Features & Advantage:

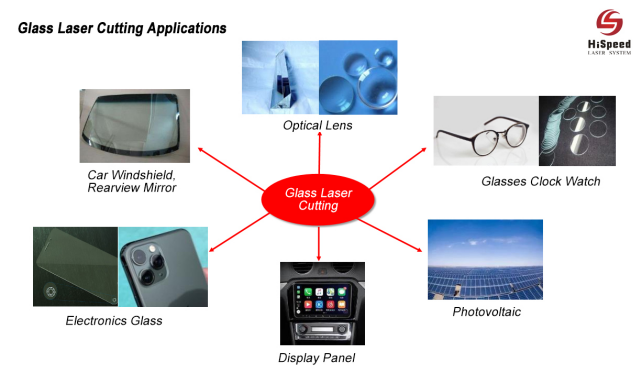

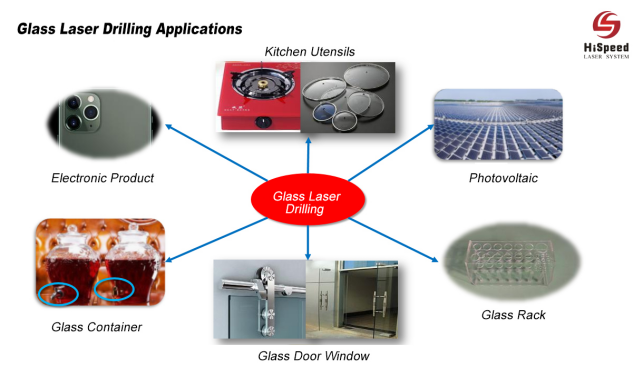

- Wide range of application

- No consumables, free Maintenance

- Water cooling design, stable performance

- High drillingspeed, high efficiency, high precision

- High single-photon energy

- Software with powerful edit function but easy operation

Applications & Materials:

- Glass Industry

- LCD Screen, Plasma Screen

- Thin Ceramic Marking

- Silicon Chips Marking

- IC Grain Marking IC

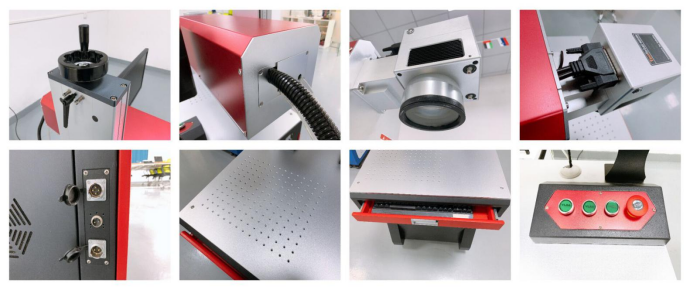

Machine Spares:

1.Laser Source – JPT M8 series(Lifetime upto 70,000hours)

2.2.5DGalvometer Scanning Head

3.Laser Marking Control Card and Software – Latest Version Ezcad with powerful edit function

4.Taiwan MW Laser Power Supply

5.Hispeed Laser – High quality F-theta Lens

6.Hispeed Laser – Industrial Computer & Screen

7.Hispeed Laser – Red Light Pointer

8.Water Chiller

9.Foot Switch

10.Deliver in plug & play state

11.Packing complying with the Export Packing Standard

12.Life-long after-sales service;Free consultation & guidance support

M8 Laser Drilling On Glass:

|

Drilling Diameter(mm) |

10 | 20 | 30 | 40 | 50 |

|

Glass Thickness(mm) |

Drilling Time(s) |

||||

|

1 |

1.9 | 4.0 | 5.7 | 7.8 | 9.7 |

|

2 |

3.0 | 6.4 | 9.8 | 14 | 19.8 |

|

3 |

3.5 | 8.0 | 11.8 | 24 | 32 |

|

4 |

4.8 | 9.4 | 14 | 28 | 40 |

|

5 |

6.1 | 12.3 | 20 | 32 | 46 |

| … | … | … | … | … | … |

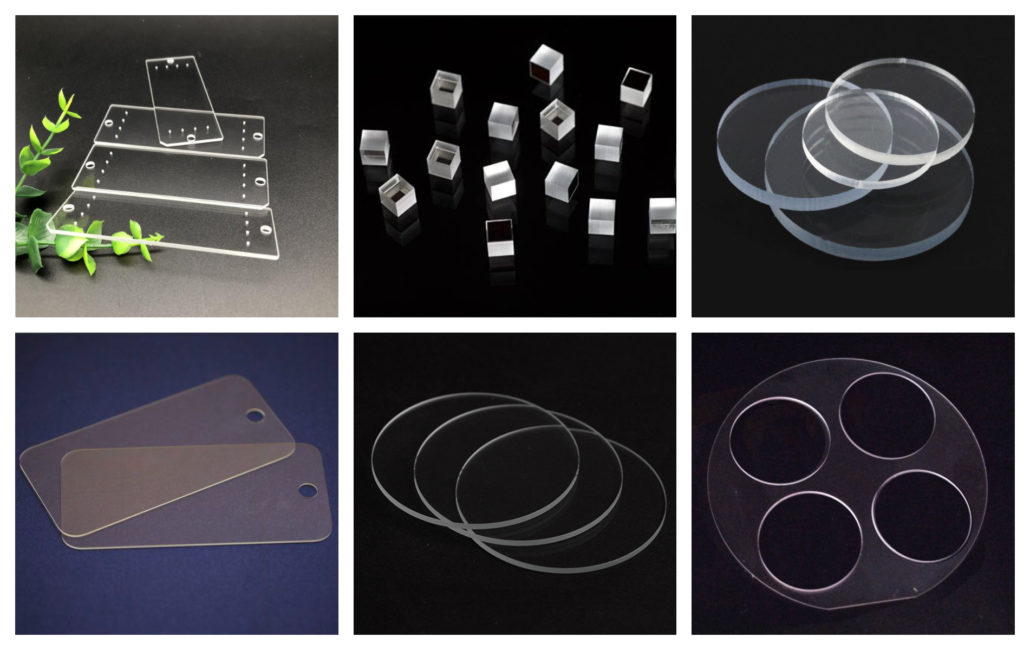

Sample Photos:

M8 Laser Drilling for Photovoltaic Industry:

Photovoltaic glass is usually ultra-white rolled glass with low iron content and special pattern treatment (enhancing the transmittance of light at different incident angles), so it has better light transmittance.

It is mainly installed on the outermost layer of photovoltaic modules to block the effects of moisture and corrosive gases, and protect cells and electrodes.

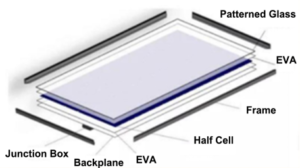

Schematic diagram of single glass photovoltaic module

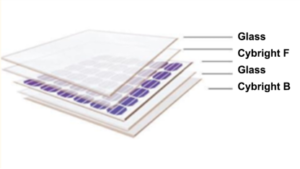

Schematic diagram of double glass photovoltaic module

After Service:

- All of our machines will be fully checked by our quality control department before the shipment. We guarantee all of our laser machines have a one-year warranty (quick-wear parts not included).

- Training details: operation principles, system and structure, safety and maintenance, software the processing technique, and so on.

- Numerous feedback from our clients has proven that our laser machines are stable in performance with rare malfunctions. However, we would like to handle it as follows once malfunction occurs:a.We guarantee that we will give you a clear reply within 24 hours.b. Customer service staff will assist and guide you to analyze the malfunction in order to locate the cause.c. If the malfunction is caused by improper operation of software and other soft faults, we will help solve the problem online.d.We will offer plenty of online support, just like detailed technical and installation instructions by email, video, and telephone. (Training by team viewer)