There is no doubt that leather clothing is an essential part of our daily life. Nowadays, people keep pursuing fashion. The requirements of women for clothing are also increasing. Therefore, leather laser cutting machines and leather engraving machines are used in many industries. With a customized leather laser engraving machine, you can quickly provide quality finishes to leather, wallets, purses, bracelets, belts, shoes, etc. Are you looking for a suitable leather laser engraving machine for your company? Read this article to help you find a suitable leather laser cutting machine for your company.

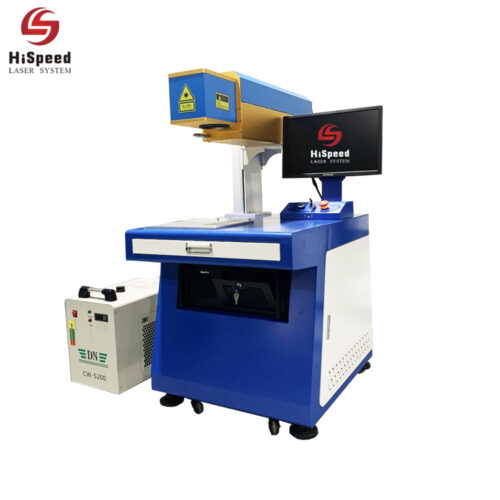

Some samples of Hispeed's laser engraving machine for leather:

Leather Laser Engraving Machine Working Process:

- Create leather laser engraving data or patterns on your design software Coreldraw

- Import the leather laser engraving design into Hispeed leather laser marking software

- Adjust the artwork accordingly

- Set marking parameters, such as speed, frequency, power, hatching method, etc.

- Test and adjust the parameters until the marking quality is perfect for you

Always observe the safety operation rules of the leather laser cutting machine. Start the leather laser engraving machine in strict accordance with the instructions for use

Advantages of leather laser engraving machine (leather laser cutting machine)

Marking on various non-metal materials such as leather, plastic, rubber, etc.

No consumables, maintenance-free (metal tube)

Stable performance of leather laser cutting machine, long working hours without deformation

Long service life, up to 60,000 hours

Fast marking speed, high efficiency, and high precision

leather laser cutting machine’s software has a powerful editing function but easy to operate

Types of materials suitable for various types of leather laser engraving machine

- Natural leather

- Cowhide

- Synthetic leather

- Suede leather

- Embossed leather

- Alcantara leather

- Wool

- cotton and linen

Please note that synthetic leather often contains PVC compounds. Such materials should not be processed with a laser. There is a risk of harmful gas emissions.

How to maintain the leather laser engraving machine

The best laser engraver for leather needs to be maintained after a period of use. The waste and dust generated during the engraving and cutting process will damage the engine. And will cause jams in the leather cutting process later, so should maintain the cutter regularly.

Lubricate the linear guide:

Turn off the power of the leather laser cutting machine and clean the guide with a clean, soft cloth. Then put a drop of lubricant on the guide rail of the laser cloth cutting machine. After oiling, let the slider roll back and forth on the guide rail to make sure the lubricant gets inside the slider. After oiling, let the slider roll back and forth on the guide rail of the leather engraving machine while slowly installing the guide rail. Note that we do not fix the guide rail first. We must finish installing all the fixing pegs first and keep the guide rail level.

Wipe the mirror and focusing lens:

After using the leather engraving machine for a while, smoke and dust will adhere to the surface of the lens. This will affect the depth of engraving and cutting of the leather engraving machine and its accuracy. We usually need to wipe the leather engraving machine carefully with absolute alcohol in a week to get three reflectors and a focusing mirror.

Oiling the bearings:

A laser engraving machine for leather uses many bearings to ensure good cutting and engraving results. We need to oil some bearings regularly by wiping off the floating dirt with a clean, soft cloth. Use a syringe to suck the oil into the syringe and then inject the applicability of the laser engraving machine for leather slowly with the needle. We need to rotate the directions slowly while oiling.

Timing belt (belt) tightness adjustment:

There are several timing belts in the drive system of the leather engraving machine. If the straps are too loose, the engraving will have heavy shadows. If the timing belt is too tight, it will cause the belt to wear out. So after the leather engraving machine is used for some time, please adjust the timing belt screws. We also need to change the belt to the proper tightness so that the leather laser cutting machine is straight during the cutting process.

Maintenance of laser tube:

The laser tube in the leather laser cutting machine is cooled by circulating water. After a long time of use, there will be some white scale in the box. We can add a small amount of vinegar to the circulating water to remove the gutter inside the tube. Then use clean water to circulate the laser tube inside clean so that the laser tube will be in the best working condition and extend its life.

The above is my summary for maintaining the leather laser engraving machine. I hope it will be helpful to you.