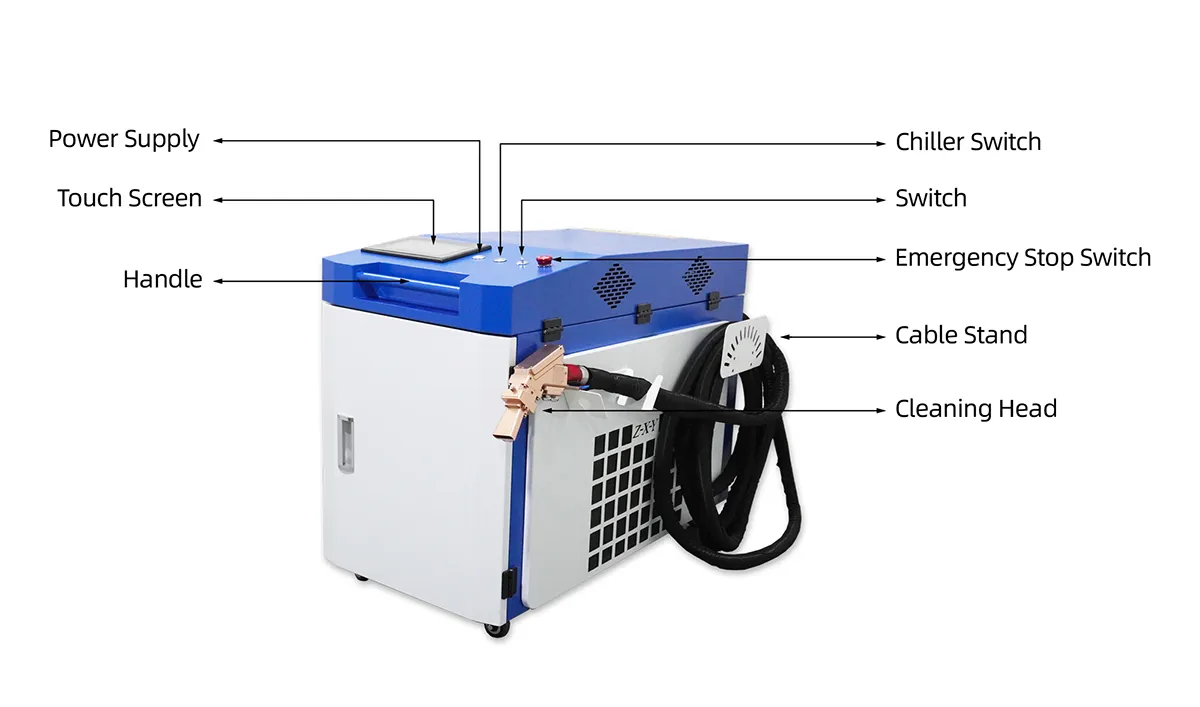

Laser Rust Removal Machine Parameters

Laser Rust Removal Machine Operating Environment |

|

| Content | Parameter |

| Supply voltage | single-phase 220V/110V±10%, 50/60Hz AC |

| Whole machine power consumption | 2500W (including chiller) |

| Place the environment | flat, no vibration, no impact |

| Working temperature | 0℃~40℃ |

| Working environment humidity | ≤80% |

Laser Rust Removal Machine Optical Parameters |

|

| Content | Parameter |

| Wavelength | 1080nm |

| Average laser power | 1500W / 2000W / 3000W / 6000W |

| Power adjustment range (%) | 10-100 (gradient adjustable) |

| Repetition frequency (KHz) | 20-50 (gradually adjustable) |

| Cleaning efficiency (m2/h) | 5 |

| Cooling method | water cooling |

Laser Rust Removal Machine Mechanical Parameters

|

|

| Content | Parameter |

| Machine Size |

450*950*800mm

|

|

Packing Size

|

107*61*85cm

|

| Net Weight | 110kgs |

|

Packing Weight

|

130Kgs |

| Fiber length | 10 meters |

| Cleaning head weight | 600g |

| Scan width | 10-100mm |

| Move method | Hand held |

Laser Rust Removal Machine Reference Sample

Hispeedlaser After-Sales Commitment: Your Partner in Laser Rust Removal Performance

🔒 Quality Assurance

Every laser rust removal machine undergoes rigorous inspection by our Quality Control team before shipment.

⚙️ Comprehensive Warranty

All cleaning laser machines include a 1-year warranty (excluding consumable wearing parts).

🎓 Expert Training

We provide in-depth instruction covering:

- Operating principles & system structure

- Safety protocols & maintenance procedures

- Software operation & processing techniques

💪 Proven Reliability

Industry feedback confirms our laser rust removal machines deliver exceptional performance with minimal failures.

🚨 Swift Support Protocol

Should issues arise, our response system ensures rapid resolution:

- 24-Hour Diagnosis Guarantee

Initial troubleshooting plan within one business day -

Dedicated Fault Analysis

Technical staff guide you through:Cause identification

Solution implementation

-

Remote Resolution Priority

Software/operational issues resolved online via:Screen-sharing (TeamViewer)

Video tutorials

Phone support

-

Continuous Digital Support

Access comprehensive resources:Technical documentation

Installation guides

Maintenance videos

Our Delivery Time and Packaging

Shipping time: 7-10 days after ordering

Transportation method: sea shipping or express delivery

Our machine successfully delivered to the customer

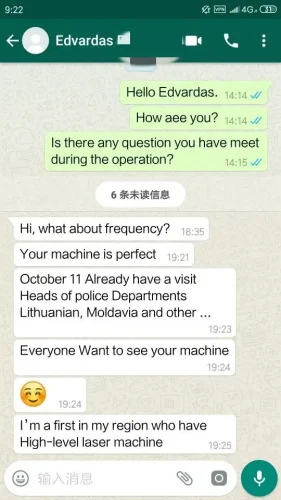

Feedback we received from customers

For more information, please contact us. We will reply you as soon as we receive your email.