Laser marking is one of the most popular tools for marking things nowadays. Its use in tech businesses is also no exception. Electronics makers use it to mark various electronic components. Why is laser electronic marking so popular? In a nutshell, it’s accurate, long-lasting, and highly versatile. It works on almost all types of materials.

Usually, a laser marking machine has a laser source and a laser gun. As the name implies, the laser sources produce the laser beams later projected by the laser gun. If you open the laser gun, you will find several mirrors. The purpose of these mirrors is to focus the laser beam at the correct location. The mirror moves according to the simulation program.

A laser marker is a common type of electronic marking machine. You can also refer to it as a laser e-marking machine. It is different from other e-markers. A laser electronic marking machine uses lasers to mark things other than paints or inks. You can use it to mark gadget cases, inner parts, wires, and more.

This method is safe and eco-friendly because you don’t have to touch the object. It is also computer-controlled, so you must correctly position the laser gun and monitor the process.

This article provides an overview of laser electronic marking. This guide will help you choose the correct device for your project in the future.

Various Uses of Laser Electronic Marking

Electronic devices can be made of different materials. Some are very heavy, while some are very thin. Heavy devices usually have metal enclosures. Good examples include ovens, motors, water pumps, and military gadgets. Thin devices are typically made of plastic casings. The electronic gadgets we use every day are noteworthy.

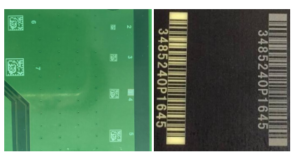

#1 Laser Marking PCBs (Printed Circuit Boards)

Nowadays, PCB manufacturers prefer laser marking technology over other methods. As said, laser marking is completely non-contact, which is a huge benefit when working on sensitive elements.

Laser marking uses a focused beam to create each mark with high precision and quality. It can be used to make serial numbers, barcodes, or logos. The marks you can create with them are high-contrast and durable.

On the other hand, laser marking doesn’t use chemicals, water, or other consumables. Therefore, marking on printed circuit boards (PCBs) does not risk damaging components. Besides, this technique is reliable for handling such delicate items.

#2 Laser Marking on Plastic Parts for Electronic Devices

Laser marking on plastic parts is the most common in the electronics manufacturing industry. It creates permanent marks on various plastic parts. People often use it to create logos or serial numbers. These permanent marks help customers identify the company and its authenticity.

Electronic marking is durable and strong, even if it undergoes rough or long-term use. It typically works well on plastics such as ABS, PU, or PVC. The best thing about laser marking is that it is a versatile method. You can customize the settings for different plastics, allowing you to use them confidently.

Many companies prefer this tech because it keeps each product looking professional and qualified. Occasionally, it also helps to track fake products. Typical examples are chargers, phone cases, laptop covers, remote controls, and many more.

#3 Metal Etched Electronic Components

Laser marking technology is also used to make metal-etched electronic components. It is a flexible method for creating precise and complicated computer parts. Indeed, laser marking technology plays a big role in etching these sensitive components.

Electronic devices have various metal parts, such as ovens, smart watches, AirPods, gaming consoles, and many more. Laser marking products can label these products without any contact. This allows you to mark these sensitive devices at a low cost and with high precision.

Considering other marking methods, you will see that each has disadvantages. For example, painting and printing are never durable. Stickers come off very easily, reducing the authenticity of the product. Dot peening damages the surface, making it unsuitable for use in electronics. The only solution to these problems is laser electronic marking. Although you may notice some limitations in terms of color, it is durable and more effective overall.

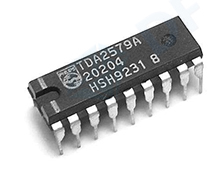

#4 Semiconductor Laser Marking

Laser electronic marking is also used to mark a wide range of small and delicate semiconductor parts. The industrial applications of semiconductors are evolving incredibly, so the demand for them will never end.

ICs, Microchips, packages, diodes, transistors, and more need proper labeling. You must follow various standards for it. Laser marking offers you a quick and reliable solution to do this. This way, you can ensure the safety of the product.

Popular Laser Electronic Marking Machine

HiSpeed Laser is a leading manufacturer of various types of laser devices. Their primary products include marking, engraving, and cutting machines. Some of their laser markers are highly suitable for electronic device marking.

You can choose between UV, Fly Online, and Fiber Online machines for laser electronic marking. Each of these machines is designed explicitly for electronic marking. As stated before, laser marking machines are very versatile. So, you will undoubtedly benefit from deploying them to various materials.

Mini 3D laser machines work excellently on flat, spherical, and multi-level surfaces. On the other hand, MOPA laser marking machines are quite famous for creating unique patterns. These patterns are usually created on jewelry, PVC pipe, stainless steel, and other surfaces. On top of that, CO₂ laser marking devices work great on wood, glass, ceramics, paper, leather, and other materials.

Expert Advice

There are specific points you should remember when marking electrical parts. For instance, laser beams can damage the sensitive elements used in electronic components. So, before buying a laser electronic marking machine, you should consider some factors.

- Firstly, think about the materials you are going to mark. Then, make a choice based on that.

- Accurate speed matters a lot during marking. Depending on your work requirements, choose high—or low-speed machines.

- An easy set-up and transition will greatly help you, so choose accordingly.

- Select a brand that offers a user-friendly manual, customer service, warranty, and easy maintenance.

- An appropriate budget is an important part, too. Sometimes, a slightly higher investment provides a long-term and reliable performance. Choose wisely before buying.

- Lastly, buy a machine with proper certifications and safety features for your team.

Contact us today to learn more. Our expert sales team is excited to answer all your questions. You can also explore our product pages to learn more about our capabilities.