Our Delivery Time and Packaging

Shipping time: 7-10 days after ordering

Transportation method: sea shipping or express delivery

Our machine successfully delivered to the customer

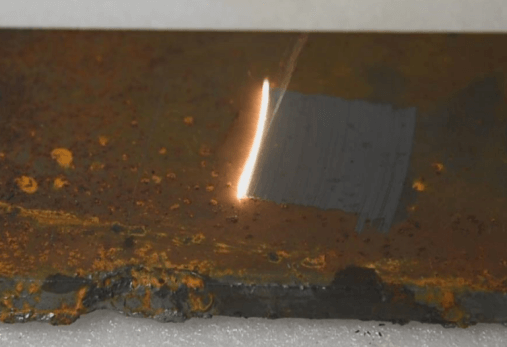

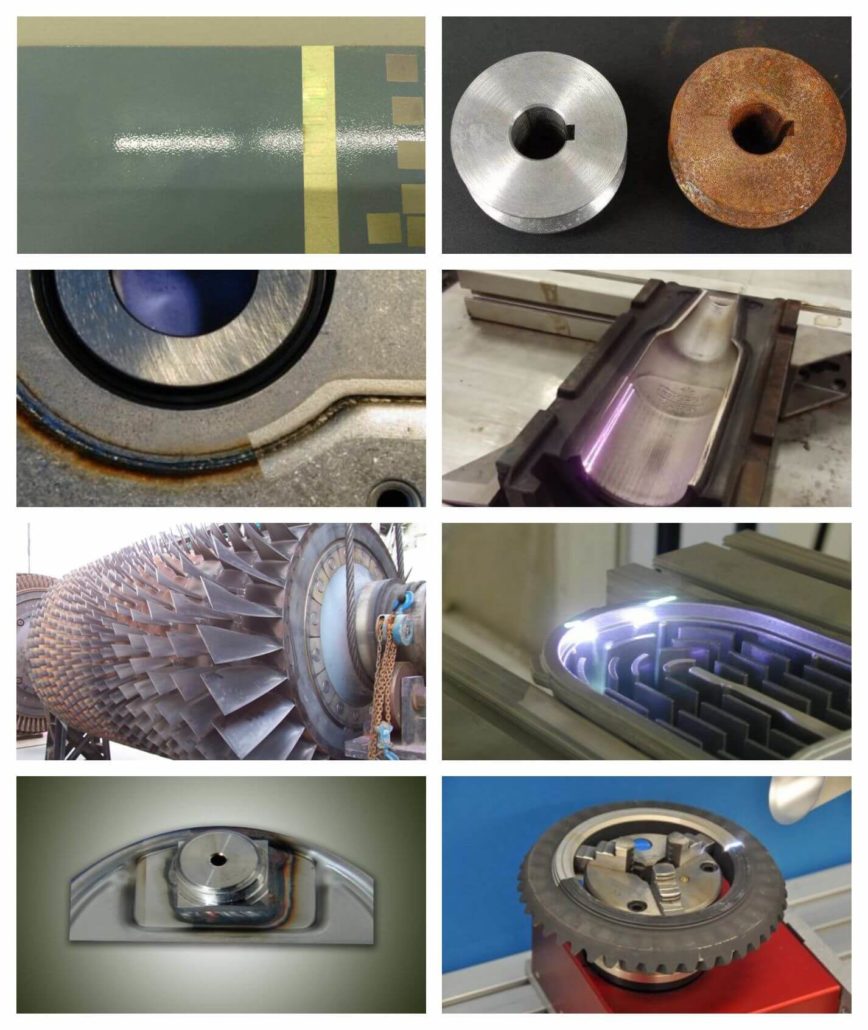

Our laser cleaning machine uses a laser beam to clean surfaces. It removes contaminants like paint, rust, and oxides.

Common Types:

CW (Continuous Wave) Fiber Laser Cleaner:

Uses a handheld head with continuous laser.

Cost-effective solution.

Ideal for removing rust or thin paint from metals like stainless steel, mild steel, and iron.

Power options: 1000W, 1500W, 2000W.

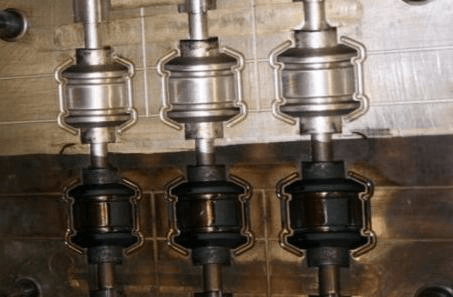

Pulsed Laser Cleaner:

Uses a galvo scanning head with pulsed laser.

Suitable for cleaning high-value items without damaging the base material.

Effective for removing oil, stains, and dirt from molds.

Power options: 30W, 50W, 100W.

| Content | Parameter |

| Supply voltage | 220V/110V/380V ±10%, 50/60Hz AC |

| Whole machine power consumption | 2500W (including chiller) |

| Place the environment | flat, no vibration, no impact |

| Working temperature | 0℃~40℃ |

| Working environment humidity | ≤80% |

| Content | Parameter |

| Average laser power | ≥1000W / 1500W/ 2000W |

| Power adjustment range (%) | 10-100 (gradient adjustable) |

| Repetition frequency (KHz) | 20-50 (gradually adjustable) |

| Cleaning efficiency (m2/h) | 5 |

| Focal length (mm) | 210/160 replaceable(with double red light pointer for focusing) |

| Cooling method | Water cooling |

| Comparision | Laser Cleaning | Chemical Cleaning | Mechanical Grinding | Dry ice cleaning |

|---|---|---|---|---|

| Washiing Method | non-contact cleaning | contact cleaning | Abrasive contact cleaning | non-contact cleaning |

| Harm to base material | None | Yes | Yes | None |

| Washing Efficiency | High | Low | Low | Mid. |

| Consumable | Power | Chemical Detergent | Abrasive paper, grinder, abrasive stone | Dry Ice |

| Washing result | Very good, very clear | Medium, uneven | Medium, uneven | Good, uneven |

| Precision Washing | Accuracy controllable. High precision | Uncontrollable, low precision. | Uncontrollable, medium precision. | Uncontrollable, poor precision. |

| Safety/Environment | No pollution | Chemical pollution | Dust pollution | No pollution |

| Operation | Easy to operate, portable or automation optional. | Complicated process, higher technical requirement of the operator. Pollution prevention measures required. | Need more time & manpower. Pollution prevention measures required. | Easy to operate, portable or automatic. |

| Investment | High investment on machine. But no consumable, low maintenance cost | Low investment on machine. But expensive consumables | Medium investment on machine. High man-power cost. | Medium investment on machine. High consumable cost. |

Shipping time: 7-10 days after ordering

Transportation method: sea shipping or express delivery

For more information, please contact us. We will reply you as soon as we receive your email.