Laser engraving is a very popular and versatile method. It is indeed a profitable business. However, you must know how to decide your project’s laser engraving cost. It involves several factors that you must take into account.

The demand for laser-engraved items is growing fast; in 2024, it will be at an all-time high. People love personalized gifts, unique decor, and products. Many businesses are also using laser engravers or cutters for branding or marketing.

These factors will be familiar to you in this article. Ultimately, you can decide on the laser engraving pricing for your project. This article also highlights some of the best-selling small laser-cut items of 2024.

Overview of Laser Engraving Cost

Laser engraving prices vary widely. The laser engraving cost mainly depends on the engraving’s material size, design, and depth. On average, laser engraving ranges from $5 to $100. Simple designs on smaller parts are usually less expensive, typically costing $5 to $20, depending on the type of engraving. On the other hand, detailed work or larger projects cost more, even more than $100.

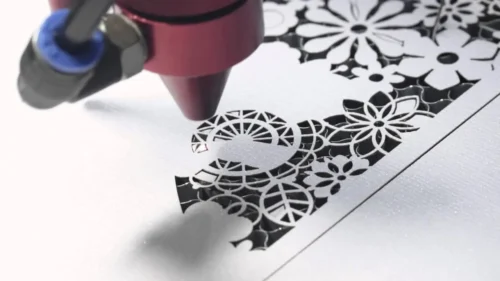

You might be wondering about other traditional methods, like CNC machining. CNC machining, such as router machines, might cost less than laser cutting. However, you must consider creating detailed designs and accuracy. Is it possible with router machines? The tiny laser beams can create designs at a microscopic level. As a result, the engravings you get are highly accurate and precise.

Another crucial aspect is the ability to work with fragile components. CNC routers cannot handle fragile things, but laser engravers can. Because of these capabilities, laser cutter projects require higher costs than CNC routers.

How Much to Charge for Laser Engraving

If you want to run a successful business, it is crucial to understand how to price laser engraving jobs. There are several steps to ensuring profitable business and customer trust.

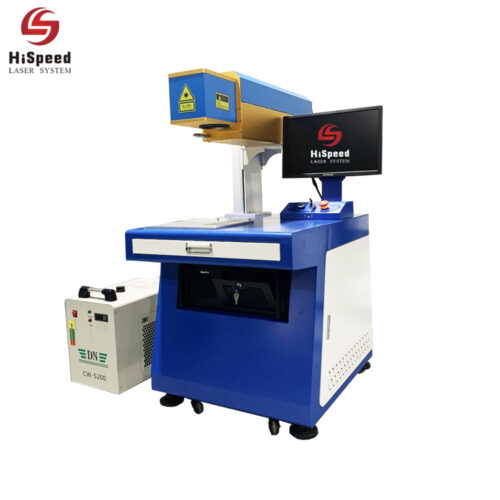

Laser Engraving Machine Price or Laser Engraver Cost

The first thing you must consider is the price of a laser engraver. High-quality laser engraver machines can range from $2000 to $20,000. You can divide the machine’s price over its lifespan to find the cost per part.

For example, let’s say your laser engraving equipment costs about $10,000, and you expect it to last five years. This means you allocate $2,000 annually. If you handle 1,000 projects in a year, that’s $2 per project toward your machine price.

Material Costs

The next thing you will count is the material cost. Wood, acrylic, metal, leather, and glasses have different price ranges, each with various grades and price ranges.

For example, a wood-cutting board may cost $10, while a metal one could cost $5. Add these costs to the total laser engraving cost.

Labor Costs

Labor costs are one of the most critical factors that you must calculate carefully. It depends on whether you are calculating on an hourly basis or a project basis. Note that an average project takes only 30 minutes to finish. For example, if your labor rate is $25 per hour, each project will cost $12.5.

Laser Engraving Machine Wear and Maintenance

Laser engravings need periodic check-ups and upkeep. You may need to clean the lens, replace the parts, or make occasional repairs. When pricing laser engraving, you must consider this factor as well.

For example, you can estimate the upkeep and repair cost of $500 annually. Then, you can divide this value by the number of projects you aim to finish in a year. Finally, you can add the total value to the final laser cutter project cost.

Adding Profit Margin

Finally, your profit margin is your business’s actual revenue. The typical profit margin for laser engraving projects ranges from 20% to 30%. Some fancy items may have a profit margin of up to 50% to 70%.

Can You Make Money with a Laser Engraver?

Laser engraving and cutting are versatile and creative technologies. This tech is very accurate and surprisingly fast to cut materials. In the modern world, they are very famous in various applications. However, can you turn this opportunity into a profitable business? The answer is yes!

There are lots of business ideas that you can accomplish with laser engravers. In this case, HiSpeed laser engravers are widely popular for small to large businesses. These machines have a proven track record of making a quick return on every investment.

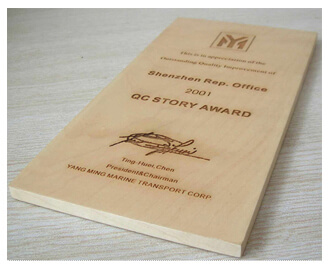

Laser engraving is indeed a profitable business. It typically adds value to everyday items. For example, think about a cutting board you use in the kitchen. It generally costs $10 or less. If you personalize this item, you can sell it for $40 or more after engraving. You could add names, logos, or quotes, and people always love it.

Similarly, you can make other things, such as jewelry, leather, or even booze bottles, more valuable. This can make them worth three to four times their original cost.

Laser engraving machines are high-speed and efficient. They are ideal for bulk production. Therefore, they are perfect for any business. In modern laser engraving machines, you can also integrate them into production lines. These machines use conveyor systems to perform continuous and high-speed operations.

Best-Selling Small Laser Cut Items

Laser engraving is very popular nowadays. Various Enthusiasts use this technology to create personalized items. You can make a wide range of decor and customized items. You can look for various projects online if you are interested in business. However, this section has brought you the best-selling small laser-cut items in 2024.

Laser Engraved Liquor Bottles

Laser-engraved booze bottles make great gifts and event souvenirs. They are fantastic for special parties, business gatherings, and weddings. People love them for their unique patterns and customized designs. However, the laser engraving cost for these items mainly depends on the complexity of the design.

Laser Cut Signage

Custom signage is excellent for home decor, offices, and events. People often use wood, acrylic, and metal to make custom signage. The laser cutting rate, in this case, depends on your design, the material used, and the thickness. In general, wood signage is cheaper than metal signage. Signage is indeed the most popular laser cutter project for small businesses.

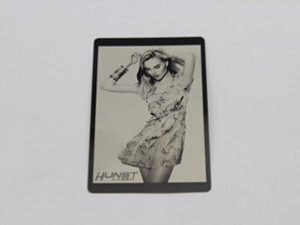

Laser Engraved Jewelry

Everyone loves to have personalized items. However, if it is jewelry, then personalization becomes more critical. Customized jewelry is often a favorite choice. People usually engrave initials, dates, or symbols to make each item unique. Well, the jewelry and design material typically affect the laser engraving prices.

Laser Engraved Wedding Cards

Laser-cut wedding cards are fancy, and people love them in 2024. Especially couples love these items so much more than old color-printed wedding cards. Laser etching can be cheaper per card when you buy many of them, making them beneficial.

Laser Engraved Decorative Items

Personalized home decor, such as coasters and ornaments, continues to sell well. Laser-cut projects are great for gifting or seasonal sales. Material choice and design trends influence laser engraving prices.

Laser Engraved Leather Items

Most people who receive laser-engraved leather gifts receive wallets, belts, and bags. The designs, brands, or titles etched on these generally make them more valuable. In this case, the laser cutting rate varies by leather type and design complexity.

Laser Engraved Metal Nameplates

Nameplates are widely used in offices and industries. In 2024, people preferred laser engraving over dot peening or other methods. The laser engraving cost depends on the material and finish. Thus, they are a staple for businesses.

Frequently Asked Questions

How Much Do You Charge for a Laser Engrave Cutting Board?

Laser engraving on a cutting board costs between $15 and $50. For example, a 14 x 24-inch cutting board costs around $35 to $40. The cost depends on the type of wood, design size, and complexity. Usually, people love to do personalization on cutting boards, such as engraving names or logos. This extra work may affect the price as well. If you are a business owner, you can offer discounts for bulk orders to your customers.

How Much Does Engraving Cost Per Letter?

Laser engraving costs per letter typically range from $0.5 to $2 or more. The cost generally depends on the type of material, font style, and engraving depth. Marking on wood or acrylic is usually cheaper than marking on metal. Simple fonts or smaller letters cost less. However, adding cartography or a special design may increase the cost.

What Is the Startup Cost for a Laser Engraving Business?

Starting a laser engraving requires not just a laser engraver but also everything. First, you must find a place where you will organize your business. Next, you will have to choose an appropriate laser engraver machine. Then, you must prepare the materials, software, and other expenses. In total, this cost generally ranges from $5,000 to $15,000.

If you are doing DIY projects, you may manage it for $1500. If you plan to do high-end businesses, this cost may reach up to $20,000.

How Much Is the Cost of a Laser Engraving Machine?

A low-end laser engraving machine generally costs from $300 to $1,500. The mid-range laser engraving machine may cost from $2,000 to $10,000. On the other hand, the high-end laser engraving machine may cost over $20,000. Actually, the price varies depending on the type of laser machine, power, and size. Fiber laser engraving or cutting machines are usually more expensive than CO2 laser engravers.