The process of vaporizing material into the smoke to carve permanent deep marks is known as laser engraving. The laser beam operates like a chisel, eroding layers from the material’s surface to carve the mark. To achieve the high heat required for vaporization, the laser lights a localized area with a considerable amount of energy.

In this post, you’ll learn how laser engraving works and where to find a laser engraver.

From solid to gas: How fiber laser engraving works

While laser etching melts the material by increasing its roughness, laser engraving sublimates the material to generate deep fractures. This means that instead of becoming a liquid, the fiber laser engraving surface absorbs enough energy to shift from a solid to a gas.

Fiber laser engraving devices are practical tools, given the high temperatures required for sublimation. The laser engraving machine must generate enough energy to achieve sublimation. A fiber laser engraving machine heats the material’s surface to vaporization temperature in a few milliseconds.

| Material | Vaporization Temperature |

|---|---|

| Aluminum | 2327°C |

| Copper | 2595°C |

| Iron | 3000°C |

| Lead | 1750°C |

| Magnesium | 1110°C |

| Zinc | 906°C |

Source: “Corrected Values for Boiling Points and Enthalpies of Vaporization of Elements in Handbooks”

When the substance reaches this temperature, it will turn into smoke. Therefore, a fume extraction system and air knife should always include when purchasing a laser system. This will protect the working environment and the laser lens.

Since the 30w fiber laser engraver produces wavelengths that react well with metal, fiber laser engraving is a good tool for engraving.

3 common uses of fiber laser engraving

Fiber laser engraving machine has a wide range of applications. In fact, the majority of people who buy fiber laser engraving equipment do so with a certain purpose in mind, but they subsequently extend into other areas. Here are three of the most common applications for fiber lasers.

Bar Codes

For engraving barcodes and serial numbers on equipment and parts, we usually choose the best fiber laser engraver for the job. Fiber lasers produce high-quality markings that bar code scanners can interpret. You can serialize using a variety of code structures, including UPC codes, 1D codes, and data matrix codes.

You can utilize a laser engraver with a fixture to hold the individual pieces on the laser bed when serializing several parts. After that, serialize them all at once. The requirement for a dedicated operator to switch parts is eliminated.

Product / Business Logos

If you run a high-end product manufacturing company, etching your logo ensures that your brand is always visible to your customers. Because customers can remove labels voluntarily or involuntarily, laser-etched logos are preferable to printed labels.

Design

Fiber laser engravers can also use to create custom items. You may actually run a very profitable business as a laser engraver who specializes in specialized projects. And you may assist businesses and startups with engraving their logos on their items on a commercial basis. You can also sell personalized items like wall hangings, jewelry, and watches.

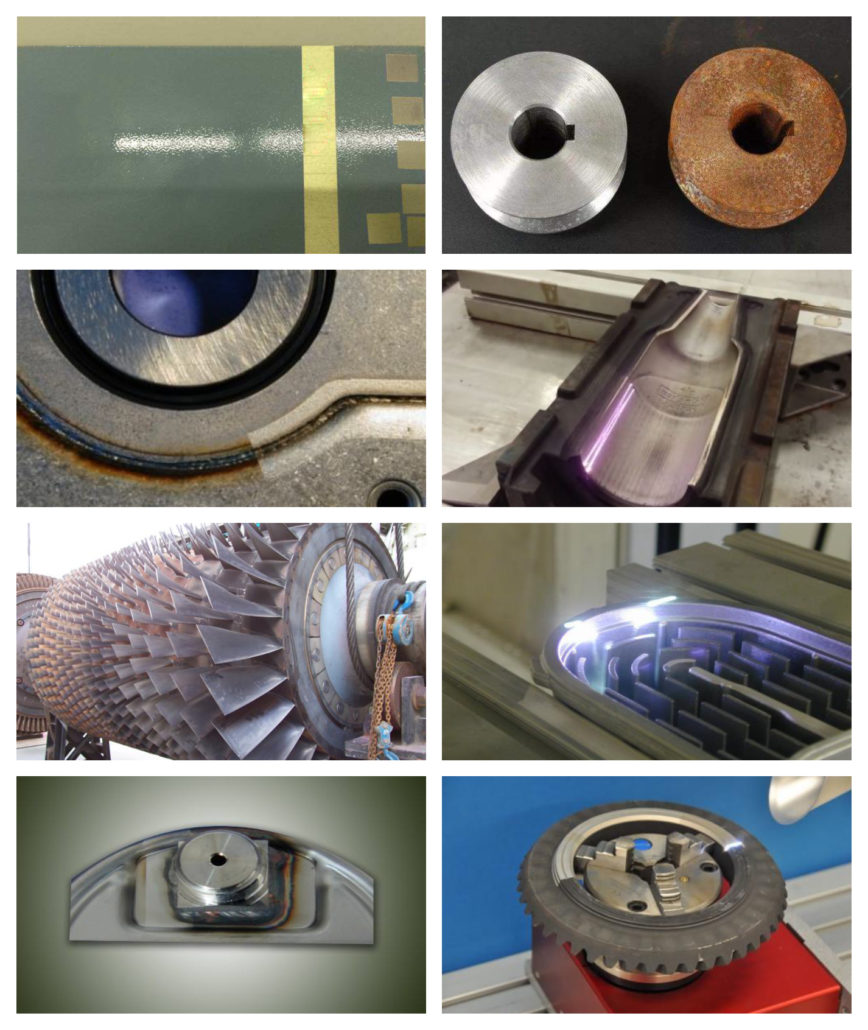

Fiber laser engraving machine for industrial applications

Automotive industry

Fiber laser engraving metal has grown very popular in the automotive business. There are approximately 35,000 parts in a vehicle. These parts are made up of various materials such as stainless steel, iron, and brass plastic. We can use fiber laser engraving metal to engrave precise sizes and styles.

The following are some of the applications that fiber laser markers are used to achieve part marking in the automotive field.

- Imprinting information such as country of origin, serial numbers, and bar codes on seat belt components.

- Labeling various dashboard components and buttons. During the day, they must be plainly visible, and at night, they must be illuminated. As a result, day and night marks are employed.

- These processes can also utilize to brand other materials, such as ceramics uses in spark plug manufacturing.

Engine blocks, vehicle sensors, chassis VIN numbers, and motorbike parts all include fiber laser markings.

Readability and traceability are two of the most serious challenges with marking in this business. The markings on parts should be machine-readable and traceable back to their country of origin. Fiber lasers have recently become more popular as a result of this.

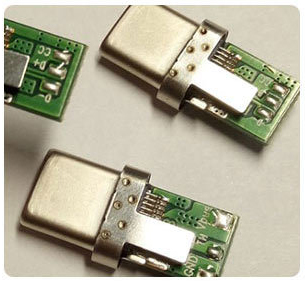

PCBs Industry

The most important units needed to build circuits and systems are pcb components. Integrated circuit boards and semiconductor components, as well as text and artwork, can be marked with fiber laser marking machines.

Mechanical tension is not generated due to the non-contact processing procedure. Since the laser beam is tiny, fiber laser engraving steel can integrate it into minuscule components such as capacitors and crystal oscillators.

Electronics Industry

In such a fast-paced profession, it’s vital to prioritize efficiency while meeting rising demand. Quality and safety are also expected in this need. Televisions, laptop computers, and smartphones are all made of microscopic particles.

Because of its capacity to handle small elements without destroying the surrounding material, fiber laser marking is the most efficient marking method in this business.

Medical Industry

The location, size, and content of markers are all strictly regulated in health facilities and medical device makers. Acid, corrosion, sterilization, and high-temperature cleaning are all requirements for markers.

Medical instruments may grow smaller and easier to use. However, the industry’s core priorities remain great quality and safety. Fiber laser engraver marking is growing popular in the business due to its high quality, cost-effectiveness, speed, reliability, and adaptability.

Jewelry Industry

Gold, silver, and other valuable stones can be marked with fiber laser machines.

To avoid forgery, the best fiber laser engrave can engrave its name or logo on jewelry. It is critical to maintaining this identity discreetly.

The jewelry industry uses the fiber laser for engraving because of its absolute precision, reliability, and lack of damage to neighboring parts.

Types of materials marked by fiber laser engraving machine?

As long as the materials are firm, brittle, and black in color, the best fiber laser engraver can work wonders on them.

This means that the laser can engrave most metals and some non-metallic materials. For example, a fiber laser can use to create high contrast marks on brass, stainless steel, and other materials. CO2 laser markers and fiber laser markers can both use on various materials, such as plastics. However, the outcomes are constantly variable, and the cost of various solutions must be considered. The materials that can be marked with a fiber laser are listed below.

Metal

Fiber laser engraver for metal can make the product more delicate and beautiful. Most metal engravings were done with fiber laser engraving steel in the past. This includes those used in jewelry, electronics, and other industries. Metals that can mark with fiber laser marking include the following.

1. Stainless steel

Steel is one of the world’s most often utilized metals. As a result, it is one of the most widely identified metals. Fiber lasers are the ideal marking method for steel because they combine speed, versatility, and reliability. Serial numbers, internal codes, and other markings on steel parts.

2. Aluminum

Fiber lasers use to engrave and mark aluminum because they produce clean high-contrast marks. It is capable of leaving these imprints on aluminum in a short amount of time.

3. Brass

Because of its great reflectivity, brass is a more challenging metal to brand. It usually reflects whatever is directed at it in this way. Because of its mechanism, fiber laser technology is an excellent solution. It must run at high peak power to obtain the desired results.

Gold, platinum, iron, aluminum, and silver are some of the other metals that have been employed in various industries.

Plastics

Plastic is a non-metallic material that is often utilized in this marking technology.

We use fiber laser engravers in a variety of industries, including automotive, food and aerospace, as well as consumer electronics and medical. Plastics require smooth, unambiguous marks for a variety of reasons, including identification and tracking.

These markings can see on finished goods, bar codes, and traceability labels. Food-grade plastics that are added before labeling are a nice example of labeled plastics.

Fiber laser marking of plastics can only work on common plastics such as PVC, PE, ABS, and other common plastics from producing technical plastics through the finished product.

Carbon fiber

This material is usually easy to mark with fiber laser markers because the result is always black.

Should you choose laser engraving or laser etching?

We use several processes for various purposes. When we’re torn between engraving and etching and can’t decide which is better. We must examine the following three factors:

- Marking resistance: the ability to maintain clarity under harsh conditions

- Laser marking speed: marking time to prevent production bottlenecks

- The material being marked: compatibility with the marking method

Metal items that are susceptible to various sorts of wear and tear or surface treatments are frequently engraved using laser engraving technology. Steel and aluminum are both excellent for metal engraving (including anodized and die-cast aluminum).

Fiber Laser Engraving of 2D codes

The capacity to engrave 2D codes is the most impressive aspect of the fiber laser engraver marking procedure. After fiber laser engraver treatment, it can maintain the high readability of the item. To handle the most difficult traceability challenges, these treatments can involve shot blasting, e-coating, and heat treatment.

Laser etching is generally preferred when the most corrosion-resistant identification does not need to be engraved. This is due to the fact that it is a quick approach that does not rely substantially on ablation. Steel, aluminum, anodized aluminum, lead, magnesium, and zinc are among the materials that can be laser etched.

Laser annealing is another unique approach for marking metals like stainless steel.