Product Description

Features

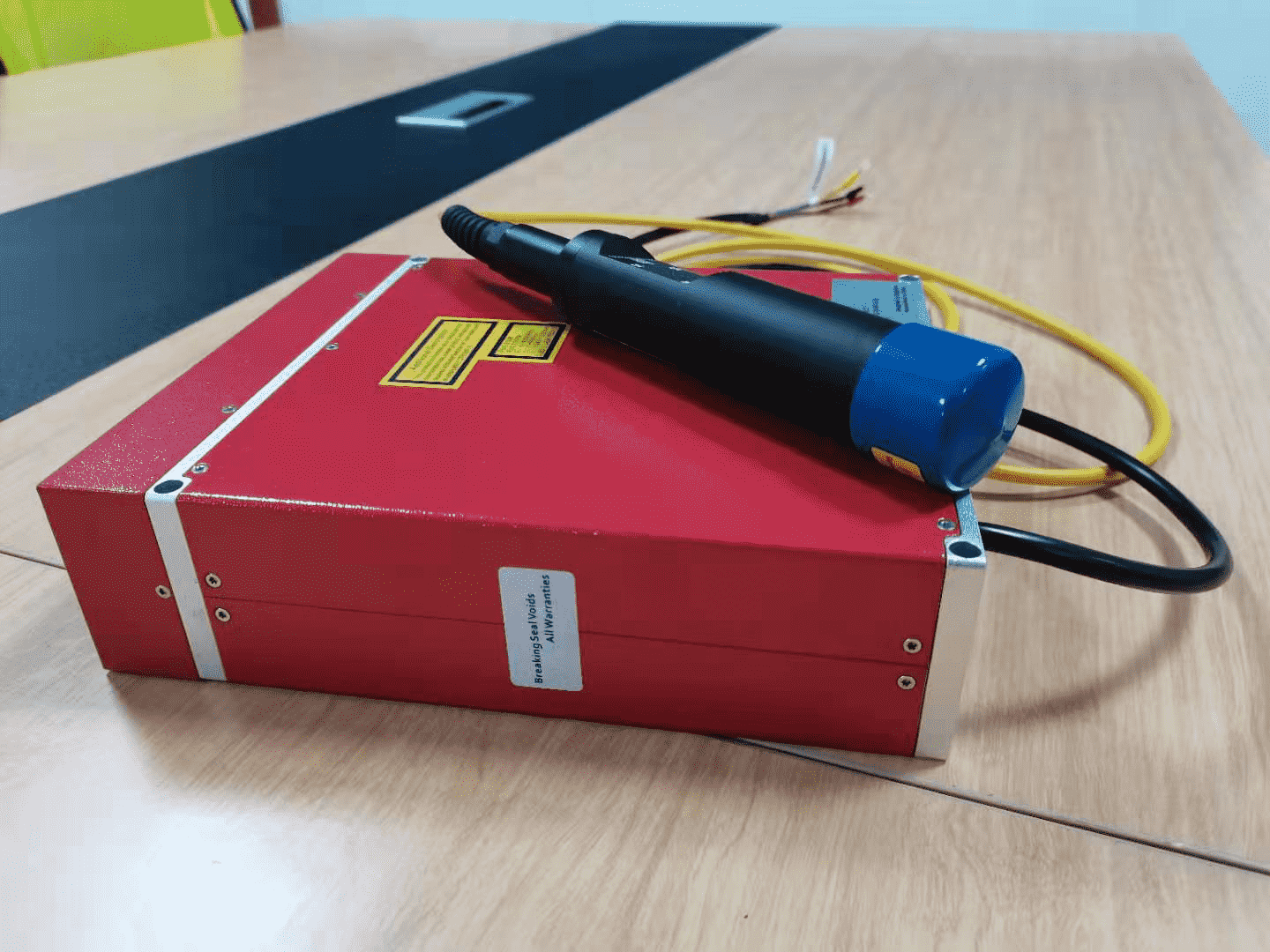

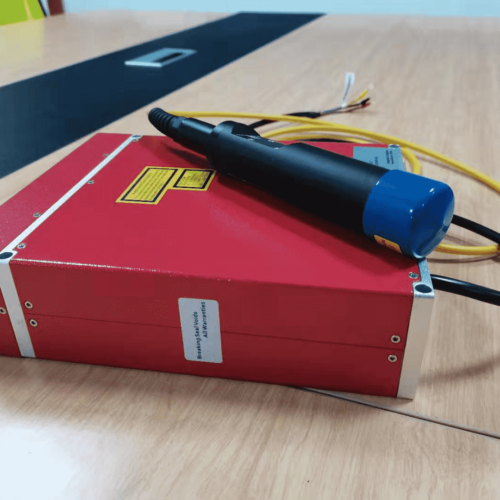

Raycus Laser Source

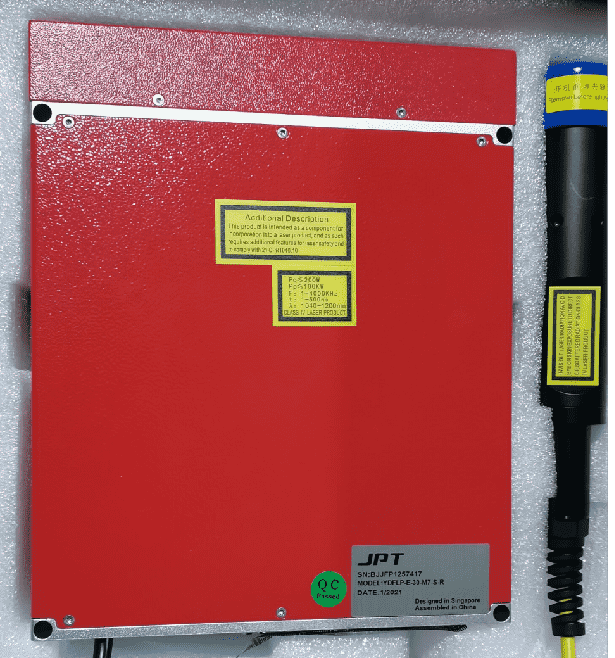

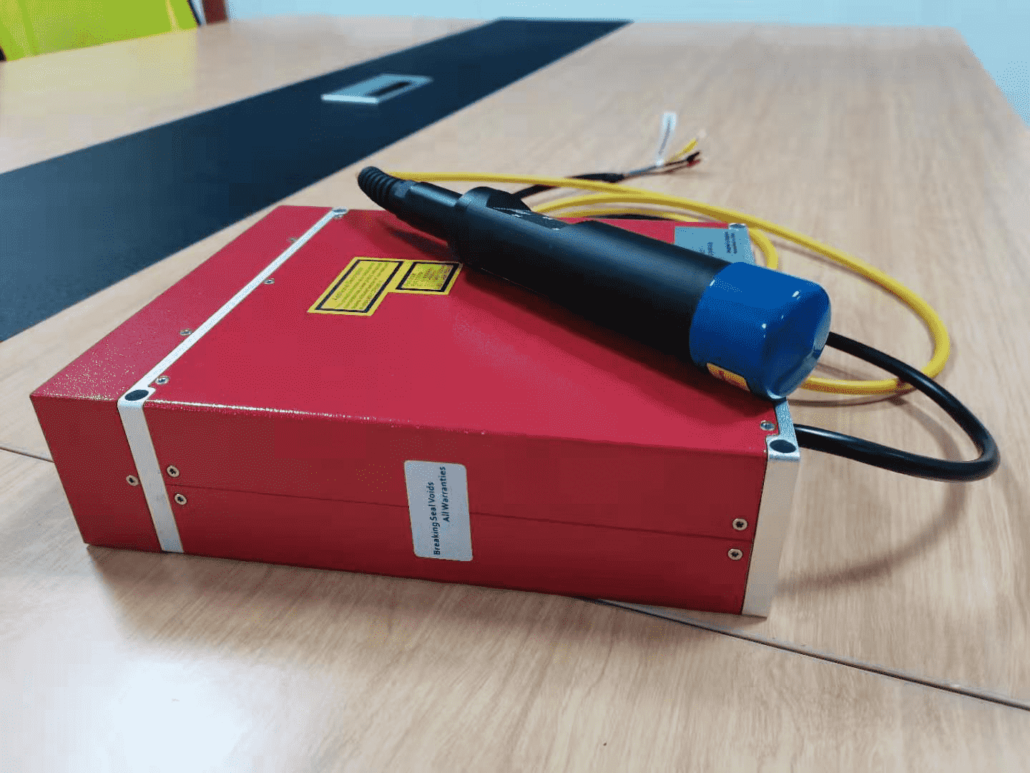

JPT Laser Source

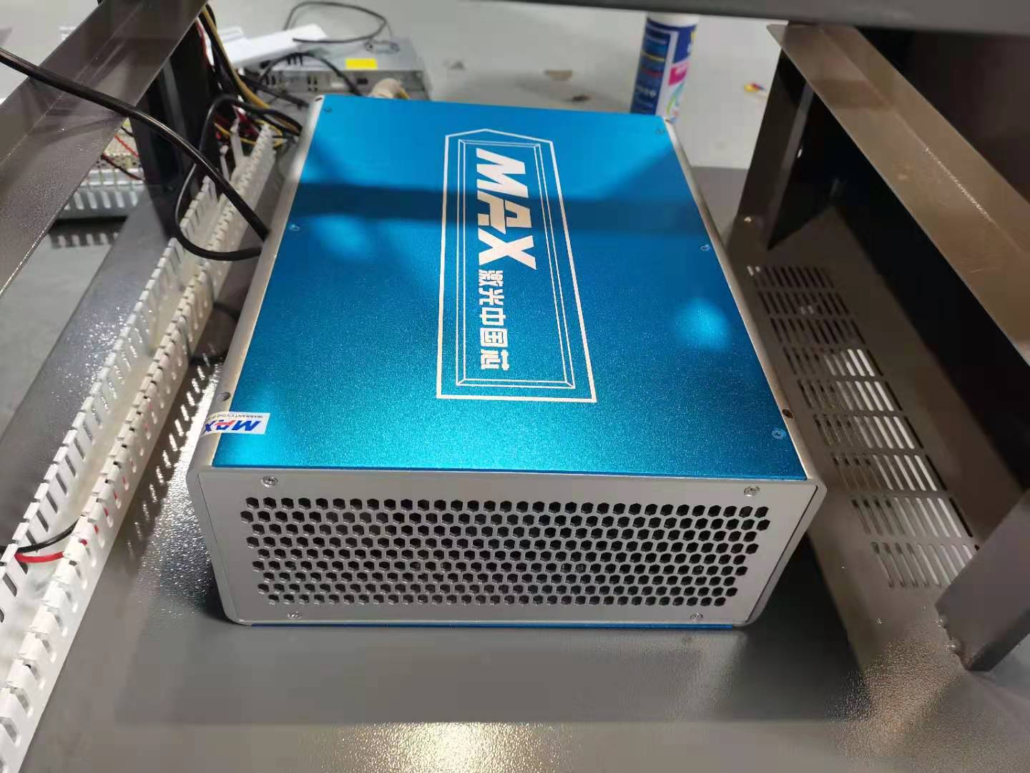

MAX Laser Source

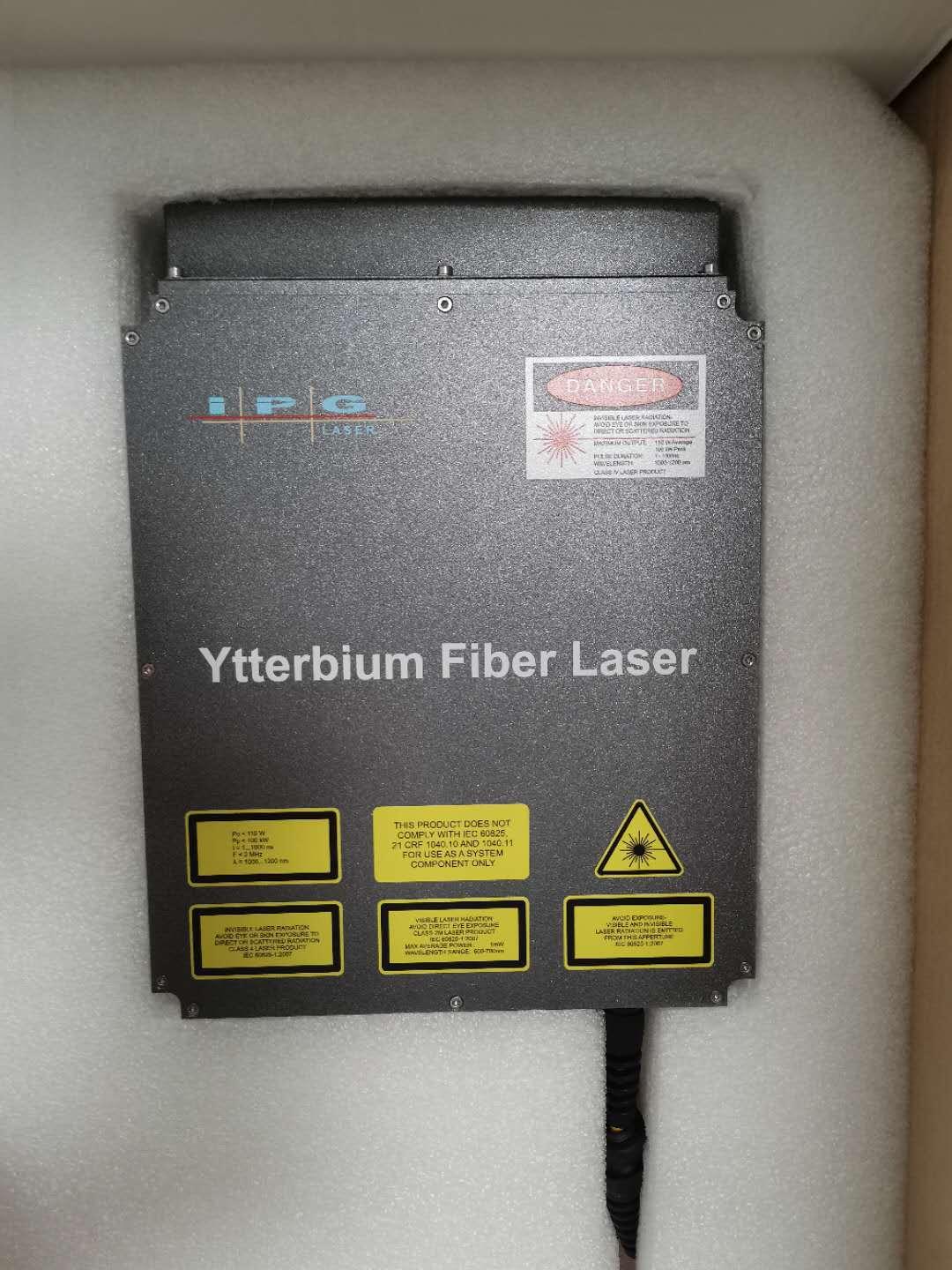

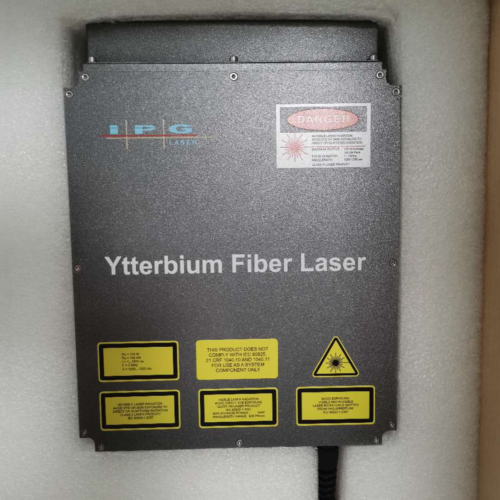

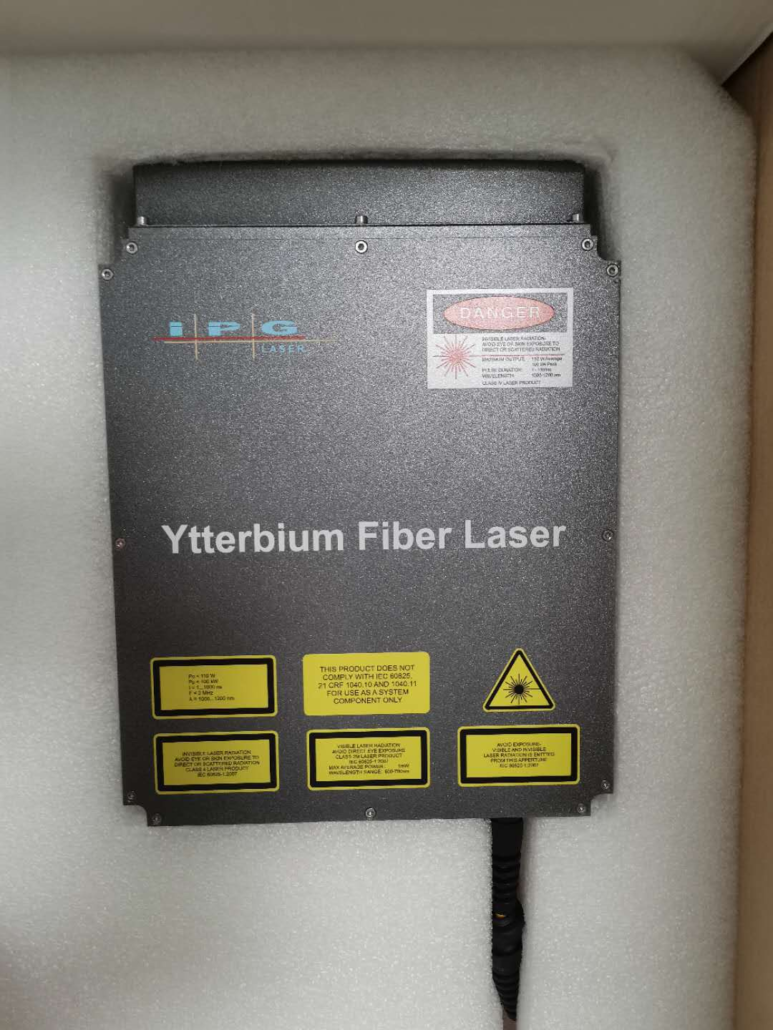

Germany Laser Source IPG

UV Laser Source

CO2 Laser Source

Specification(Raycus)

|

Average Output Power(W)

|

20W

|

30W

|

50W

|

|

Wavelength(nm)

|

1064nm

|

||

|

Repetition frequency range

|

30-60 kHz

|

30-60 kHz

|

50-100 kHz

|

|

Output power stability

|

<3%

|

||

|

Output characteristics

|

|||

|

Output beam diameter

|

7±1 mm

|

||

|

M²

|

<1.5

|

<1.6

|

|

|

Polarization state

|

random

|

||

|

Pulse Width

|

110-140 ns

|

110-130 ns

|

120-150 ns

|

|

Max single pulse energy

|

1mJ

|

||

|

Delivery cable length

|

3M (customizable)

|

||

|

Electronic control characteristics

|

|||

|

Power supply (VDC)

|

24

|

||

|

Power range (%)

|

10~100

|

||

|

Power consumption

|

170W

|

240W

|

340W

|

|

Other characteristics

|

|||

|

Dimension

|

260*340*120 mm

|

||

|

Cooling way

|

Air cooling

|

||

|

Operating temperature

|

0~40℃

|

||

After Sales Service:

1.All of our machine will be fully-checked by our quality control department before the shipment.We guarantee all of our laser machines have a one-year warranty (quick-wear parts notincluded).

2.Training details: operation principles, system and structure, safety and maintenance, softwarethe processing technique, and so on.

3. Numerous feedback from our clients have proven that our laser machines are stable inperformance with rare malfunction. However, we would like to handle it as follows oncemalfunction occurs:

a.We guarantee that we will give you a clear reply within 24 hours.

b. Customer service staff will assist and guide you to analyze the malfunction in order to locatethe cause.

c. If the malfunction is caused by improper operation on software and other soft faults, we willhelp solve the problem on line.

d.We will offer plenty of online supports, just like detailed technical and installation instructionsby email,video, telephone. (Training by team viewer)