Although there are various types of marking machines such as co2 marking machines, desktop marking machines, fiber laser marking machines, etc. However, UV laser marking machine is still the best-selling one today. We prefer the laser UV marking machine because pharmaceutical packaging, tablets, credit cards, and other products require precision engraving.

But how do you choose a suitable UV laser marking machine, and what are its application industries? We will discuss these and more below.

Types of uv laser marking machine

EP Laser Marking Machine

Because the EP Laser Marking Machine uses a fully air-cooled laser, the entire working process is free of the risk of excessive temperatures reducing machine life. The laser has a wide adjustable frequency range and high photoelectric conversion efficiency. At the same time, to satisfy the demands of highly accurate goods, this UV laser marking machine’s output laser spot is smaller. The marking lines are more delicate, making it more ideal for more refined mapping and text marking.

Laser uv marking machine features

| Laser wavelength (Optical fiber) | 1064nm |

|---|---|

| Marking line width | 0.03mm |

| Minimum character | 0.15mm |

| Total powe | 500W-1000W |

| Marking depth | 0.01-0.3mm (Base on materials) |

| Repeatability | ±0.001mm |

| Optional marking range | 70x70mm-300x300mm(Standard150x150mm) |

| Cooling type | (Air cooling) |

| Size | 67x74x150cm |

| MODEL | YLP-EP10 YLP-EP15 YLP-EP20 |

| Marking speed | 100-3001mm |

Laser uv marking machine application:

- EP Laser Marking Machine can process cell phone keys, car keys, electronic audio keys, and other silicone materials.

- It is good at surface engraving without damaging the surface of the material

- The small amount of energy in the short pulse minimizes the thermal effect.

- Laser photoelectric conversion efficiency is greatly improved, up to 45% or more

- Consumes less power and reduces usage and maintenance costs

Precision UV Laser Marking Machine

Precision UV Laser Marking Machine is mainly used in industries that require extremely high precision. For example, we can use it in the pcb manufacturing and chip industry. The machine can use for cutting chip or semiconductor materials such as battery film, PI, EPC, or aluminum foil.

UV marking machine Technical parameter:

| Device model | SL-FC4540-NU15 | ||

|---|---|---|---|

| Laser source | UV 15w/20w/30w (optional nanosecond or picosecond) | ||

| Equipment station | Single optical path single station | Single optical path double station | Double optical path double station |

| Scan range | 54mm* 54mm (customizable) | ||

| Processing range | 650mm*550mm/350mm*500mm (customizable) | ||

| Precise positioning | |||

| Repeat accuracy | 士2μm | 士2μm | 土2μm |

| Depth control | ≤5μm | ||

Laser UV marking machine other features:

- High processing efficiency and stable operation.

- Automatic target positioning and CCD vision pre-scan, with a maximum processing range of 650mm*550mm. The splicing precision of the XY platform is 5m.

- Good cutting seam quality, minimal distortion, smooth and attractive look

- Advanced processing technology that can handle a variety of graphics tasks.

- Up to 7m minimum focus, suited for delicate cutting and drilling of organic and inorganic materials

- High precision and flexibility, including integrated CNC, laser, software, and other electronic technologies.

Desktop UV Laser Marking Machine

Metals, ceramics, composites, rubber, silicone, and a variety of polymers are all appropriate for this Desktop UV Laser Marking Machine. And it is mainly suitable for ultra-fine branding and engraving, such as on packing materials, medications, cell phones, keyboards, and chargers, among other things. They are also sometimes utilized in ultra-precise surgery. You can choose 3W UV laser marking machine, 5W, 8W and 10W.

Desktop UV Laser Marking Machine Technical Parameters:

| Model | LS-UV-3/5/8/10 |

|---|---|

| Power | 3W 5W 8W 10W |

| Wavelength | 355nm |

| Beam Quality | M2<1.3 |

| Output Power | 10%-100KHz |

| Output Frequency | <±2%rm |

| Power Stability(8h) | <±3%rms |

| Pulse to pulse instability | TEMoo(M2<1.3) |

| Spatial Mode | <2mrad(full angle) |

| Beam Divergence | 0.6±0.1mm |

| Beam Diameter | >90% |

| Beam Roundness | <50urad |

| Pointing Stability | H50rad |

| Polarization Direction | Horizontal |

| Polarization Ratio | 100:1 |

| Cooling | Water-cooling |

Desktop UV Laser Marking Machine other features:

- Stable and stable cooling system with an accurate internal temperature measurement system

- Application for ultra-fine marking and engraving

- Capable of engraving high-quality permanent marks

- Safe and environmentally friendly operation process, no harmful gas

- High photoelectric conversion efficiency and long service life

- UV laser marking machine prices are high

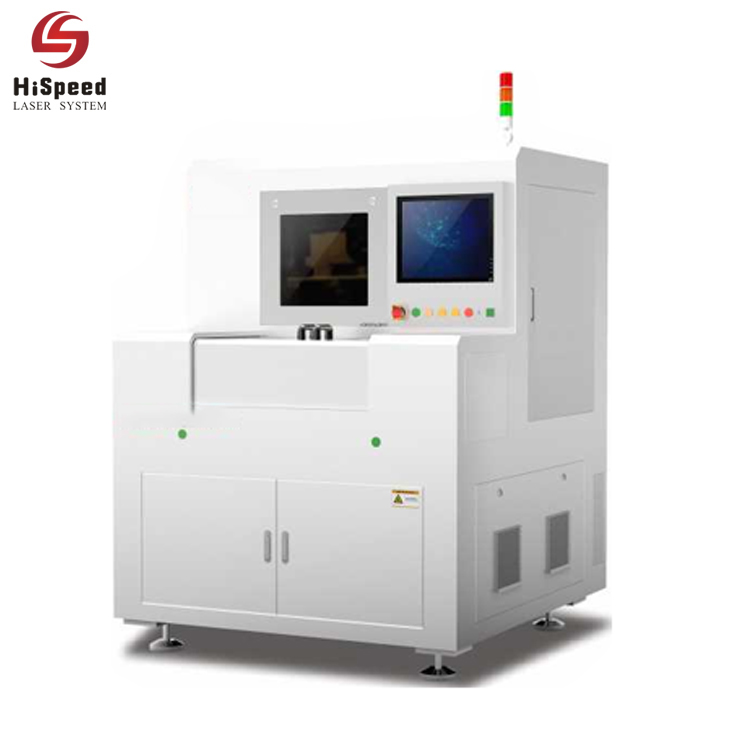

Full Enclosed UV Laser Marking Machine

The third-order intracavity frequency doubling (THG) technology is used in the 3W 5W 8W10W Full Enclosed UV Laser Marking Machine. Compared to the IR laser, the 355nm UV laser has a very narrow laser spot. This considerably lowers mechanical distortion and confines heat treatment effects to a small area. The Full Enclosed Laser Machine is ideal for ultra-fine processing in the high-end industry. Bottles composed of cosmetics, pharmaceuticals, foodstuffs, and other polymers, for example, are marked with pleasing results and firm marks.

Full Enclosed UV Laser Marking Machine Technical Parameters:

| Model | LS-UV-3/5/8/10 |

|---|---|

| Power | 3W 5W 8W 10W |

| Wavelength | 355nm |

| Beam Quality | M2<1.3 |

| Output Power | 10%-100KHz |

| Output Frequency | <±2%rm |

| Power Stability(8h) | <±3%rms |

| Pulse to pulse instability | TEMoo(M2<1.3) |

| Spatial Mode | <2mrad(full angle) |

| Beam Divergence | 0.6±0.1mm |

| Beam Diameter | >90% |

| Beam Roundness | <50urad |

| Pointing Stability | H50rad |

| Polarization Direction | Horizontal |

| Polarization Ratio | 100:1 |

| Cooling | Water-cooling |

Full Enclosed UV Laser Marking Machine other features:

- Material is removed by vaporization or ablation when the peak power density is very high.

- Reduces scum, splatter, and recasting.

- Allows for clean and precise machining without the need for finishing operations

Mini UV Laser Marking Machine

The Mini UV Laser Marking Machine is small in size and footprint, so it will expand well for use no matter how ample your space is. The Mini UV Laser Marking Machine runs at extremely fast rates, critical for short cycle times in industrial manufacturing. Due to their high repetition rate, high-speed UV laser marking devices with a wavelength of 355 nm are particularly appropriate for keeping polymers (such as ABS, HDPE, PC, etc.) in good condition.

Mini UV Laser Marking Machine Technical Parameters:

| Model | LS-UV-3 |

|---|---|

| Power | 3W |

| Wavelength | 355nm |

| Beam Quality | M2<1.3 |

| Output Power | 10%-100% |

| Output Frequency | 15KHz-100KHz |

| Power Stability(8h) | <±2%m |

| Pulse to pulse instability | <±3%rms |

| Spatial Mode | TEmoo(M2<1.3) |

| Beam Divergence | <2 mrad (full angle) |

| Beam Diameter | 0.6±0.1mm |

| Beam Roundness | >90% |

| Pointing stability | <50urad |

| Polarization Direction | <Horizontal |

| Polarization Ratio | 1900/1/4 4:01 |

| Cooling | Air-cooling |

Space Saver UV Laser Marking Machine

The laser UV marking machine from Space Saver is mostly used for ultra-fine marking or engraving. You can use it in a variety of industries for packaging marking, micro-hole marking, high-speed glass segmentation, and silicon wafer graphic cutting.

China UV laser marking machine Technical Parameters:

| Model | LS-UV-3/5/8/10 |

|---|---|

| Power | 3W 5W 8W10W |

| Wavelength | 355nm |

| Beam Quality | M2<1.3 |

| Output Power | 10%-100KHz |

| Output Frequency | <±2%rm |

| Power Stability(8h) | <±3%rms |

| Pulse to pulse instability | TEMoo(M2<1.3) |

| Spatial Mode | <2mrad(full angle) |

| Beam Divergence | 0.6±0.1mm |

| Beam Diameter | >90% |

| Beam Roundness | <50urad |

| Pointing Stability | H50rad |

| Polarization Direction | Horizontal |

| Polarization Ratio | 100:1 |

| Cooling | Water-cooling |

Factors that influence your choice of UV laser machine

- The material you want to mark: The laser machine you choose is mainly determined by the material you want to mark. As previously stated, different UV laser machines operate well on different surfaces.

- Budget: A modest and basic UV laser machine can suffice if your budget is limited. It can assist you with the basic chores of product labeling.

- Organization size: The size of your company is also a crucial consideration when selecting UV laser equipment. If you have a large organization that needs to mark a huge number of items in a short amount of time, it may require a more sophisticated machine.

UV Laser marking machine configuration options

- EP Laser Source

Hispeed branded, coherent Synard laser sources come standard with the unit. Machine life expectancy is 100,000 hours, and it can operate seven days a week. - Field Lens

The air gap design and anti-reflection coating on our tiny F field mirrors assure outstanding throughput and durability with less than 1% engraving distortion. - Galvanometric System

The laser’s high-speed Galvo-Tech digital oscillator mechanism lowers latency and speeds up engraving. - Operation Software

EzCad2 software is installed on our engravers and is compatible with Windows XP, 7, 8, and 10. The engraving program for professionals is solid, dependable, and simple to use. It can also use images from AutoCAD, CorelDraw, Adobe illustrator, Photoshop, etc.

Conclusion

We provide superior fiber laser equipment, closely monitoring every aspect of the machine. The machine parts are manufactured in-house, allowing us to maintain stringent quality control. Alloy, stainless steel, brass, aluminum, silver, steel, iron, and some non-metal materials such as ABS, PVE, and mold clone are acceptable for our UV laser marking equipment.