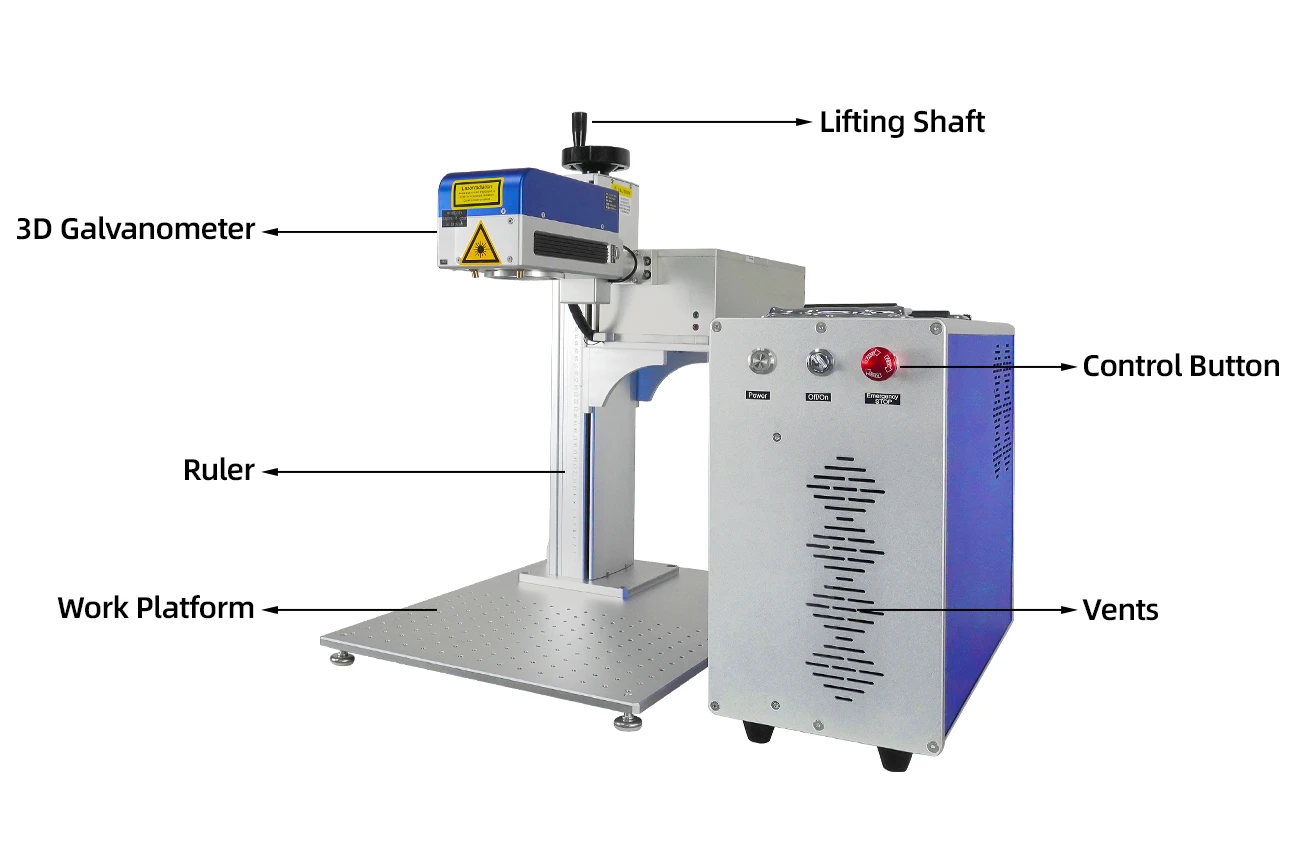

Product Description of Mini 3D Laser Marking & Engraving Machine

Mini 3D Laser Marking & Engraving Machine Details

Mini 3D Laser Marking & Engraving Machine Accessories

Mini 3D Laser Marking & Engraving Machine Technical Parameter

| Fiber 3D Scanhead (1064NM) | |

|---|---|

| Purpose | Marking and Engraving |

| Wavelength | 1064nm |

| Galvanometer | Dynamic Auto Focus 3D Scan Head System |

| Field Lens (MM) | Replaceable 70*70, 110*110, 150*150, 200*200, 300*300, 400*400 |

| Marking Depth | 0.03-0.5mm |

| Aperture | 10mm |

| The Diameter Of The Input Spot | 6.0~8mm |

| Dynamic Z-axis Speed | >1400mm/s |

| XY-Axis Scan Speed | >7000mm/s |

| Select Reference Table Of Focal Length Range Corresponding To Field Lens | ||

|---|---|---|

| Field Lens Range (MM) | Fiber | |

| Maximum Minimum Focal Length | Variable Focal Range | |

| 70*70 | 103~116 | 13 |

| 110*110 | 172~193 | 21 |

| 150*150 | 236~269 | 33 |

| 200*200 | 308~387 | 79 |

| 300*300 | 430~587 | 157 |

| 400*400 | 616~1017 | 401 |

| General Specification | |

|---|---|

| Working Temperature | 25±10℃ |

| Humidity | ≤75% Non Condensing |

| Power Supply | 110V-240V, 50Hz-60Hz |

| Size | 75*105*164 cm |

| Weight | 190KG |

| Cooling type | Air cooling |

| Operating parameter | 0-40℃ |

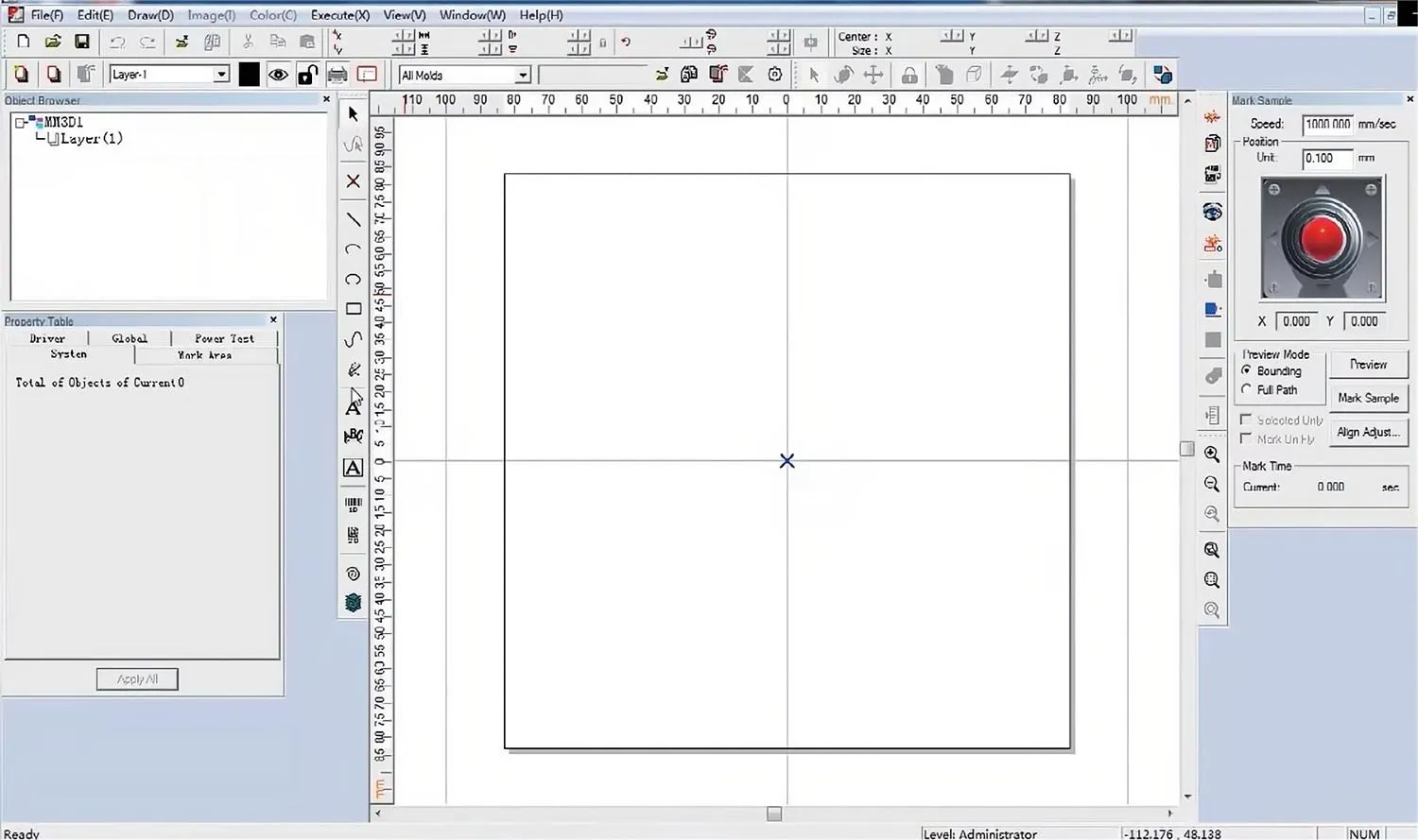

| Controller | Computer with marking software |

| Graphic Format Supported | JPG, BMP, DXF, PLT, STL |

MM3D Software Advantages

- Support STEP format files, STL3D model import.

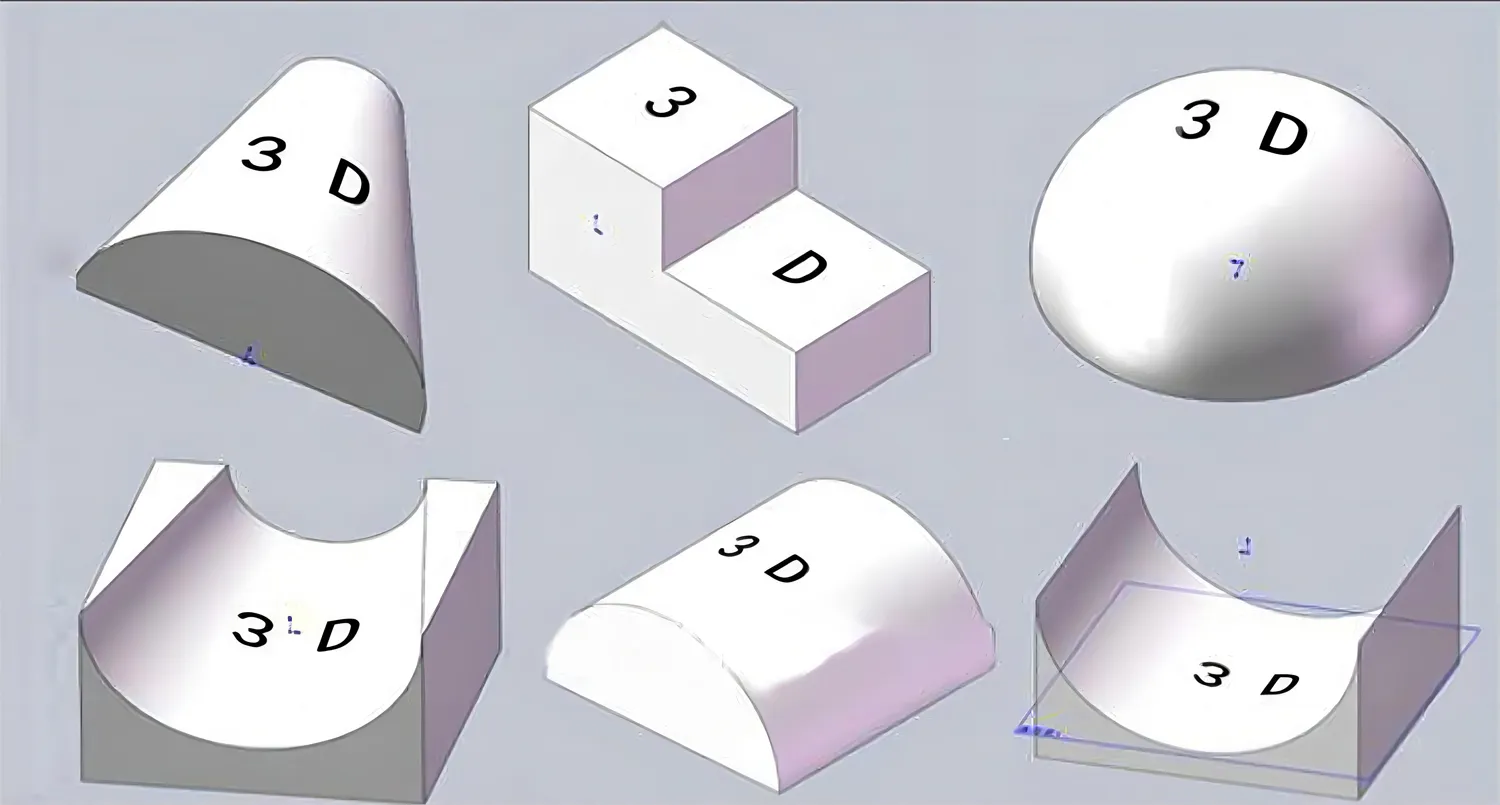

- Built in a variety of common surface models and 3D map slice deep carving function.

- Support import to 3d. DXF path; Support X, Y, Z axis control, automatic processing control.

- Extension to overlay or project images to 3D surfaces.

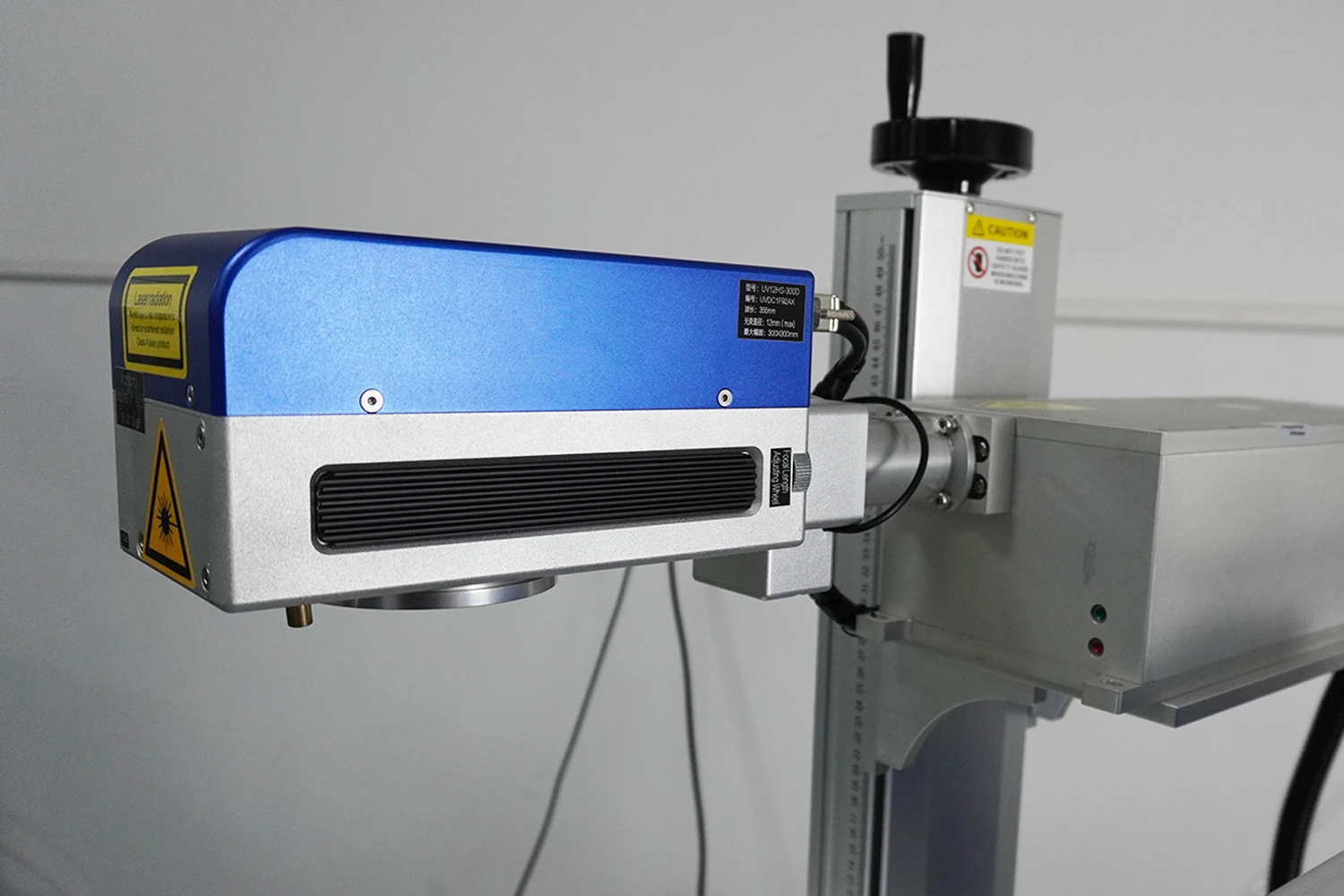

Precision 3D Galvanometer

- Using quartz lens material, effectively avoid power loss and field lens deformation.

- Provide precise lattice method correction lens, calibration file, ensure no distortion marking.

- The scanning speed is higher than 7000mm/s, meeting the requirements of high-speed on-the-fly.

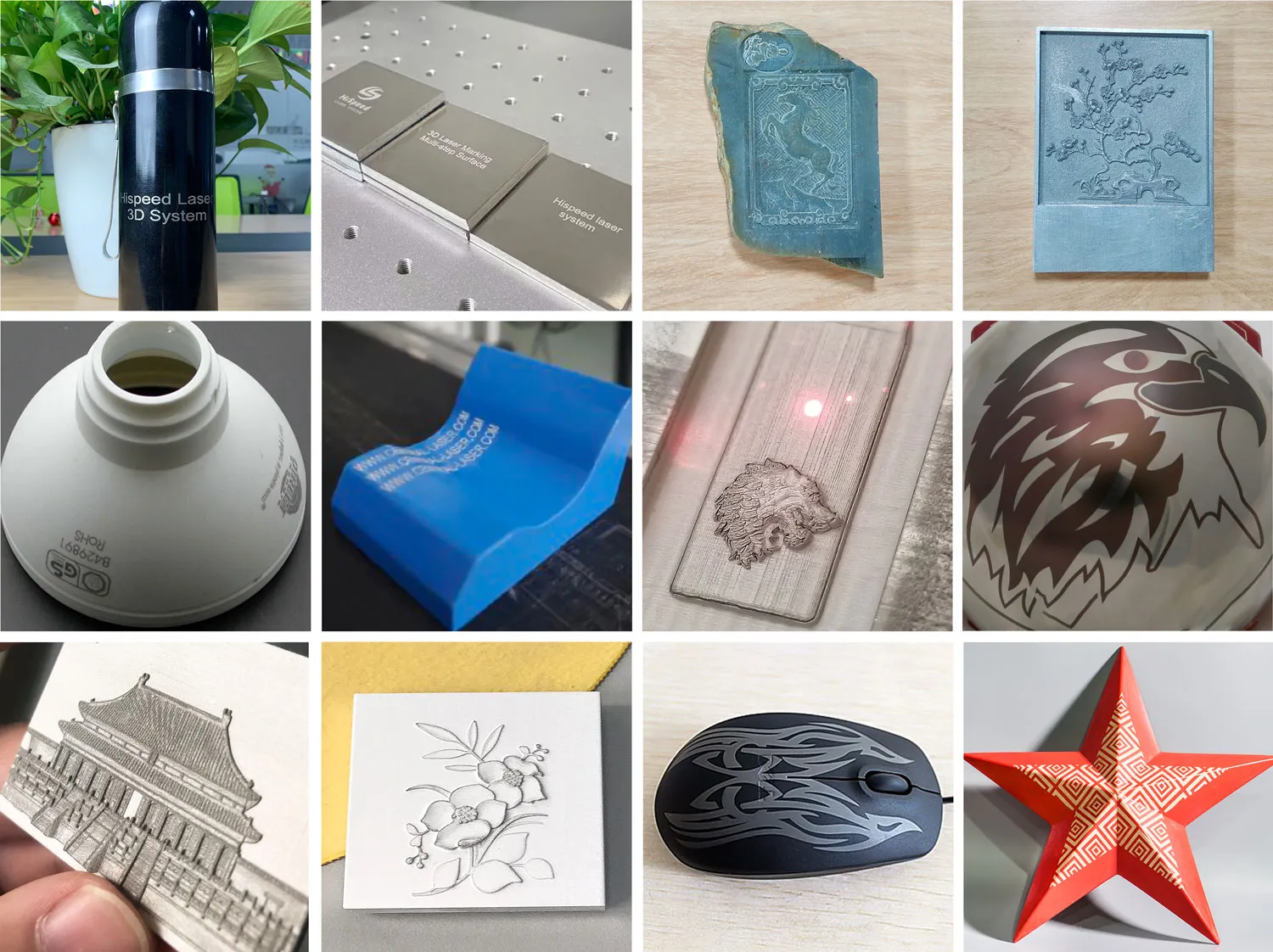

3D Laser Sample Display

After Sales Service:

1. All of our machines will be fully checked by our quality control department before the shipment. We guarantee all of our laser machines have a one-year warranty (quick-wear parts not included).

2. Training details: operation principles, system and structure, safety and maintenance, software the processing technique, and so on.

3. Numerous feedback from our clients has proven that our laser machines are stable in performance with rare malfunction. However, we would like to handle it as follows once malfunction occurs:

a.We guarantee that we will give you a clear reply within 24 hours.

b. Customer service staff will assist and guide you to analyze the malfunction in order to locate the cause.

c. If the malfunction is caused by improper operation of software and other soft faults, we will help solve the problem online.

d.We will offer plenty of online support, just like detailed technical and installation instructions by email, video, and telephone. (Training by team viewer)