The fiber laser engraver does use in a wide range of applications. Fiber laser cutting machines can easily produce different wavelengths to cut metals and non-metals. They can also widely use in cutting, marking, welding, cleaning, texturing, drilling, etc. Fiber laser machines are ubiquitous in life.

What are fiber lasers?

Fiber laser cutting machines do create when fiber lasers are developed to be used as a solution. The fiber laser cutting machine is the tool that does the work, and fiber lasers are the framework for the integrated tool. The laser machine’s most basic applications.

- Laser safety and fume extraction ensure that workers are completely safe.

- Mechanical components are included to automate activities or make operator labor easier.

- Laser procedures are tailored to specific tasks.

The amplification medium of a fiber laser is an optical fiber core. They can compose of lanthanide rare earth elements in fiber optic cables. The fiber doping materials are chosen and doped into a glass fiber core that is ultra-pure. This enables the achievement of the chosen laser wavelength and power level. Fiber lasers are often utilized using ytterbium and erbium components.

Advantages of using fiber lasers

Fiber lasers are used in a wide range of industries, including automotive, aerospace, medical, jewelry, wood, etc. Next, we briefly talk about the advantages of a fiber laser engraver.

Compactness

The fiber laser cutting machine has a small footprint and compact structure. You can find the right size fiber laser cutting machine no matter how large your reserved area is. This is ideal in many environments where manufacturing space is at a premium.

Material Diversity

Fiber lasers can work with many different materials: metals including aluminum, iron, brass, stainless steel, titanium, etc., and non-metals such as glass, acrylic, rubber, etc.

Low cost

Fiber lasers are excellent for lowering costs. They are a cost-effective option with low maintenance expenses and a high return on investment. Fiber lasers are also more energy efficient than traditional industrial machinery. This helps to cut operational expenses while also reducing the environmental footprint.

What are the uses of fiber lasers?

1. The most significant benefit of a fiber laser is its high stability.

We normally require a fiber to safely move a laser beam when we want to emit one. Another option is to reflect it between mirrors, although this requires extremely precise alignment. The laser beam must be coupled to the tiny core of the fiber, which is difficult and requires delicate control. As a result, typical lasers are extremely sensitive to being knocked or struck, and once the optics are out of alignment, specialist categorization is required. On the other hand, fiber lasers generate the beam inside the fiber and transmit it without the use of complicated or sensitive optics. This makes it extremely stable and simple to operate.

2. The great beam quality of fiber lasers is the second reason they are helpful.

The beam can create and contain within a tiny fiber core. This means that the beam is exceedingly straight and may be focused on a very small point in practice. The smaller the point, for example, the better the laser cuts, but this quality is required for many laser applications.

3. Fiber lasers are becoming more powerful.

Fiber laserswith some topping 1,000 watts of output power (1kW). This is powerful enough to sever an inch of steel!

4. They are incredibly efficient and easy to cool, which is the fourth reason.

Other lasers may convert only a tiny portion of the power input, but fiber lasers can convert 70-80% of the power input from the pump source. Energy savings also mean that less energy is converted into heat. The fibers can very long, and the heat travels along the length of the thread, preventing it from overheating and breaking. When heated, almost all materials change their optical characteristics, affecting beam quality.

What types of fiber lasers are there?

The following characteristics can use to classify fiber lasers in general.

Laser power:

The material uses to blend the laser source influences fiber lasers. Because they produce distinct wavelengths. All of these lasers can employ for different applications.

The average laser beam power is measured in Watts. It does denote by laser power. You can have a 20W fiber laser, a 50W fiber laser, and so on. Lasers with higher powers produce more energy faster than lasers with lower powers.

Modes of operation:

The laser beam is released in various ways by different types of lasers. Pulsed fiber lasers, such as “q-switched,” “gain-switched,” and “mode-locked” lasers, can have their laser beam pulsed at a specified repetition frequency to achieve high peak power. They can also be continuous, which means that they can send the same amount of energy continuously (continuous wave fiber lasers).

Mode:

The size of the fiber core (where the light goes) in the fiber can refer to as mode. Single-mode fiber lasers and multimode fiber lasers are the two modalities. Single-mode lasers usually have a larger core diameter (usually between 50 and 100 microns), whereas multimode lasers usually have between 8 and 9 microns. Single mode lasers transmit laser light with higher efficiency and better beam quality. The average power of a beam of laser light is measured in watts. It does a 20W fiber laser, a 50W fiber laser, or a 50W laser.

There are many classifications of fiber lasers.

Please click on the following links to see examples of fiber lasers in products.

- Fiber Laser Marking Machine

- UV Laser Marking Machine

- CO2 Laser Marking Machine

- CO2 Laser Cutting Machine

- Fly Laser Marking Machine

- Mini Portable Laser Engraver

- Precision Laser Cutting Machine

- Laser Welding Machine

- Laser Cleaning Machine

- Ultrasonic Welding Machine

- Laser Consumables and Accessories

- Laser Smoke Purifier

What is the difference between a fiber laser and a CO2 laser?

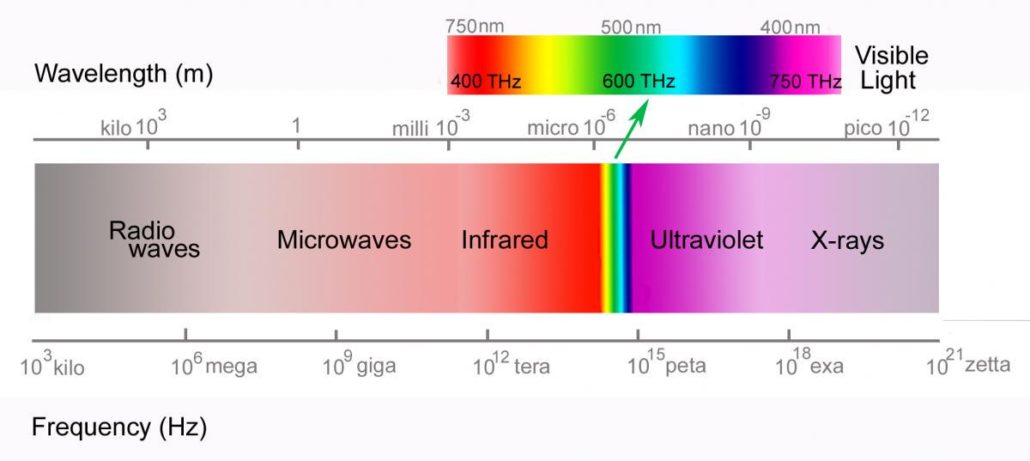

The source that produces the laser beam is the major distinction between fiber and CO2 lasers. Quartz glass and rare earth elements make up the laser source. The laser source of a CO2 laser is a gas mixture comprising carbon dioxide. Fiber lasers are classified as solid-state lasers due to the state of their source, whereas CO2 lasers do classify as gaseous lasers. Different wavelengths are produced by these laser sources. Fiber lasers, for example, produce shorter wavelengths, with some spanning from 780 to 2200 nm. Longer wavelengths can produce using CO2 lasers, which typically range between 9,600 and 10,600 nm.

They can employ for various applications due to their diverse wavelengths. Metal processing activities, for example, frequently use 1064 nm fiber lasers. Laser cutting is one notable exception, as CO2 lasers are typically better suited to cutting metals. Organic materials respond strongly to CO2 lasers as well.

What are laser parameters?

The parameters used by all lasers and laser applications are not the same. Laser cutting and laser marking, for example, require distinct adjustments. Some factors, however, are common to all-fiber lasers. Here is a list of the most likely scenarios you will encounter:

Image courtesy of the National Institute of Standards and Technology

Operation Mode

The manner in which the laser beam can release does know as the mode of operation. Fiber lasers usually operate in one of two modes: continuous wave or pulsed.

A continuous, uninterrupted laser beam release in continuous-wave operation mode. This is suitable for applications such as laser welding and laser cutting.

In the pulsed mode of operation, short pulses release at a specific repetition frequency. The higher peak power of the pulsed laser beam makes it perfect for laser engraving and laser cleaning.

The parameters for this model are as follows.

- Pulse Energy: This refers to the number of millijoules in each pulse. One pulse usually contains 1 mJ energy.

- Pulse Duration is the duration of each pulse. Also known as pulse width and pulse length. The unit measurement is milliseconds. Peak power is higher when shorter pulses concentrate the same amount energy in a shorter time. All units of pulse duration are microseconds to nanoseconds to picoseconds to femtoseconds.

- Pulse repetition speed: This is the number of pulses that can release every second. It can also call pulse frequency and measure in kHz. 100,000 pulses per second equal to 100 kHz.

Power

Laser power is the amount of energy a laser can produce in one second. “Average power” and “output power” are other terms for it.

Peak power, which is a separate parameter, can also indicate using pulsed lasers. A single pulse’s peak power is the amount of energy it can deliver. A 100W pulsed fiber laser, for example, can readily reach a peak output of 10,000W. This is due to the fact that, unlike continuous wave lasers, pulsed lasers do not evenly distribute energy across time.

Beam quality

The beam quality determines how near the beam is to a Gaussian beam. This is important in practical applications because it shows the degree of concentration of the laser beam.

A perfect beam quality is mathematically expressed as M 2 = 1. A well-focused laser beam concentrates more energy in a smaller area. Laser engraving and laser cleaning require a high-quality laser beam, although laser welding and other applications that do not require ablation may benefit from a lower beam quality.