Introduction of Fiber Online Flying Laser Marking Machine

The raycus 50w fiber laser machine can make dot matrices or scribbling laser encoding with high quality on fast-moving products and meet the demands of all kinds of production lines. This machine can mark letters, numbers, Chinese characters, icons, symbols, one-dimensional bar codes, two-dimensional bar codes, dates & times, serial numbers, random numbers, and other texts.

Raycus 50w fiber laser shipping display

50w laser marking machine acccessories

Raycus Laser Technical specifications

| Power | 20W/30W/50W/70W/100W |

|---|---|

| Wavelength | 1064nm |

| Beam Quality | M2<1.3 |

| Output Power | 10%-100%(continuously to be adjusted) |

| Output Frequency | 20KHz-100KHz(continuously to be adjusted) |

| Power Stability(8h) | <±1%rms |

| Focus Spot Diameter | <0.01mm |

| Engraving Speed | 800 standard characters/second |

| Minimum Line Width | 0.012mm |

| Minimum Character | 0.1mm |

| Repeated Accuracy | ±0.003mm |

| Cooling Mode | Air Cooling |

| Environment Temperature | 10ºC~35ºC |

| Environment Humidity | 20%-80% |

| Power Requirement | 220V/50Hz/or 110/60Hz |

| Life of Laser Module | 100000Hrs |

What is Mark on the fly?

Mark on the fly is continuous marking on moving parts. The parts are loaded onto a conveyor belt and automatically marked on that moving belt.This type of marking is used for continuous manufacturing processes where any standstill of the production line would be uneconomical.

Mark on the fly is used in 2D data logic, batch, date, and 1D bar-coding on FMCG packaging such as soaps, bottles, cosmetic jars, etc. A security number plate is a special application that is developed on this concept.

We proudly present international quality MOTF (Mark On The Fly) lasers at an affordable price. Components from France, Germany, Japan, and the USA ensure the system’s ultimate quality and long, trouble-free life.

Key features of this raycus laser at a glance:

- Customized solution.

- ITRACY integration.

- Metal sealed Co2 or fiber options.

- High performance.

- Options to use multiple heads.

- 24*7 hours duty cycle with outstanding beam quality.

- Excellent temperature control, bespoke lasers.

- High marking speed, easy to use & install.

- Flexible approach to design & engineering.

- Our Touch Control Marking Software is the perfect tool that offers various

- Possibilities to set parameters for marking objects & workpieces.

- Standalone functionality.

Raycus 50w fiber laser Key benefits:

- No consumables like inks, or cartridges.

- Marking on stationary and moving objects.

- Low maintenance cost, low wear, and tear.

- Compact, continuous, high-quality printing

- Marking on uneven surfaces and adjustable marking styles.

Raycus laser engraver Applications:

Marking on FMCG packaging goods and other sectors such as :

- Beverages

- Packing films

- Breweries & Distilleries

- Pharmaceutical & Medical Devices

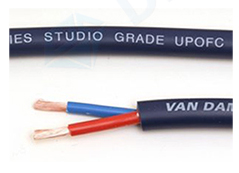

- Cable and wire

- Cosmetics

- Dairy

- Tobacco

- Automobile

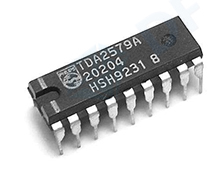

- Electrical & Electronics

- Holograms

- Labels

01. Galvanometer Scanner:

It is equipped with an automatic scanning system-friendly operation process. The laser head can be rotated 180″left and right. The whole marking system can be rotated 180°up and down. Support different angle marking.

02. Fiber Laser Source:

The machine is standard with a famous Raycus brand fiber laser source, with an expected 100,000 hours life span, support 7 x24 hours work, Other brand fiber laser source like MaX, JPT, and IPG are optional.

03 Standby Column:

With a ruler, wheels, and liting handle, easy to move and adjust the focal length.

04. Control System:

Sealed standby cabinet model control system, with USB port and wheels, support moving to any production line or table to mark.

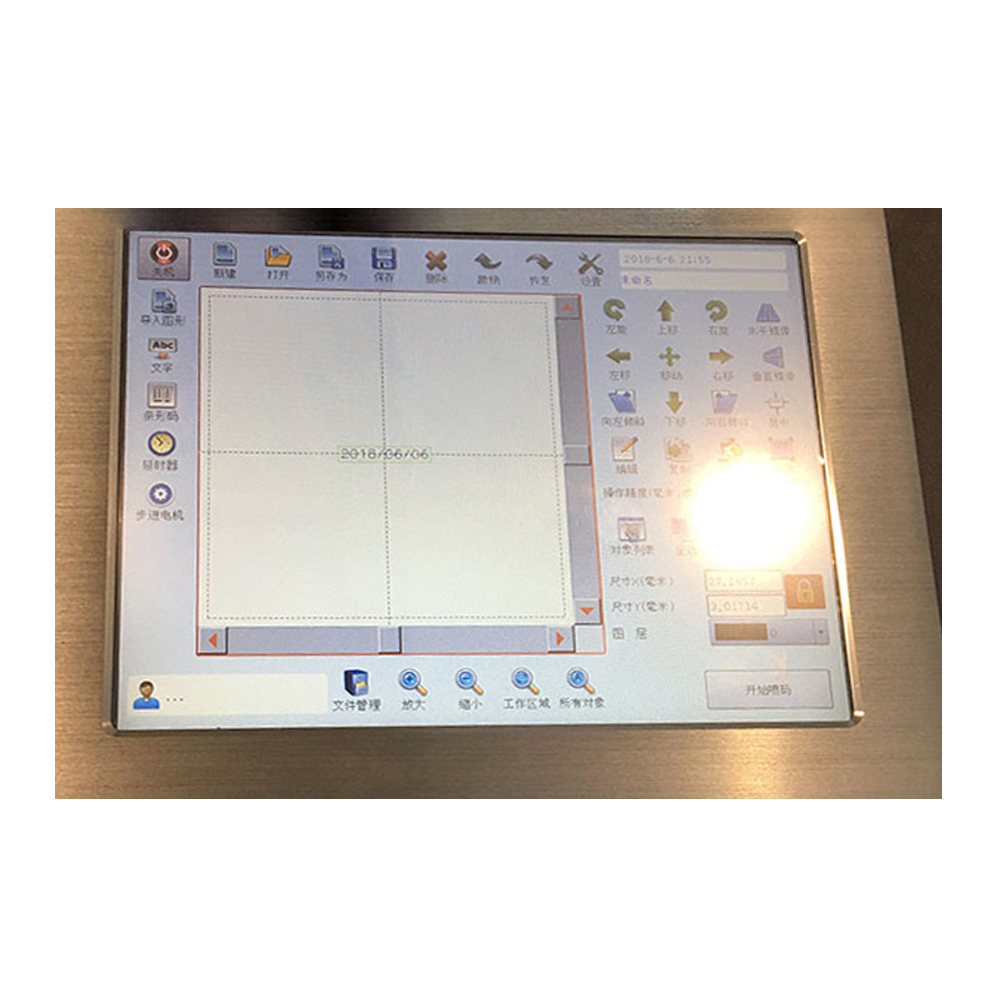

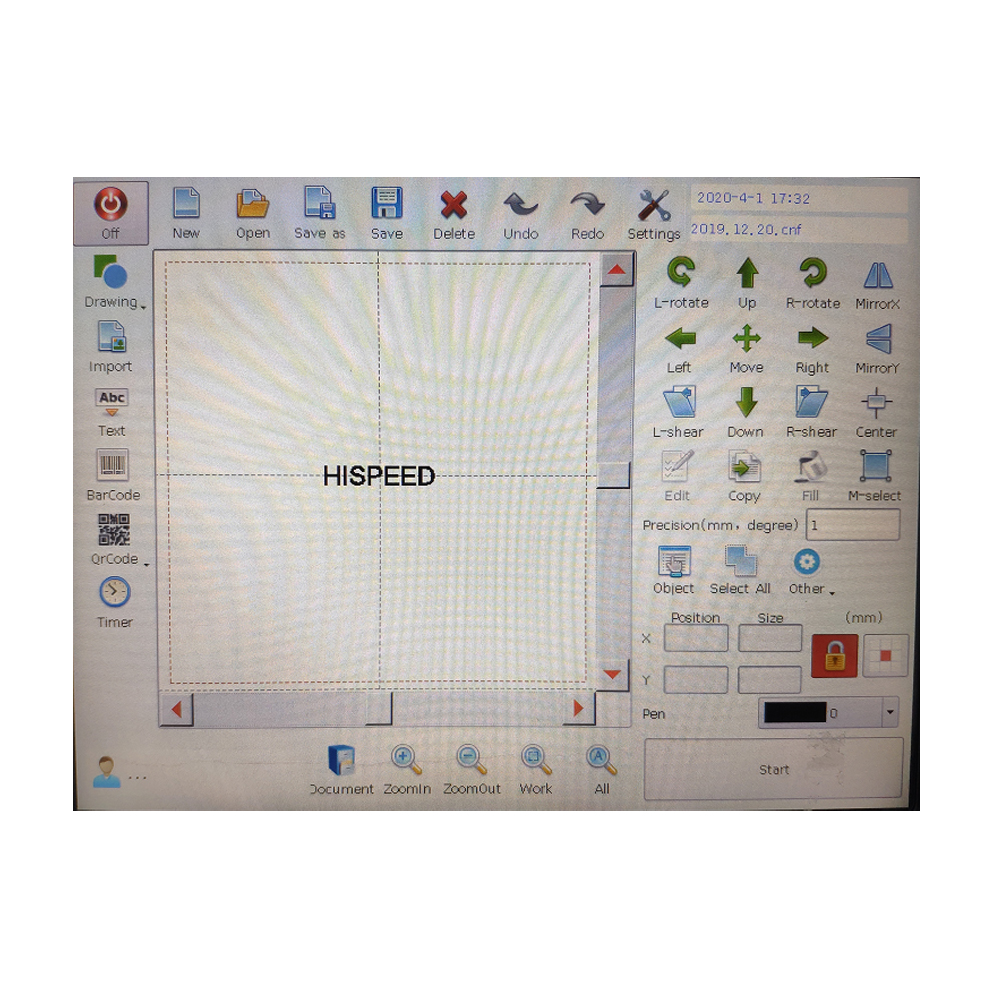

05. LCD Touch Screen:

LCD touch screen control panel, easy operation, no need to work together with PC.

06. Software:

Advanced marking software is already installed, especially suitable for production line mass marking, and easy operation.

Raycus laser engraver Industry Application

Electric Wire

Electron Component

Packaging Bag

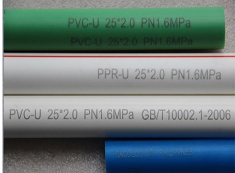

Plastic Pipe

QR code

Wire cable

After Sales Service

- All of our machines will be fully checked by our quality control department before the shipment. We guarantee all of our laser machines have a one-year warranty (quick-wear parts not included).

- Training details: operation principles, system, and structure, safety and maintenance, software processing technique, etc.

- Numerous feedback from our clients have proven that our laser machines are stable in performance with rare malfunction. However, we would like to handle it as follows once malfunction occurs:

a.We guarantee that we will give you a clear reply within 24 hours.

b.Customer service staff will assist you in analyzing the malfunction to locate the cause.

c.If the malfunction is caused by improper operation of software and other soft faults, we will help solve the problem online.

d.We will offer plenty of online support, like detailed technical and installation instructions via email, video, and telephone. (Training by team viewer)