We often find cleaning rust or paint challenging. Old-fashioned methods, like sanding or blasting, take a long time and are usually stressful. Chemical cleaning might also be messy and pose health risks. However, laser rust removal technology makes it easier and more efficient.

This article talks about how laser rust removal works. We will learn some fundamentals of laser cleaning. This information can help you choose a suitable device for your projects. Also, knowing each setting will help you keep your machine in good shape for a long time. However, if you have any questions, feel free to contact us.

What is Laser Rust Removal?

Laser rust removal is a non-abrasive cleaning method. It is usually used to clean different surfaces of rust and other dirt. It’s also known as a laser cleaner, laser rust remover, laser rust stripper, or laser de-rusting machine.

Two types of laser rust removal machines are generally popular. One is a portable hand-held laser rust remover. It means you can take it anywhere, making it suitable for small-scale uses. On the other hand, stationary laser cleaning machines are fixed and large. However, people often use hand-held rust removal laser machines.

Laser rust removal is a better cleaning method. Compared to other methods, it offers the following benefits:

- Laser cleaning is super accurate. It doesn’t affect the underlying surface.

- This method is super-fast.

- Laser rust removal, especially dry cleaning, doesn’t need chemicals. It also doesn’t produce waste. As a result, laser rust removal is eco-friendly.

- Laser cleaning is a versatile method. It can be used on various surfaces, such as metals, wood, and stone.

- This method is safe and reliable. Although the initial cost might be higher than another method, it is an excellent long-term option.

How Does Laser Rust Removal Work?

You can use laser tech to clean your workpiece in two ways: dry cleaning and wet cleaning. Both methods are widely popular in industrial uses.

Dry Cleaning

The laser emits high-intensity light beams when dry cleaning the rusted material. The rust on the material absorbs the light beams. This absorption rapidly increases the heat. As the rust heats up, it undergoes ablation, vaporization, and turning into gas.

The laser device controls this process to remove only the rust layer, leaving the surface almost unaffected.

As the name implies, this cleaning method requires no liquids or chemicals. As a result, it is environmentally friendly. Most laser rust removal cleaners are of this kind.

Wet Cleaning

Wet cleaning combines laser technology with a liquid solution, mostly water or a solvent. The method applies the liquid solution to the surface to be cleaned. This step can be done manually or automatically. However, the laser device emits light pulses onto the wet surface after using the liquid. The rest of the process is the same.

Wet cleaning is especially suitable for certain types of rusted surfaces. In these situations, damp cleaning is more effective than dry cleaning.

Important Parameters to Know About Laser Rust Removal Technology

You should know a few critical things about laser cleaning. Understanding them is crucial for getting rid of rust quickly and effectively. Knowing these factors will also help you keep your machine in good shape. Most importantly, it helps prevent the treated area from getting damaged.

Laser Power

Laser power is the energy output of the laser beam. It is usually measured in watts (W). Higher laser power offers a faster job. Both fiber and MOPA lasers are famous for laser cleaning. Fiber lasers are prevalent in continuous laser cleaning, while MOPA lasers are great for pulsed laser cleaning.

A laser power of 20-50W is suitable for lighter tasks. It provides precise cleaning without damaging delicate surfaces. A laser power of around 100W is perfect for medium-duty applications. It’s ideal for removing rust or paint layers. Finally, higher laser power, ranging from 1000W to 2000W, might be necessary for heavy-duty tasks.

Pulse Width

Pulse width, or pulse duration, is another critical parameter in laser cleaning. It determines the duration of time the laser emits energy during each pulse. It influences the amount of transferred to the surface.

Shorter pulse widths are excellent for precise cleaning tasks. They can deliver intense energy in a brief period and minimize heat buildup. Short pulse widths also reduce the risk of surface damage. In contrast, the longer pulse is suitable for broader areas. They are prevalent for cleaning larger surfaces in a single pass.

Laser systems may also have choices for either continuous or discontinuous pulse modes. In continuous pulse mode, the laser sends out a steady stream of waves. Discontinuous pulse mode, on the other hand, has waves that come and go. It works great for cleaning delicate things.

Laser Frequency

Laser frequency is usually measured in Hertz (Hz). It tells you the frequency of laser pulses emitted over a specific duration. This parameter directly impacts the speed of the laser rust removal process.

Higher laser frequency refers to the number of laser pulses generated at the output. It generally improves the intensity of the laser’s interaction with the surface. It means the higher the frequency is, the finer the surface. The higher frequency allows the surface to be cleaned more quickly and effectively.

Output Spot Area

The output spot area of a laser is also a critical parameter. It is the size of the laser beam where it interacts with the surface. It directly influences the cleaning process.

High-precision cleaning tasks generally need a smaller output spot area. This is because it accurately targets rust or paint and removes it without affecting surrounding areas. Conversely, larger surfaces need a larger output spot area. It makes the process quicker. It is widely used in industry-scale jobs.

Choosing the right output spot area depends on your project requirements. You can also consider surface intricacy, desired cleaning speed, and other factors.

Laser Scanning Speed & Angle

The laser scanning speed measures how fast the laser moves over the surface. On the other hand, the angle tells you the angle of the laser beam.

The higher scanning speed means faster cleaning. Overall, it reduces downtime and increases productivity. On the other hand, optimal angles ensure thorough coverage and consistent results. The correct angle is also necessary for preventing uneven cleaning or missed spots.

Frequently Asked Questions

Is laser cleaning better than sandblasting?

Both are commonly used in work. However, laser cleaning is a more accurate method than sandblasting. Also, it doesn’t need any abrasive particles to clean the surface. So, a laser machine for cleaning rust is good for the environment.

Sandblasting, on the other hand, needs abrasive particles. These particles could hurt the surface of your material. They produce dust. Thus, they are not eco-friendly. The good thing about sandblasting is that this method is cheaper than laser cleaning. However, considering long-term benefits, a laser rust cleaning machine is better.

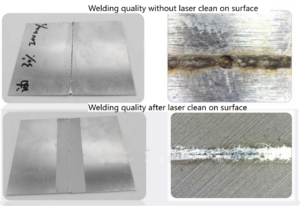

Does laser rust removal damage metal?

No, when done correctly, it doesn’t damage the metal. The laser beam goes after the rust without hurting the metal below. It works by vaporizing the rust, leaving the metal intact.

This method is accurate and efficient. However, using the correct laser parameters is essential to prevent overheating.

How long do laser cleaners last?

Laser cleaners typically have a lifespan of about ten years. This can vary based on how well you have maintained them. Besides, the environment in which you have used them also matters. High-quality parts can help extend their lifespan. On top of that, they need to be cleaned, stored and inspected regularly.

What can you clean with a laser cleaning machine?

A laser cleaning machine can clean a variety of surfaces. It’s excellent for rust removal, paint stripping, and removing grease and oil. It works on metal, stone, wood, and more. You can use it on car parts, statues, machinery, and historical artifacts. The laser rust cleaning machine is precise and won’t damage delicate surfaces.

Expert Advice

There are hundreds of brands or manufacturers out there. It sometimes becomes tricky to choose from all these options. To ensure efficient and effective cleaning, you must select the right one.

Firstly, consider the laser power. Note that higher laser power means faster and better rust removal. In this case, consider how thick and severe the rust is. This typically helps decide the correct power level. More power removes rust quickly. It’s like matching the right tool to the job.

Secondly, shorter pulses clean small areas precisely, while longer pulses are better for big spaces. Get a machine with adjustable pulse lengths. It should suit different cleaning needs.

Safety features should also be considered. Laser rust removal machine uses powerful light beams, so safety is vital. Look for machines with interlock systems and protective enclosures. Most hand-held laser rust removal machines come with a protective case for the laser gun.

When choosing a hand-held laser cleaning machine, consider its ease of transportation. Check the weight, rolling mechanism, and ease of use.

Choose a machine with easy-to-use controls and screens. Check whether you can adjust the settings and monitor the cleaning process.

Pick out a type that only needs a little upkeep. All HiSpeed laser rust removal machines come with perfect finishing. That’s why you only need a little upkeep. Lastly, make sure you correctly weigh the short-term costs and long-term rewards.

Contact us today to learn more about our laser cleaning machines and how they can meet your needs. Our team of experts is always here to help you find the right solution.