| Laser Wavelength | 1064nm | 1064nm | 1064nm |

| Output Fiber Length | 10M | 10M | 10M |

| Maximum Laser Power | 1500W | 2000W | 3000W |

| Rated Power | 6KW | 7KW | 8KW |

| Power Configuration | 220V/50HZ | 220V/50HZ | 380V/50HZ |

| Light Spot Adjustment Range | 0.1-5MM | 0.1-5MM | 0.1-5MM |

| Laser Frequency | 1-10000HZ | 1-10000HZ | 1-10000HZ |

| Cooling System | Cw1000 | Cw1500 | Cw2000 |

| Aiming and Positioning | CCD, Red Light | CCD, Red Light | CCD, Red Light |

Worktable Parameters

| XYZ Travel | 500X300X300MM |

| Positioning Accuracy | 0.05MM |

| Repeatability Accuracy | 0.05MM |

| Maximum Moving Speed | 200MM/S |

| Worktable Size | 1300X1000MM |

| Optional Components | Servo / Stepper Motor, Rotating Axis, Extended Travel |

Innovation Highlight

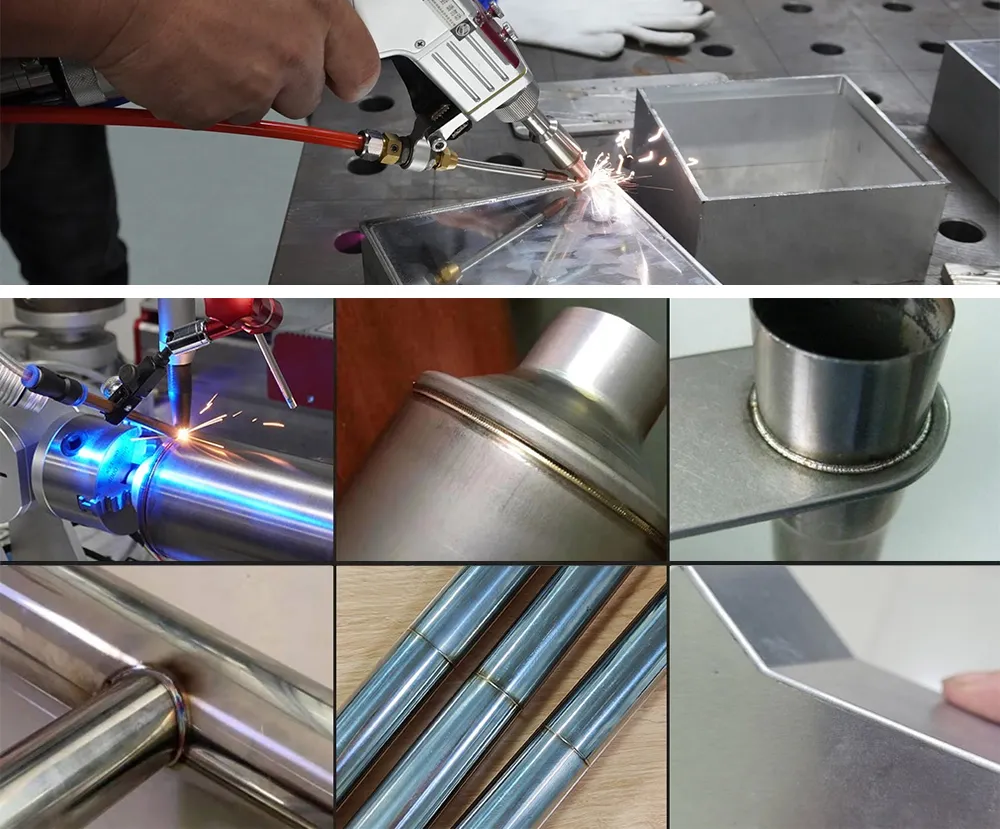

Our cutting-edge equipment is renowned for its rapid processing capabilities, deep weld penetration, minimal distortion, and the creation of visually appealing seam lines, all while maintaining low consumable requirements.

Our proprietary welding management interface is designed for stability and intuitive operation, simplifying the learning curve and ensuring ease of use. It supports complex programming for a variety of weld patterns, including continuous points, linear segments, circular paths, and curved trajectories.

By incorporating an electric positioning table, we have notably improved the accuracy of repetitive positioning tasks, which in turn has bolstered both the velocity of the welding operations and the overall processing pace.

Application Field

Our Fiber Laser Welding System is engineered for joining an assortment of materials with exceptional strength and quality, encompassing stainless steel, titanium alloys, aluminum composites, copper, and galvanized sheets. This system finds broad application across a spectrum of sectors, including electronics manufacturing, precision machinery, automotive production, household appliance fabrication, tooling industry, and metalworking, offering robust solutions for each.

After Sales Service

1.All of our machine will be fully-checked by our quality control department before the shipment.We guarantee all of our laser machines have a one-year warranty (quick-wear parts notincluded).

2.Training details: operation principles, system and structure, safety and maintenance, softwarethe processing technique, and so on.

3. Numerous feedback from our clients have proven that our laser machines are stable inperformance with rare malfunction.

However, we would like to handle it as follows oncemalfunction occurs:

a.We guarantee that we will give you a clear reply within 24 hours.

b. Customer service staff will assist and guide you to analyze the malfunction in order to locatethe cause.

c. If the malfunction is caused by improper operation on software and other soft faults, we willhelp solve the problem on line.

d.We will offer plenty of online supports, just like detailed technical and installation instructionsby email,video, telephone. (Training by team viewer)